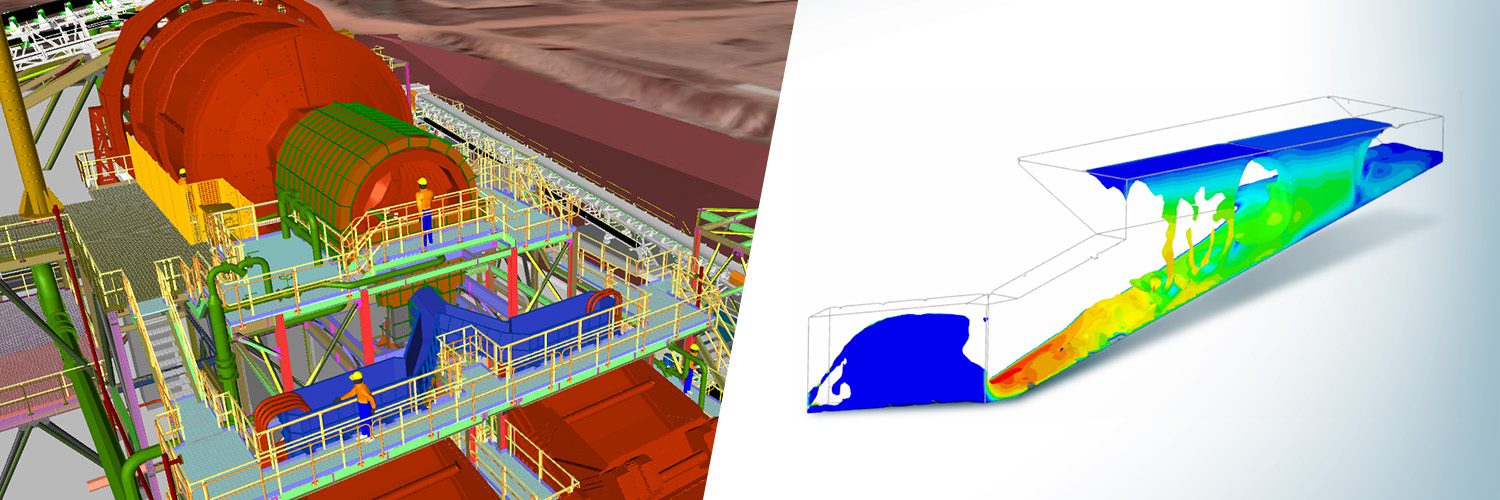

Zenito is an independent engineering consulting firm for mineral processing plants and infrastructure projects. It comprises a group of professional engineers with considerable and varied experience in the mining industry specializing in the design of mineral processing plants and associated infrastructure. Every project is different, and Zenito’s boutique engineering team lends itself to graphite, lithium, gold, iron ore, copper, lead, and zinc-based projects.

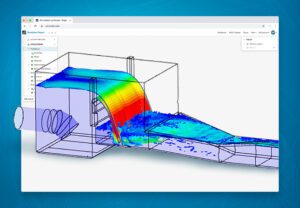

Zenito specializes in the design, procurement, and construction management of mineral process plants, from raw ore from the mine to the refined product for market sale. This involves process stages with dry materials handling and wet slurries (crushed rock suspended in water). All designs are bespoke and are pre-fabricated and sent to remote mine sites for installation. Physical testing of designs before installation and commissioning is not typically feasible which is where the use of engineering simulation using SimScale becomes critical.

Michael Jeffs is a Senior Mechanical and Project Engineer (CEng IMechE) at Zenito specializing in piping and fluid mechanics with 19 years of experience in minerals and industrial processing and leads the multi-discipline teams designing minerals processing plants at Zenito.

