On April 14th, 1912, the R.M.S. Titanic was on its maiden voyage from Southampton, England to New York, United States when it collided with a massive iceberg. Of the 2,200 passengers and crew that were aboard, only 705 survived. Despite the builders’ claims that — even under the worst possible conditions at sea — she was unsinkable, it took less than three hours for the Titanic to sink. The ship’s builders even made claims that it should stay afloat for a minimum of 2-3 days if tragedy struck. So why did the Titanic sink? Was it the material failure or bigger design flaws that went unnoticed? Let us analyze why the Titanic sank from an engineer’s perspective.

First, on that note, National Geographic made an interesting CGI on how the Titanic sank:

At the time of her construction, the Titanic was the largest ship ever built. It was 230m long, 25 stories high, and weighed 46,000,000 kg. The ship’s turn-of-the-century design and technology included sixteen major watertight compartments in her lower section that could easily be sealed off in the event of a punctured hull and hence deemed her unsinkable.

On the night of April 14th, although the wireless operators had received several ice warnings from other ships in the area, the Titanic continued to rush through the darkness at nearly full steam. Unfortunately, by the time the lookouts spotted the massive iceberg, it was only less than a quarter of a mile off the bow (or front) of the ship, making the crash into the iceberg unavoidable.

Imagine trying to suddenly avoid a head-on collision in a car; that sounds hard, right? The Titanic was about 20,000 times heavier and had the full momentum of all that weight driving it forward. Though the engines were immediately thrown into reverse and the rudder turned hard left, slowing and turning took an incredible distance because of the tremendous weight (or mass) of the ship. Without enough distance to alter her course, the Titanic sideswiped the iceberg, damaging nearly 100 meters of the right side of the hull above and below the waterline [1].

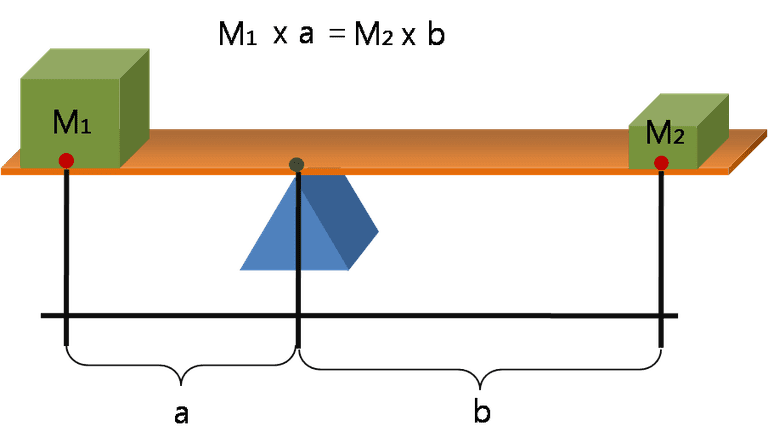

The massive side impact caused enough damage to allow water to flood into six of the sixteen major watertight compartments. As water rushed into the starboard side of the ship’s bow, the ship began to tilt down in front and slightly to the right. However, the back (or stern) of the ship had three large and heavy propellers. Just like a lever, as shown in Figure 2, if the board is not strong enough when one side becomes extremely heavy, and the other end is pushed down—the board breaks.

This is almost exactly what happened on the Titanic, too. The front of the ship started to go into the water, leading to the lifting of the stern of the ship out of it. When the ship was almost at 45 degrees, the stresses in the ship’s midsection increased beyond the material limits of steel (210 MPa). The Titanic almost split wide open in the middle! This is how the Titanic sank. [1]

Discover the benefits of cloud-based CFD simulation with SimScale, in this features overview download.

Exploring the Titanic Why Did the Titanic Sink?

While we have had a glimpse as to what caused the ship to start sinking, was that the only reason? What are the scientific theories that have emerged on why the Titanic sank?

One of the first major scientific insights into the sinking of the Titanic was obtained after a 1991 expedition, called the Imax, to the Titanic wreck. This expedition and the research that followed opened numerous discussions that led to the uncovering of clues on why the Titanic sank. Surprisingly, one of the major discoveries of this expedition included chunks of metal that were once a part of the Titanic’s hull. These Frisbee-sized pieces of steel were about one inch thick with three rivet holes, each one 1.25 inches in diameter [1].

