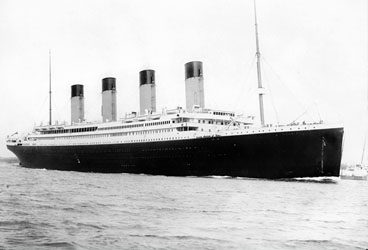

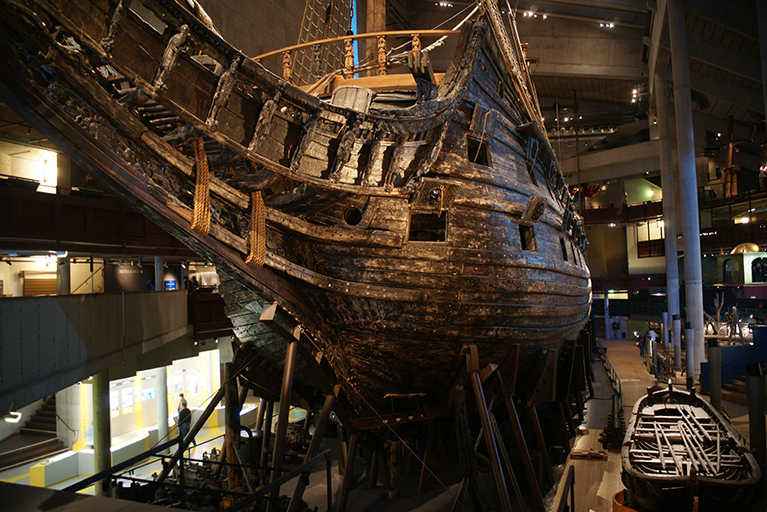

It was 4 p.m. on August 10th, 1628, and the Vasa ship had barely left the docks of Stockholm harbor on its maiden voyage. Only 1300 meters into its voyage, a light gust of wind toppled the ship over on its side. As water flooded through the gun portals of the ship, it sank in the shallow waters of Stockholm harbor and lay there at 32 meters deep, forgotten. In 1956, the Vasa ship was found by Anders Franzen, a Swedish marine technician and amateur naval archaeologist. It was salvaged between 1959-61 and can be found today in the museum that was specially built for it.

What happened on that fateful day of August 10th? Was it expected? Why did the Vasa ship sink? Let’s dive deeper into the heart of the mystery. Several videos analyzing the Vasa ship can be found on YouTube. Here is a particularly brief yet interesting one:

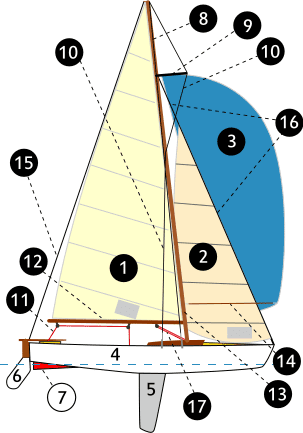

As we go ahead, we will need to understand the terminologies related to shipbuilding. Hence, defining some terms visually could be the best solution.

- Mainsail

- Staysail

- Spinnaker

- Hull

- Keel

- Rudder

- Skeg

- Spar

- Spreader

- Shroud (sailing)

- Sheet

- Boom

- Mast

- Spinnaker pole

- Backstay

- Forestay

- Boom vang

The Vasa Ship The Building of the Vasa Warship

We can never get the full story without first understanding the events that unfolded relating to the building of the ship and the historical time in which it was built. It was on the 16th of January, 1625, that King Gustav II Adolph of Sweden directed Admiral Fleming to sign a contract with the shipbuilders of Stockholm (Hendrik and Arend Hybertsson) to build four ships. Two smaller ships (108-ft keel length) and two bigger ships (135-ft keel length) were to be built over the course of four years. In the months that followed, King Gustav changed his orders several times, leading to total chaos and confusion for the builders.

The Swedish Navy lost ten ships on the 10th of September 1625, which led the king to order that the two smaller ships be built on an accelerated schedule to compensate for those they had lost. One can’t blame him, as those were the days when various parts of the world were colonized, and naval forces meant strength. These were meant to be two small ships (111-ft and 135-ft ships). Please note that the dimensions stated relate to the keel length unless explicitly specified otherwise.

On one front, the construction of the 111-ft ship with a single gun deck began. Simultaneously, on the other, the king received news that the Danish were building a ship with two gun decks. How did the king react to this one-upmanship? If you know anything about the egos of kings and dictators, you will have guessed it right. He immediately ordered Admiral Fleming to build a 135-ft ship with two gun decks. Until then, no one in Sweden had ever built a ship with two decks. This development from one- to two-deck warships marked a significant change in Naval architecture between 1600–1700.

