Spark is an innovative technological company established in 2012 with the aim to develop excellence in the field of video surveillance, in line with the local mechanical engineer tradition. Spark believes that safety is a primary human right. That’s why the company’s team uses innovative technology to make the world a safe and smart place for everyone. The company has developed three product lines (Nitida, Professional, Smart) and a Video Management System (recorder and client interface), providing tailored and customized CCTV solutions.

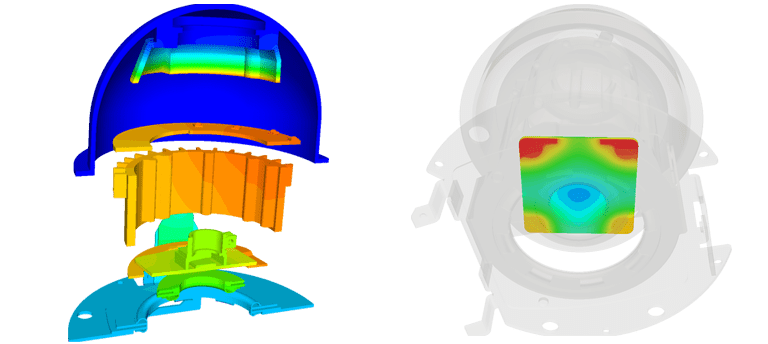

Spark wanted to analyze the temperature contour on the heat sinks and on the image sensor board for each of their design versions. This way they could determine which of their designs best matches the required operating conditions and as such can be prototyped.

The project involved running transient FEA heat transfer simulations to analyze the temperature distribution on a surveillance camera considering heat generation from both the LEDs inside as well as from the image sensor. Two design approaches were validated considering different heat sinks and different convection configurations.

We are aware that quality is something you have to work hard for. It's a long path consisting of trials and errors, investments, and iterations based on customer feedback. SimScale is a tool supporting us on that path. We have found an active and highly specialized technical support in SimScale which was fundamental in helping us to get started with the platform.

Massimiliano Marchionni

Technical Product Owner

In order to be able to assess the temperature contour over time due to the different heat sources inside the camera, Massimiliano Marchionni, Technical Product Owner from Spark ran 4 different transient heat transfer analyses. The CAD was then meshed using the automatic Tet-dominant algorithm available on SimScale which created meshes with around 1.2 million nodes.

The design validation was then performed for two setups and for two different camera designs with the help of a transient heat transfer analysis type. The main purpose of the simulation was to assess the temperature distribution on the heat sink which is located inside the device. The heat sink’s role is to dissipate the heat generated from the LEDs during operational conditions.

The other goal behind the simulations was visualization of the temperature distribution on the image sensor’s board and how it is affected by the heat dissipated from the heat sink and the other camera components.

Each simulation contained 2 different volumetric heat sources, one assigned to the LED and the second one on the image sensor. All air exposed walls were assigned a boundary conditions that modeled convective heat transfer to the exterior, taking into consideration different transmissibility coefficients.

The simulations were then performed for a gap time of 1500 seconds and with 32 cores. Each one took in average 130 minutes to finish.

“We are using SimScale to drive mechanical decisions during design time. Our mechanical engineers use SimScale to test new solutions and to choose the one with a better heat distribution. In particular, we are not interested to estimate the exact temperature in critical areas but instead, we use SimScale to find bottlenecks in heat dissipation and to confirm our thermal solutions by comparing different 3D models and different materials,” said Massimiliano Marchionni, Technical Product Owner at Spark.

The Heat Transfer simulations performed in the cloud with SimScale gave Spark’s team valuable insights into the thermal performance of their surveillance camera. Not so obvious thermal issues were identified in one of the proposed designed. The possibility to assess the heat sink configuration in the early phase of the design process, was of great value to Spark, allowing them to speed up the process of prototyping the design version which is the closest to the final product.

By not having to run physical tests for the two initially proposed designs, Spark Security could save 75% of their time running all the 4 configurations simultaneously in the cloud.

“The real value of using SimScale comes down to the working days we saved on managing thermal issues in case we would have found them first after mass production. I see SimScale as a form of prevention,” said Massimiliano.

Sign up for SimScale

and start simulating now