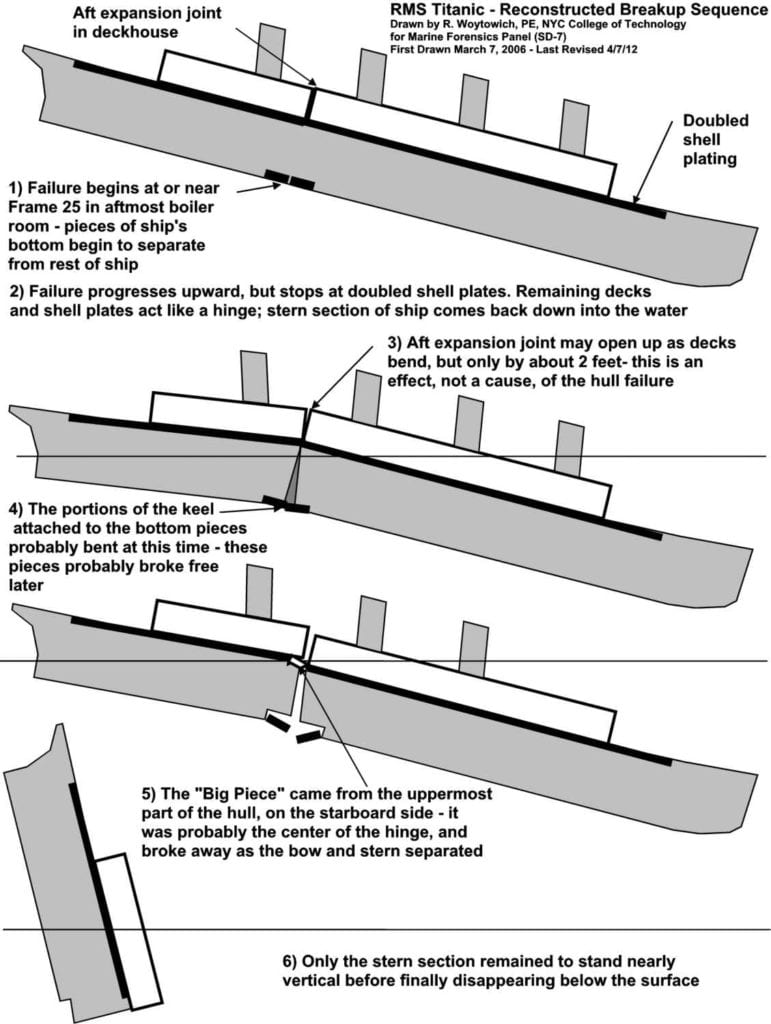

So why did the Titanic sink? As shown in Figure 3, the ship is believed to have sunk due to multiple contributing factors.

Titanic Analysis Evidence and Analysis of Why the Titanic Sank

Failure Due to Impact on Hull

One of the key pieces in reconstructing the theory of why the Titanic sank included the pieces of steel that were recovered. Let’s see how some pieces of steel helped answer the question “Why did the Titanic sink?”

Most engineers would have done uniaxial tests during their laboratory sessions. Here a specimen, shaped like a dog bone, is pulled to understand how the material changes shape (or deforms) for the applied load. This is continued until the specimen breaks into two pieces. While materials like aluminum undergo ductile fracture, others like cast iron show no yielding and are brittle. For more information on the brittle-ductile–yield criterion, please read the article “What is the meaning of von Mises stress and yield condition?”

In spite of the captain of the ship trying his best to slow down, the huge mass and momentum meant that the Titanic was still moving at a powerful speed when it impacted the iceberg. This high-speed impact was the start of the disaster. When the Titanic collided with the iceberg, the hull steel and wrought iron rivets failed, due to “brittle fracture”.

Most often, for many commonly used structural materials, impact at extremely high speeds results in brittle fracture without any yielding (or plastic deformation). This is a type of catastrophic failure in structural materials, the causes of which include low temperature, high-impact loading, and high sulfur content.

You guessed it right! On the night of the Titanic disaster, all three factors were present. The water temperature was below freezing, the Titanic was traveling at a high speed on impact with the iceberg, and the hull steel contained high levels of sulfur. It is here where the chunk of iron discovered during the expedition played a major role in providing the hint that the brittle fracture of the hull steel contributed to the disaster. The condition of the edges of the recovered piece of steel was noted to be jagged, almost shattered (like broken china), and sharp upon cleaning it. This brittle fracture of hull steel is probably what the survivors of the disaster then described as a loud noise that sounded like breaking china. Today, typical high-quality ship steel is more ductile and deforms rather than breaks [1]. Astonishingly, scientists discovered that the metal pieces showed no evidence of bending or deformation, they simply shattered! This is one of the main answers to the question “Why did the Titanic sink?”

