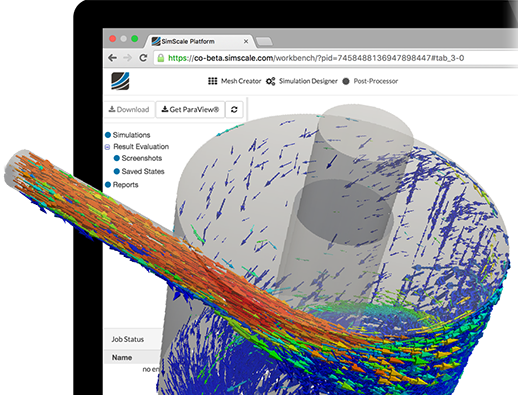

In addition to chemical plants, chemical processing also occurs in oil refining, natural gas processing, polymer and pharmaceutical manufacturing, food processing, and water and waste water treatment. As the largest industry in the world, with more than $770 billion in annual sales, the chemical industry relies on chemical processing to find solutions related to energy efficiency, process improvements, cost reduction, plant optimization, automation, and safety performance. Companies operating in the chemical processing industry are always focusing on increasing product performance, supporting green engineering, and increasing the overall progress of the industry. SimScale provides you with powerful capabilities and a wide range of features to use towards your simulation projects, and frees you up from the large upfront investment of traditional simulation software by scaling to your needs so you can start risk-free with CAE.

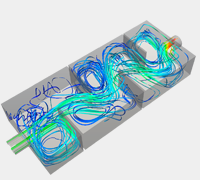

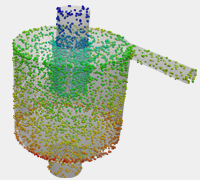

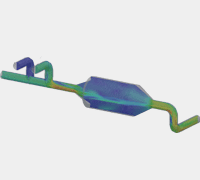

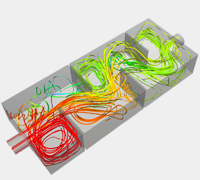

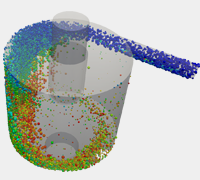

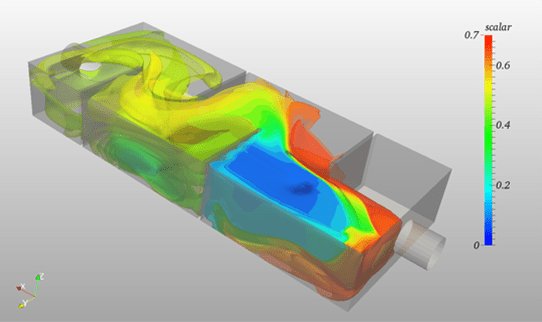

An important stage in water purification is disinfection. One of the ways is to pass the water through a maze channel to create turbulent recirculation regions where a disinfectant can then be introduced to purify the water. In this project, a water purification process in a maze channel reactor was simulated.

Sign up for SimScale

and start simulating now