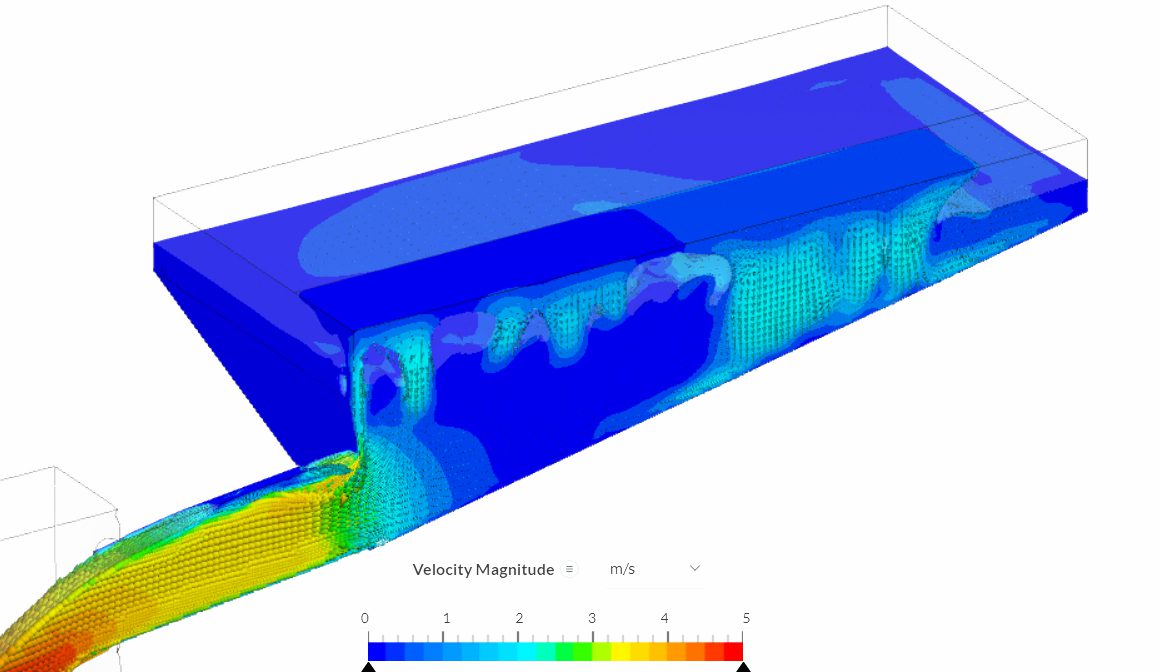

A primary use case is multiphase simulations of process slurries (crushed rock suspended in water). These cases are difficult to model and predict using calculations and empirical correlations alone and require high-fidelity engineering simulation to solve. Michael and his team have been simulating and analyzing the flow of these slurries to ensure that the turbulence and velocities are high enough to keep particles in suspension, while not inducing high wear on the flow structures.

Using SimScale provides the team with the ability to produce solutions to complex problems for our clients so that we can deliver their performance with confidence. The SimScale platform has been easy to use and provides a complete solution to our CFD needs. SimScale’s technical training and support were exceptional and were key to our project’s success, and the upskilling of our team.

Michael Jeffs

Senior Mechanical and Project Engineer (CEng IMechE)