Laboratory Testing of Hull Materials

In order to confirm this hypothesis on why the Titanic sank, scientists subjected a cigarette-sized specimen/coupon from the pieces to the Charpy test. This is a highly popular test to measure the brittleness of a material. It is run by holding the specimen against a steel backing and striking it with a 30-kg pendulum with a 0.75-meter-long arm. The pendulum’s point of contact is instrumented, with a readout of forces electronically recorded in millisecond detail.

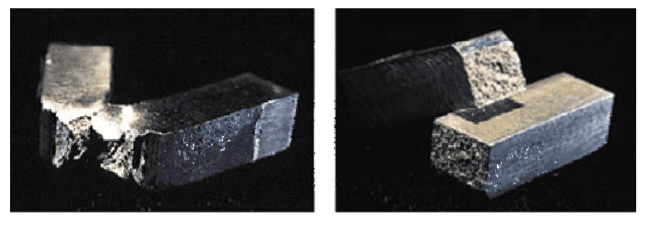

A piece of modern, high-quality steel was tested along with the coupon from the hull steel. Both coupons were placed in a bath of alcohol at -1°C to simulate the conditions on the night of the Titanic disaster. When the coupon of the modern steel was tested, the pendulum swung down and halted with a thud; the test piece had bent into a “V”. However, when the coupon of the Titanic steel was tested, the pendulum struck the coupon with a sharp “ping”, barely slowed, and continued upon its swing; the sample, broken into two pieces, sailed across the room [1].

The pictures above show the two coupons following the Charpy test confirming the brittleness of the Titanic’s hull steel. When the Titanic struck the iceberg, the hull plates did not deform, as they should have. Instead, they fractured! This leaves us wondering if the designers anticipated this fracture, and it contributes to the reasons why the Titanic sank.

Did Chemistry Have an Effect?

