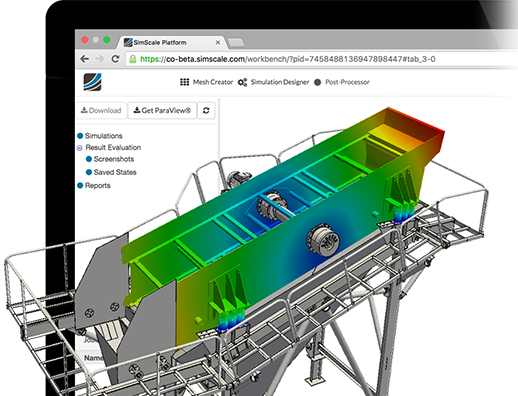

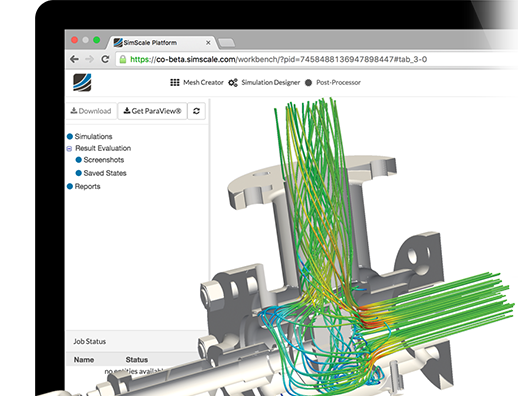

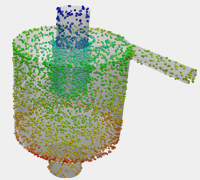

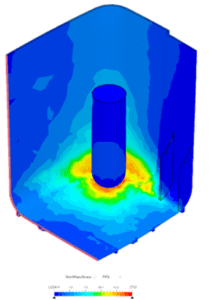

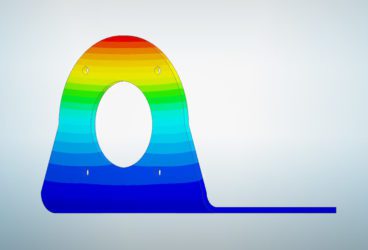

SimScale enables rapid iterative physical simulations of complex multi-body assemblies in a simple-to-use, cloud platform. This toolset can be used by equipment OEMs and integrators to drive performance, increase reliability, enhance safety, and ultimately reduce the cost of production.

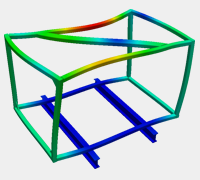

In the industrial equipment industry, customer expectations and government regulations are related to strength, speed, safety requirements, reliability, and endurance under different operating conditions.

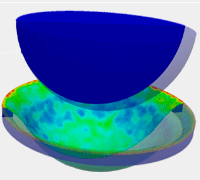

SimScale helps optimize the design early in the design cycle using AI-powered simulation to deliver fast, valuable insights.. This ensures the production of high-performance machinery with a shorter time-to-market and reducing costs for physical testing.

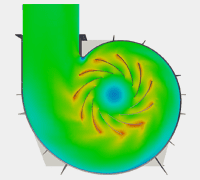

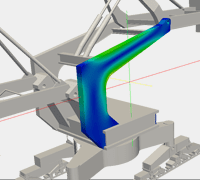

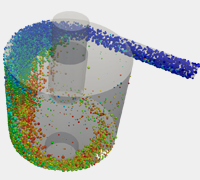

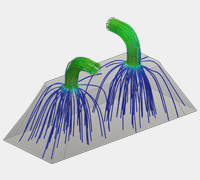

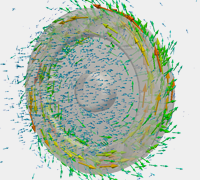

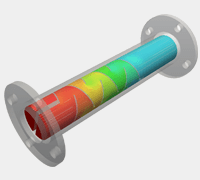

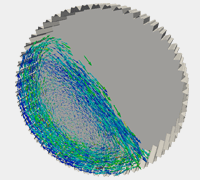

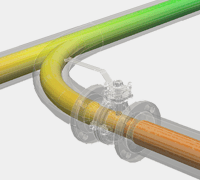

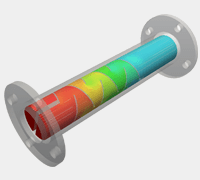

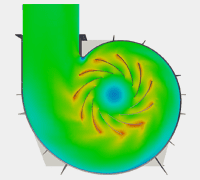

Perfectly suited for simulating all types of machinery and industrial equipment — with mounting, clamping, adjusting, rotating and other elements — SimScale is a simulation tool used by numerous industrial equipment manufacturers across many different industries, including construction, mining, automotive, chemical, water management, turbomachinery, steel industries and many more.

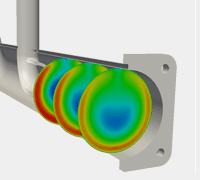

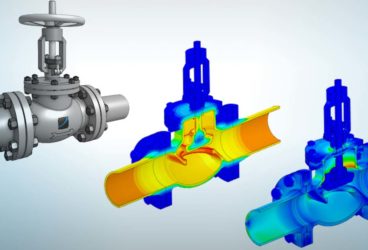

Simulation is a critical part of industrial plant design, with process engineers needing to get insights into physical effects as early as possible as companies seek more sustainable, cost efficient design, , all while striving for operational efficiency.

The need for better industrial machinery and components, larger units, complex installations or industrial equipment is pushing for innovations that can speed up the engineering design process.

SimScale’s cloud-native platform uniquely combines physics-based simulation with physics AI predictions that allow plant engineers and mechanical designers to utilize simulation tools to optimize their designs early in the design process.

Our latest eBook explores how cloud-native simulation is transforming industrial machinery manufacturing challenges into opportunities, including:

Download it for free by clicking the button below.

Customer Success

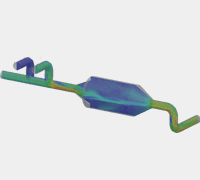

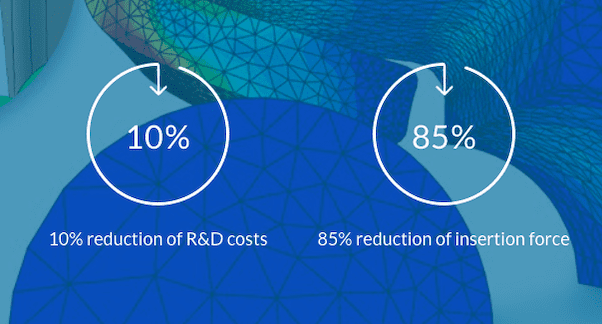

In this analysis, ITW deployed cloud-based engineering simulation at an enterprise level to study and optimize an automotive engine bay fastener used to connect pipework to metal housing. Using SimScale’s structural analysis, ITW optimized the fastener design, lowering the insertion force by 85% and reducing their R&D costs by 10%.

Check out all the success stories of our customers in the machinery and industrial equipment industry, including ATAG and Hazleton Pumps.

See All Stories

Sign up for SimScale

and start simulating now