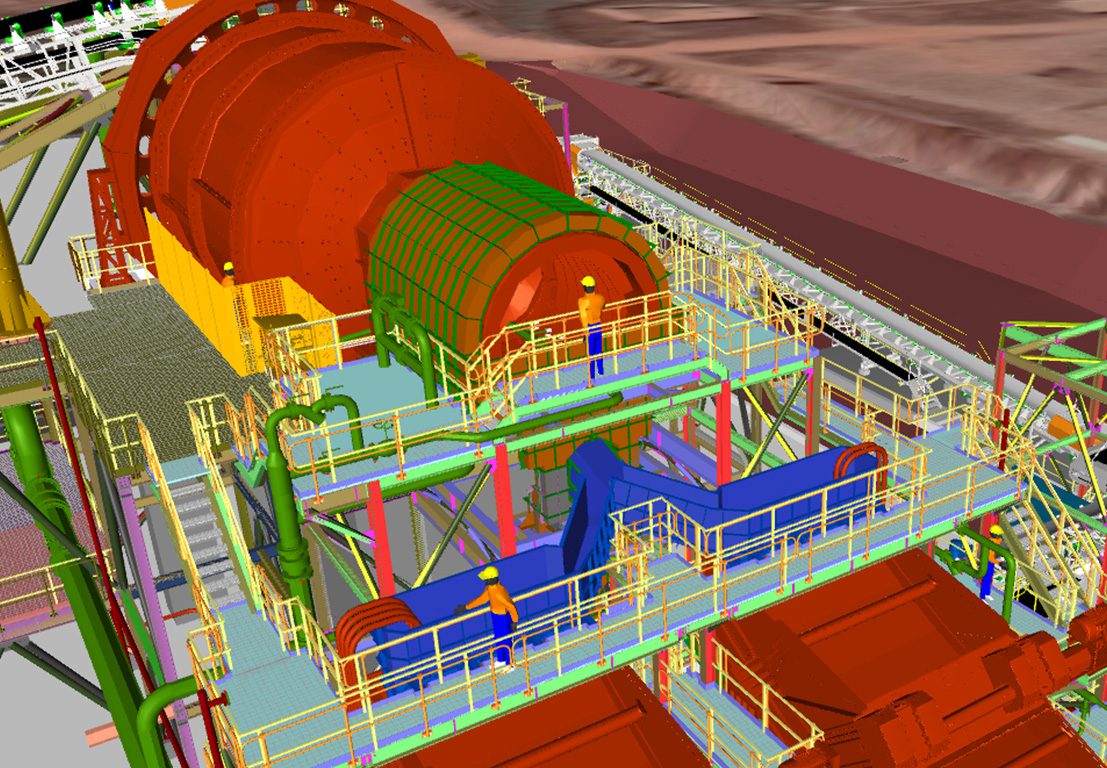

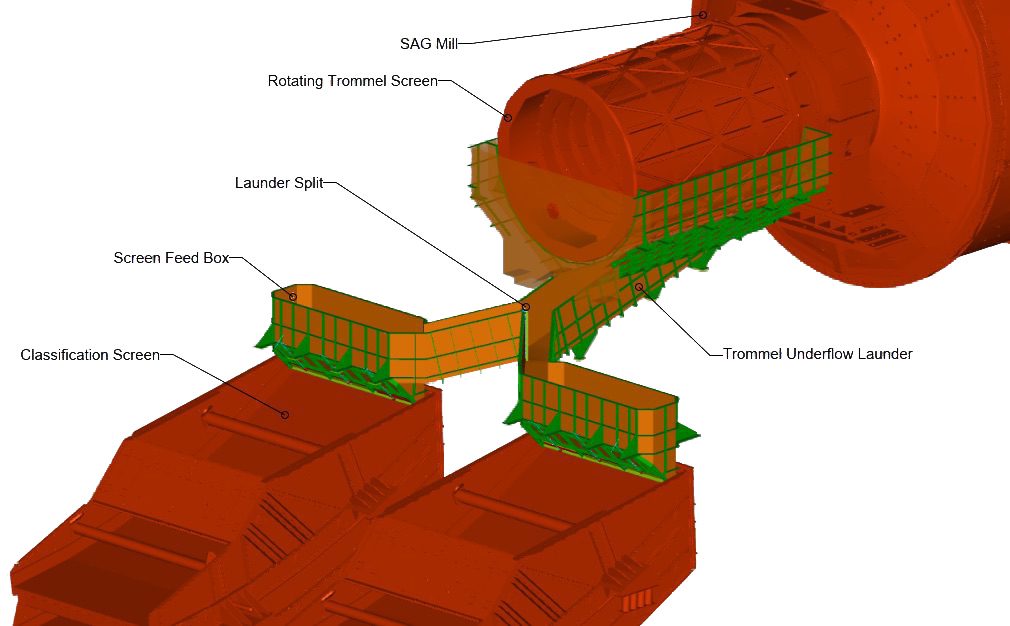

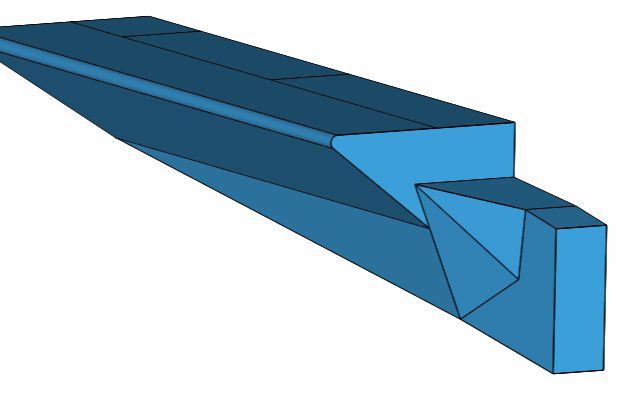

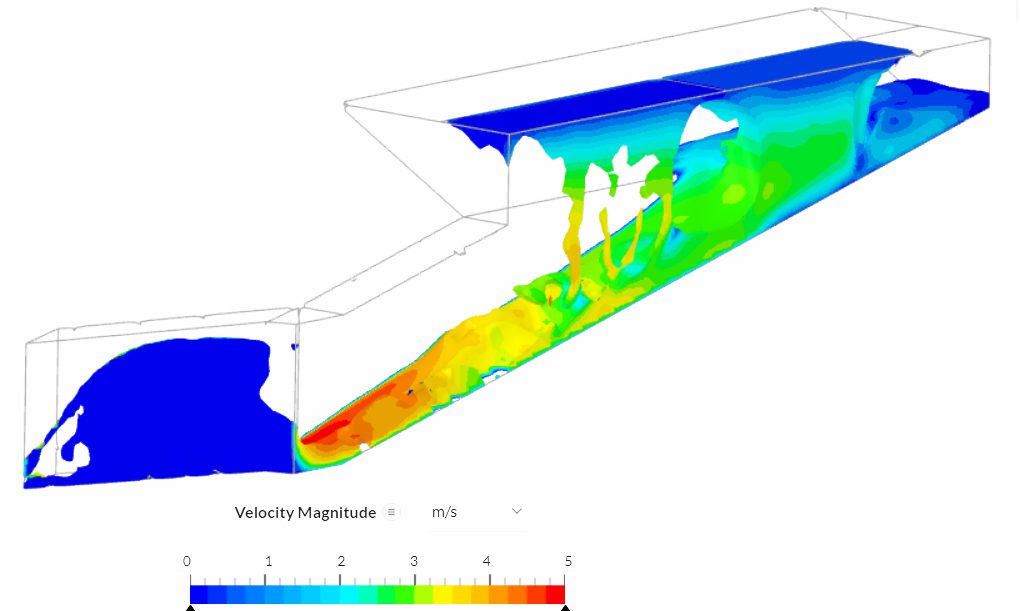

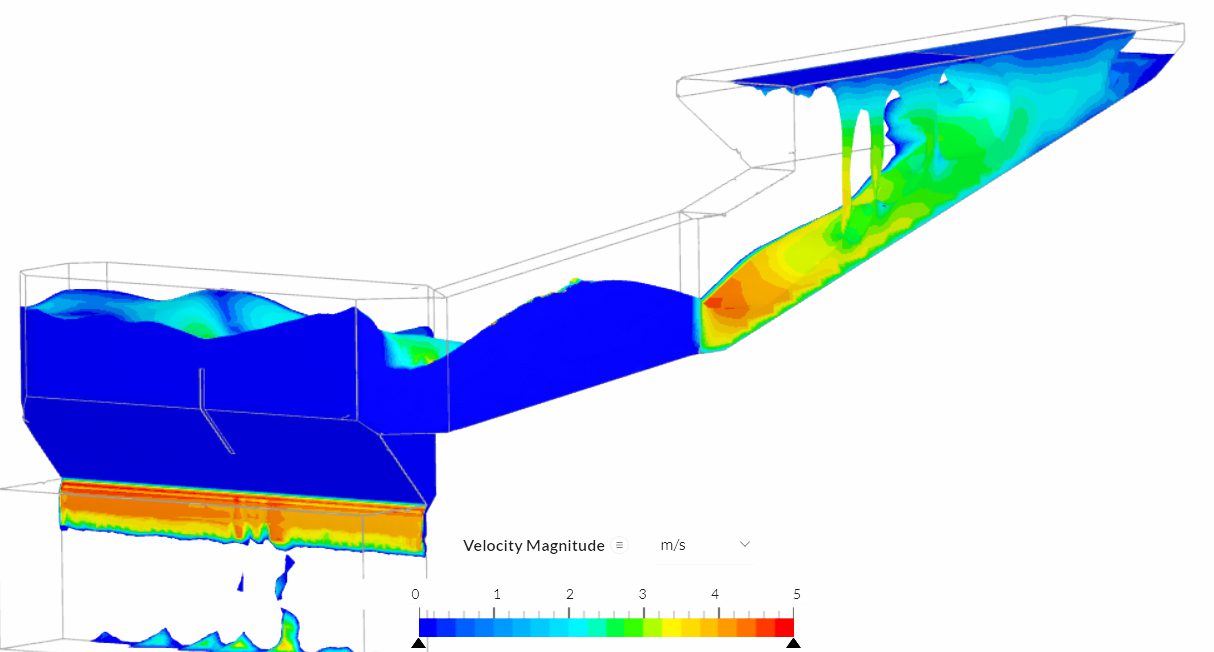

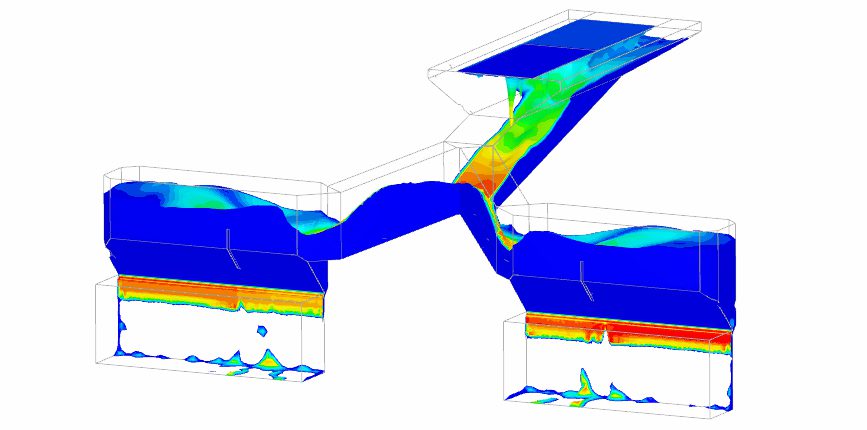

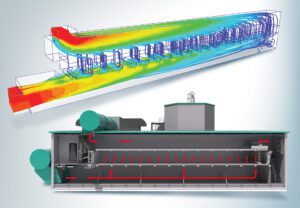

A SAG mill is used to grind and crush large pieces of rock into smaller pieces of rock, gravel, or dust. It is commonly used in the mining industry. An efficient way to transport this crushed material for further processing is as slurries in an open channel, called launders. Launders are subject to intense wear and tear from the slurries and are sensitive to the design as they utilize gravity for flow. The design of a launder is paramount to its flow efficiency, maintenance costs, and hence lifetime operation. A recent project required gravity laundering of iron ore slurry needing high velocities to keep dense iron ore particles in suspension during flow. The outlet onto the screens needed to be well mixed and uniformly distributed across wide screen decks. The design was constrained by the available gravity head and that the flow needed to be split.

An initial concept was to have a simple collection box for the slurry with a pipe outlet. CFD simulations in SimScale showed that the pipe outlet does not flow well enough and that the box fills up too quickly. The low flow velocities in the pipe would cause particle settling and testing various transition sections from box to pipe does not improve the flow significantly.