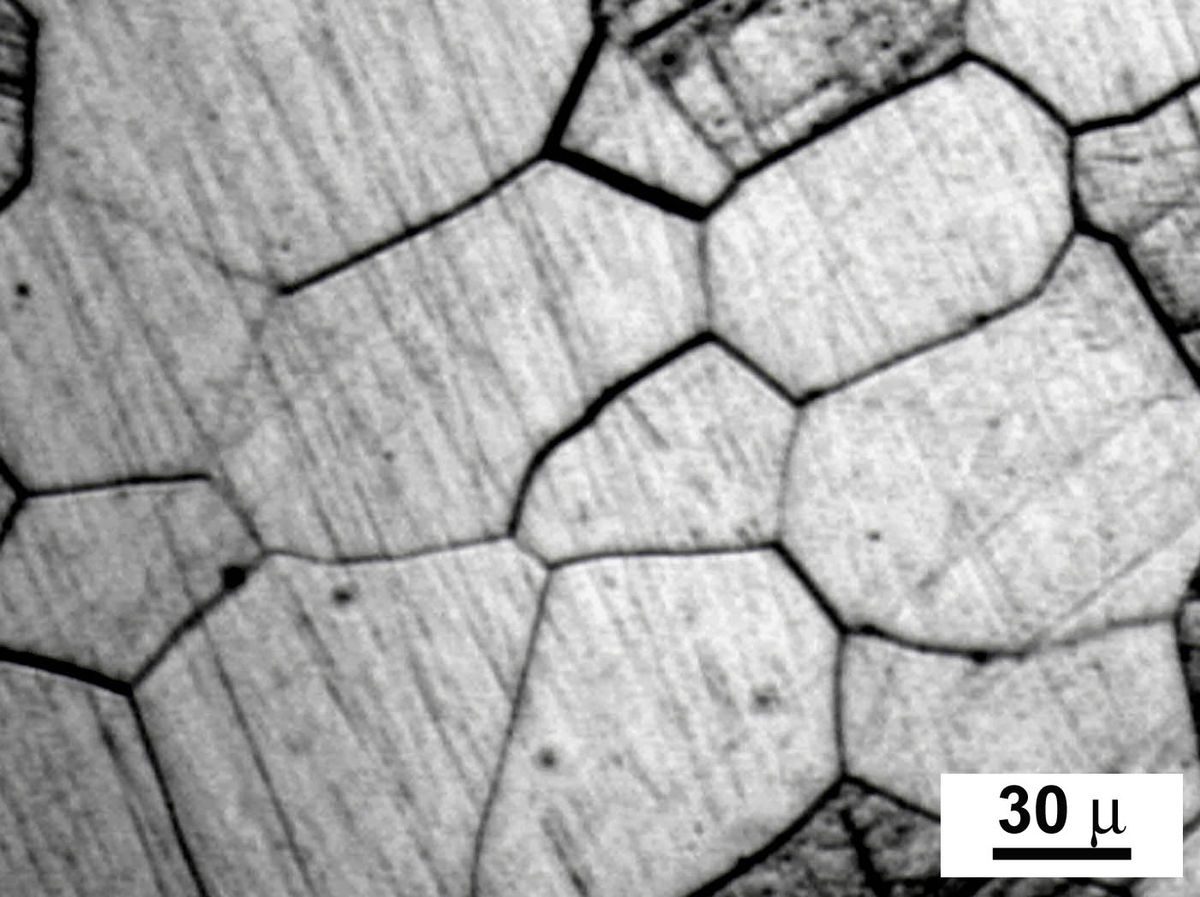

In the search for answers to the question “Why did the Titanic sink?”, the steel from the Titanic was further analyzed for chemical components and was found to contain high levels of both oxygen and sulfur, which implied that the steel was semi-kilned, low-carbon steel, made using the open-hearth process. If one had a powerful microscope to zoom in on the dimensions of order or micrometers, you would see that steel shows a grain structure, as shown in Figure 5.

High sulfur content disrupts the grain structure of steel, leading to an increase in its brittleness. When sulfur combines with magnesium in the steel, it forms stringers of magnesium sulfide which act as “highways” for crack propagation. Although most of the steel used for shipbuilding in the early 1900s had a relatively high sulfur content, the Titanic’s steel was particularly high, even for those times [3].

While the material is normally quite ductile, the addition of oxygen causes the material to transition from ductile to brittle in nature. This proved the plausibility of brittle fracture of the hull steel. It is a known fact that high oxygen content in steel leads to an increased ductile-to-brittle transition temperature, which was determined as 25°C to 35°C for the Titanic steel. Most modern steels would need to be chilled below -60°C before they exhibited similar behavior.

Further Design Flaws

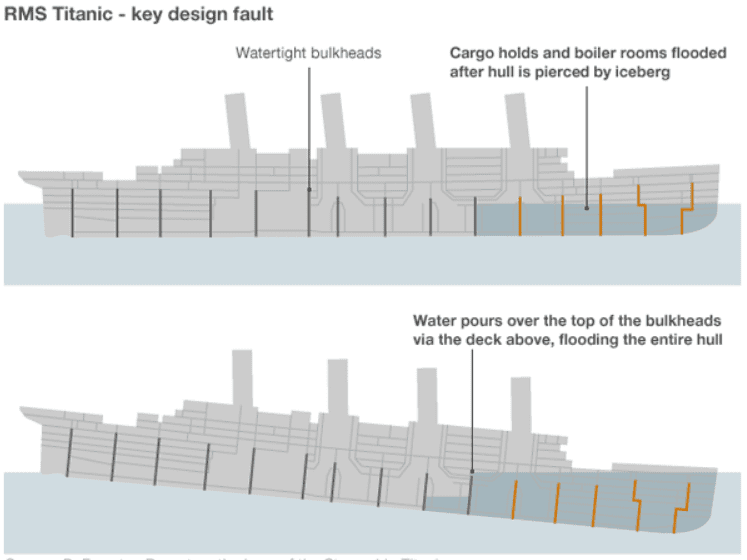

Material flaws were not the only factors that led to the sinking of the Titanic and hence are not the complete answer to the question “Why did the Titanic sink?” The design of the ship was not nearly good enough to deem it an unsinkable ship. The watertight compartments in the ship’s lower section were not exactly watertight, in any sense. The lower section of the Titanic was divided into sixteen major watertight compartments that could easily be sealed off if part of the hull was punctured and leaking water. These watertight compartments, which made the ship designers claim that the ship was unsinkable, were only watertight horizontally.

The tops of these compartments were open, and the walls extended only a few feet above the waterline [3]. In order to contain water within the damaged compartments, it was imperative that the walls of the watertight compartments positioned across the width of the ship be a few feet taller. Although this is not the reason why the Titanic sank, without this design flaw it would have slowed down the sinking process, possibly allowing enough time for nearby ships to help.