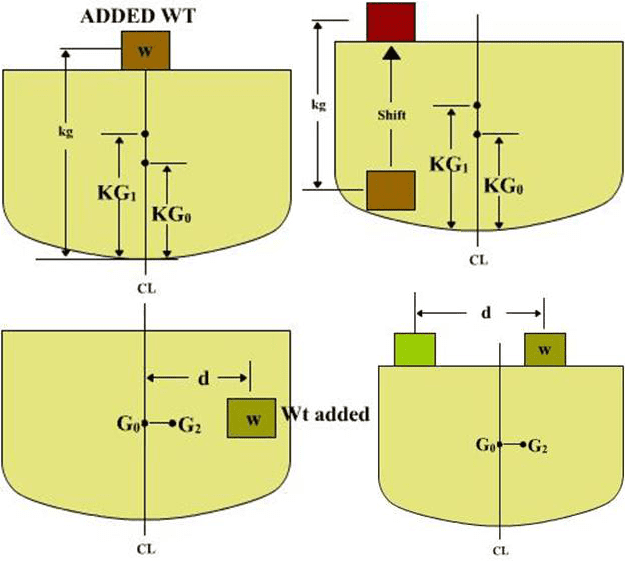

While the original Vasa was a traditional architecture that was commonly used in shipbuilding, it is believed that it is likely that no specifications, crude designs, or plans were made. Hybertsson was an experienced shipbuilder and would likely have taken it on as another standard, traditional job. However, once the circumstances changed, no modified plans were found for the larger, more complex version of the Vasa. Under time pressure, it is believed that Henrik Hybertsson just “scaled up” the dimensions of the original 108-ft ship to meet the length and breadth of the new 135-ft Vasa. Since this was totally unplanned, the width of the upper parts of the ship was wider than originally planned by one foot and five inches. At this point, the Vasa ship was becoming much wider at the top than the bottom. The ship’s center of gravity was much higher than designed.

At this point, you must already be sensing the impending disaster and wondering how everyone else failed to notice. Time can be a funny thing! The Vasa ship was a disaster waiting to happen. Additionally, it did not help that the primary designer, Henrik Hybertsson, fell ill and died in 1627, almost one year before the Vasa was completed.

The plans were undocumented, there were no detailed specifications, and five different teams were working on the hull without any intercommunication! This was one of the biggest projects in Sweden at that time, and it was a total disaster just waiting to happen.

Vasa Ship Was the Vasa Ship Tested?

While the Vasa ship already seemed unstable at the harbor, at this point in history, there were no known methods to measure the stability, center of gravity, or heeling (or toppling) characteristics. Most captains simply used trial and error to understand the best operational characteristics.

Admiral Fleming and Captain Hannson (Vasa’s captain) ran a test with 30 men running side-to-side (a “lurch” test). After three rounds by the men, the test was stopped at the ship rocked so violently that it was feared that it would heel. However, no one had any ideas to help stabilize the ship. While additional weight below the floorboard would have been one option, there was barely any floor space. In addition, the Vasa had 120 tons—almost twice what was needed to stabilize, and if any more were to be added, this would have sent the lower deck gun portals to the waterline of the ship.

Even knowing that the ship had stability issues, it was given the go-ahead, which was the result of three factors:

- Pressure from King Gustav,

- The king of Poland had started a war campaign, and;

- No one knew what else to do.

The Vasa Ship Disaster The Dreadful Day for Vasa

The Vasa ship was one of the costliest projects of the time, with hundreds of ornate, gilded, and painted carvings depicting biblical, mythical, and historical themes. It was meant to be the most impressive ship, and no cost was spared. However, all these extra features only further raised the ship’s center of gravity!

On the 11th of August 1628, the Vasa left Stockholm harbor. It barely made it two nautical miles when it was faced with a wind gust of eight knots. The wind was so light that the sails were extended by hand and just one person was sufficient to hold the sheets out. Even with such a light wind, the ship heeled (toppled) on its side, water filled the ship through its gun portals, and it eventually sank in the harbor, taking 53 lives with it. The captain of the ship survived the incident and was immediately jailed for incompetence. However, a formal hearing was conducted in September of the same year, and the captain and crew were set free, and the charges of incompetence were dropped. However, no exact reason was determined.

Vasa Ship Learning Restoration and Lessons from Vasa

The ship had sunk in the shallow waters of the Baltic sea, and due to the salinity of the water, the wooden vessel survived infestation and degradation. Exactly 333 years later, it was pulled up to the surface of the harbor. After the water and mud were pumped out, and the gun portals sealed, the Vasa ship floated. Today, it stands in a separate museum of its own—Vasa Museum.

The factors that contributed to the failure of the Vasa ship were plentiful but can be summarized in 4 main reasons:

1. Unreasonable time pressure

2. Changing specifications and lack of documentation or project plan

3. Over-engineering and innovation

4. Lack of scientific methods and reasoning

As evident, one of the primary scientific reasons can be attributed to a lack of stability due to the ship’s raised center of gravity. Without the existence of proper tools for the design and testing phase, building Europe’s mightiest warship and preventing foundering was even harder.

Explore FEA in SimScale

Three centuries later, we have access to all of these tools, but design mistakes are still being made. Engineering simulation software is not always integrated into the design process, mostly due to high costs and lack of specialized training. With the SimScale cloud-based platform, however, engineers working in shipbuilding and boat design can use CFD and FEA simulation via a standard web browser and from any computer. As for the training, there are hundreds of free learning materials available online. An on-demand webinar about multiphase flow is a good start. Just fill out this form and watch it for free.

References

- The Science Behind Saving A Sunken Ship – Conserving The Vasa Warship, Forbes

- Vasa (ship), Wikipedia

- Vasa Museum in Stockholm

- New Clues Emerge in Centuries-Old Swedish Shipwreck, PRI

- Failure Analysis of Vasa by Prof. Kenneth E Lulay

- The Bizarre Story of ‘Vasa,’ the Ship That Keeps On Giving, Smithsonian.com

- Why the Vasa is getting a makeover and losing weight, The Local

- Vasa, A Swedish Warship by Fredrick M Hocker