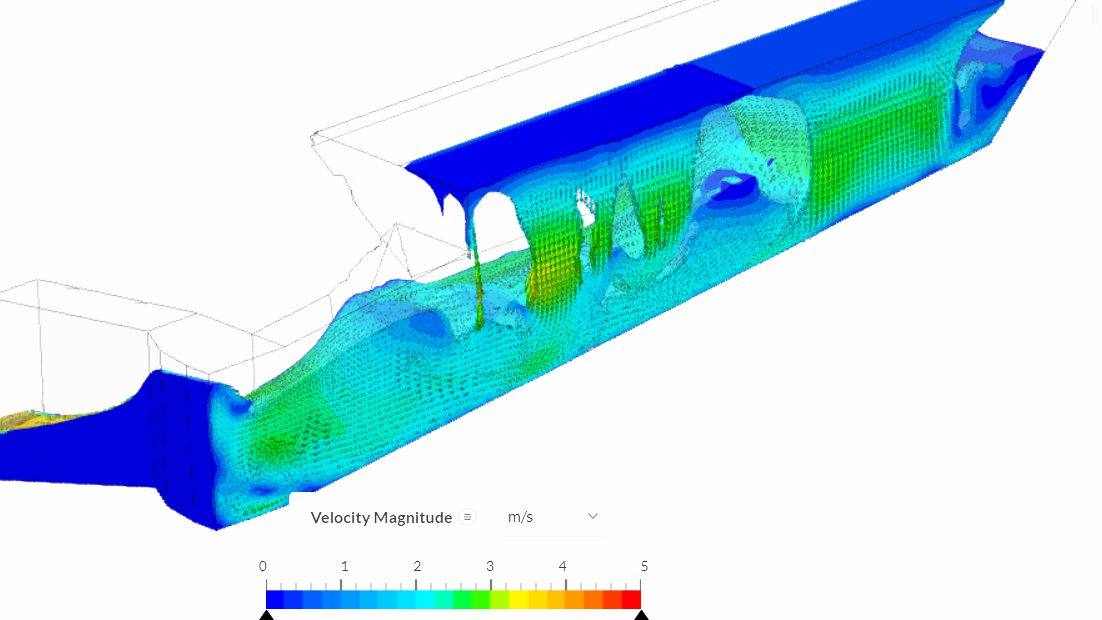

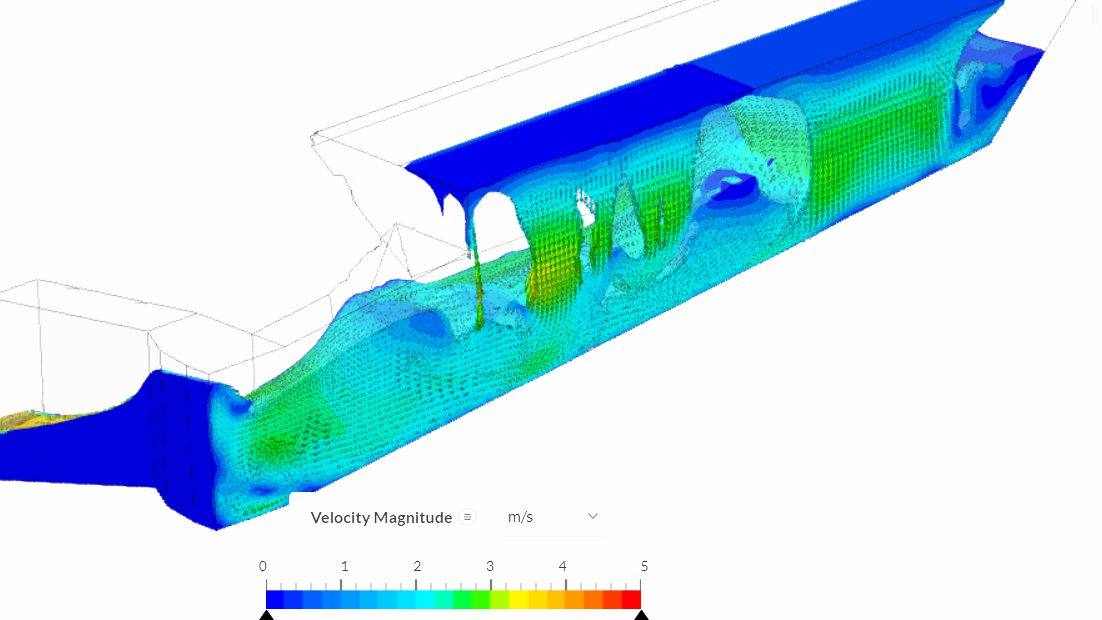

An open channel launder offers improved performance over the previous pipe design. In the current concept, a tapered outlet is somewhat restricting flow and a tee-branch used to split the flow is also inducing flow restrictions. This design still shows low velocities, however.

A change from a tapered outlet at the front of the box to a side collection of flows is added. The tapered outlet is still restricting the flow somewhat. However, the downstream tee-branch needed to split the flow is too restrictive and causes the flow from the box to backup.