The collision with the iceberg damaged the hull portion of six of these sixteen compartments, and the compartments were immediately sealed. But as the water filled these compartments, the ship began to pitch forward from the weight of the water in this area of the ship, and the compartments began to spill over into adjacent compartments due to the horizontal watertight nature. The bow compartments were extensively flooded, and subsequently, the entire ship was flooded, causing the Titanic to be rapidly pulled below the waterline.

The watertight compartments, rather than countering the damage done by the collision with the iceberg, contributed towards accelerating the disaster by keeping the flood waters in the bow of the ship. Without the compartments, the Titanic would have remained horizontal as the incoming water would have spread out. Eventually, even in this case, the ship would have sunk, but she would have remained afloat for a few more hours before capsizing [1]. Scientists maintain that this amount of time would have been sufficient for nearby ships to reach the Titanic’s location and all of her passengers and crew could have been saved.

What Could Have Been Done Better?

The Titanic disaster serves as a perfect example of how engineering flaws can have catastrophic effects. Analyzing the answers to the question “Why did the Titanic sink” takes us to the conclusion that had the design of the ship and the materials chosen been better, the disaster could have been easily warded off.

If the ship had double bottoms, constructed by taking two layers of steel that span the length of the ship and separating them by five feet of space, extending up the sides of the hull, the bottom plate of the hull would have been punctured without damage incurred to the top plate. With a double bottom, the chance that a punctured hull would allow water into the watertight compartments is minimized.

By extending the double bottoms up the sides of the hull, the watertight compartments could remain undamaged. The addition of a layer of steel to the sides of the ship ensures that in the event of an iceberg or a collision with another ship, only the space between the inner and outer sidewalls would flood with water, barely puncturing the hull. Also, if the transverse bulkheads of the watertight compartments were raised, the spilling of water over the tops of the bulkheads into adjacent, undamaged compartments could have been avoided, as the ship pitched forward under the weight of the water in the bow compartments.

Here it is, an engineer’s analysis of why the Titanic sank. Although it is important to understand the errors of the past, it is crucial to make sure they are not repeated in the future. A proper design process can prevent such catastrophes.

If you’d like to read more on this topic, here are other articles that also talk about why the Titanic sank:

- Why did the Titanic sink? by Science Illustrated

- The secret of how the Titanic sank by US News

There are many more out there that answer the question “Why did the Titanic sink?”

Explore FEA in SimScale

Using Modern Tools of FEA and CFD for Ship Design

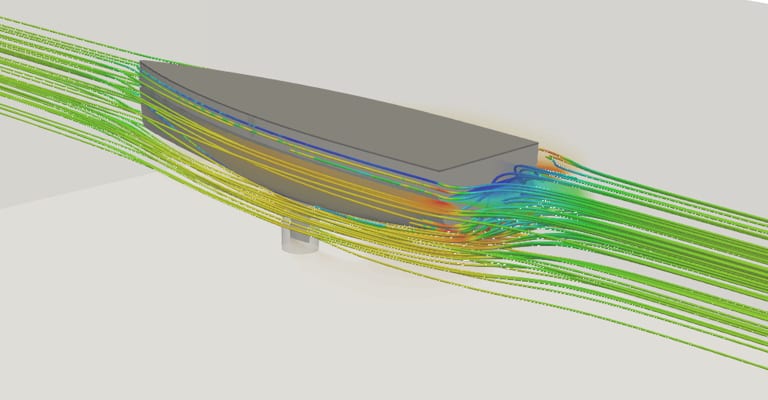

Today, with advanced tools at hand, you can use CFD and FEA simulations to virtually test a ship’s design to make sure such catastrophes don’t happen in the future.

If you want to explore further the reasons why the Titanic sank, you can use the SimScale cloud-based simulation platform to analyze the stresses on the ship’s hull due to the water, for example. This CAD model of the Titanic is already uploaded to the platform and you can just copy the project and set up a simulation. To discover all the features provided by the SimScale cloud-based simulation platform, download this overview.

To learn how to run simulations with SimScale, you can watch the recording of the first session of the CFD Master Class. Just fill out this short form, and it will play automatically.

References

- Gannon, Robert, (February 1995). “What Really Sank the Titanic.” Popular Science, 246(2), pp. 49-55

- Woytowich, Richard, (April 2012). “Titanic Sinking Tied to Engineering, Structural Failures”. Retrieved from https://www.huffingtonpost.in/entry/titanic-sunk-new-theory_n_1412622

- Hill, Steve. The Mystery of the Titanic: A Case of Brittle Fracture? Materials World, 4(6), pp. 334-335