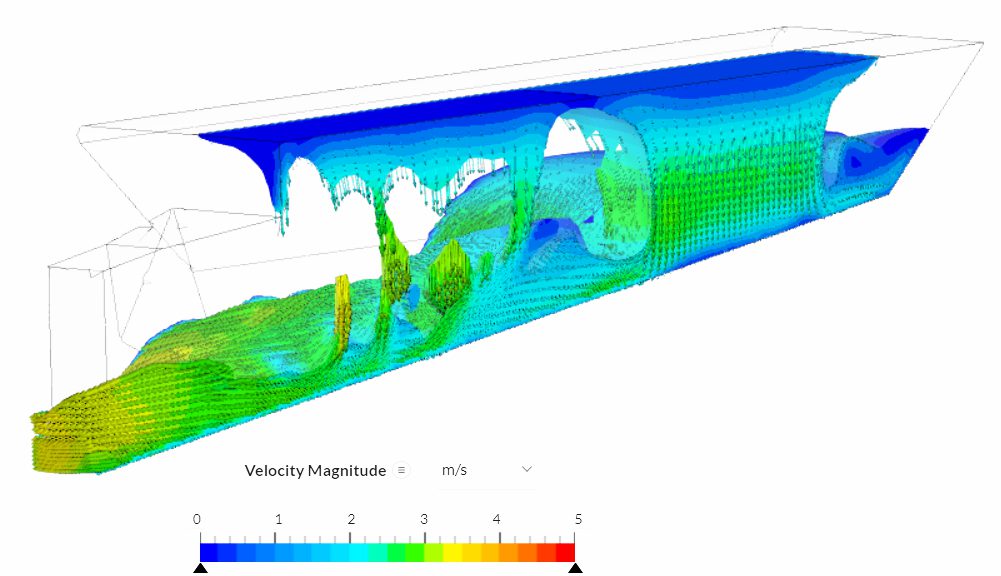

A final design concept has a steeper flow with no transition or taper leading to the launder. A V-split replaces T-split at the outlet for splitting the flow and the overall multiphase flow is much improved. Velocities are high after initial acceleration and considered acceptable.

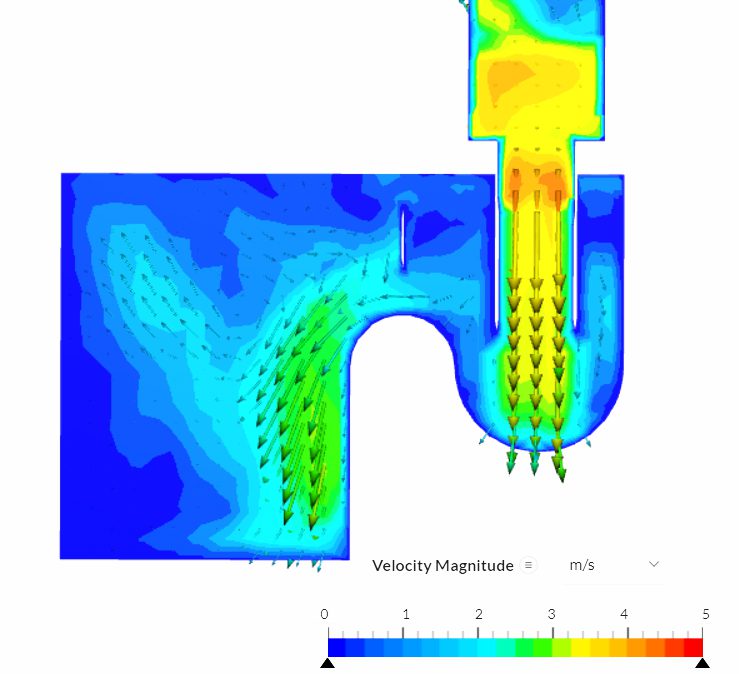

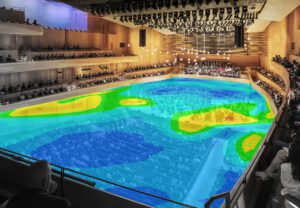

The operation of the feed box which is used to pre-mix the solid feed (crushed material) with water before it is presented as slurry to the screen (box).

An initial concept for the screen feed box was a typical collection box with down pipes to distribute feed to a boil box with an overall weir to the screen. A spreader plate was used to evenly distribute the screen feed. This concept had a number of variables simulated and it was found that the momentum of the feed was too high and induced a surge flow at the end of the collection box. There was also an uneven feed to the downpipes resulting in uneven particle distribution feed to the screen. Low velocities would also result in the particles settling and blocking the chambers. There was insufficient gravity head available to overcome the challenges of this type of design.

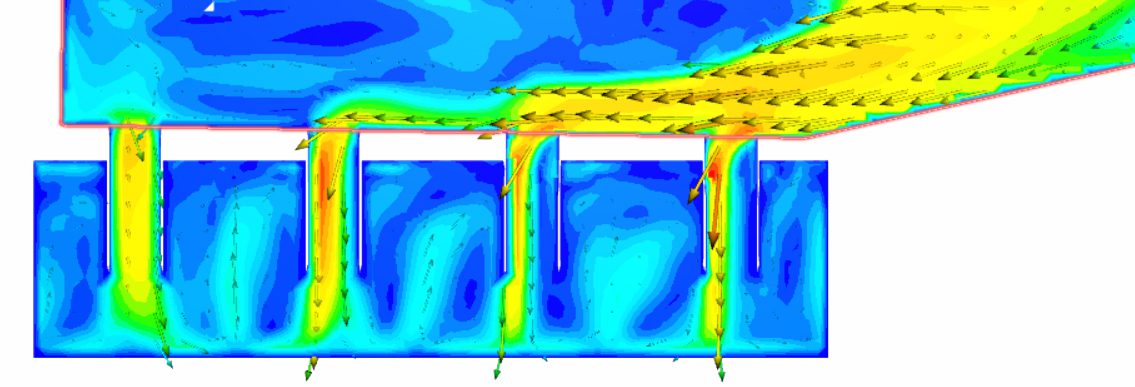

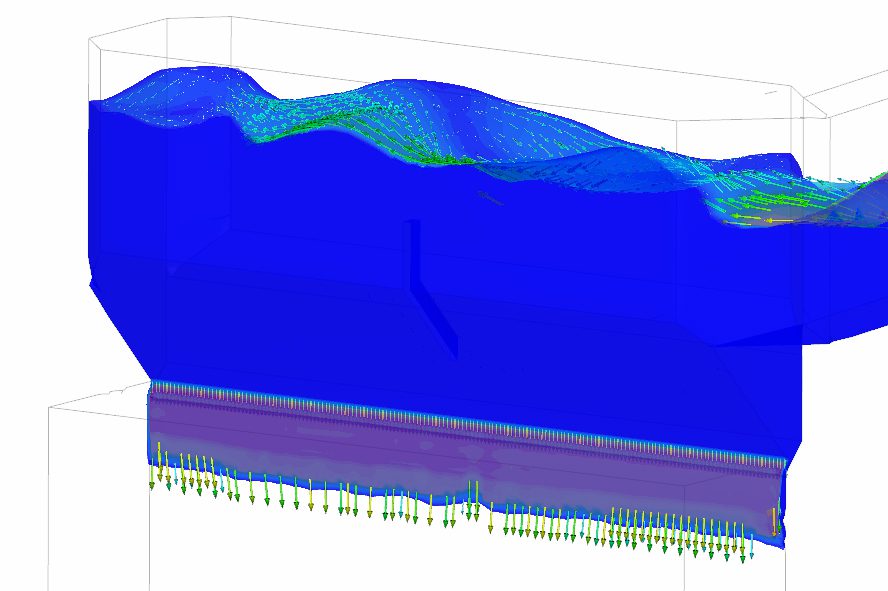

A single enlarged chamber feed box with an adjustable bottom slot for the screen feed was designed. The slot is used to reduce wear and improve screen feed direction. A single baffle is added to induce mixing and reduce wave surging. This arrangement reduces the gravity head requirements, allowing maximum flow velocity to be achieved upstream in the launder. It also eliminates particle settlement concerns. The lower overall velocities reduce wear on the launder lining and construction and an even screen feed is achieved.

If we think in terms of de-risking costly mining plant and equipment design in remote locations then the need for assurance at the design stage becomes critical. Previously we were using a local version of OPENFOAM and compared to SimScale we have saved hundreds of hours of training and simulation time – without compromising on accuracy.

Michael Jeffs

Senior Mechanical and Project Engineer (CEng IMechE)

Sign up for SimScale

and start simulating now