Formula SAE is a student design competition created by SAE International. The aim of this competition is to give to the participants the chance to experience working in a motorsport team. They have to design, manufacture, test and drive a Formula-style race car, all while respecting the different rules established by Formula SAE. There are events all around the world where students from universities of every country can compete on different aspects, such as speed, design, cost, and more.

Fuel Tank Design Fuel Tank Design in Formula SAE and Motorsport

One of the main problems identified as needing research and development in motorsport is the design of a fuel tank. This issue is also very important in Formula SAE, as the fuel tank is a core part of the car and needs to be absolutely secure, with no leaks and with the lowest possible weight. To reduce weight, each team has to study the consumption of its car and design the fuel tank to hold an optimal amount of fuel to finish the Endurance (the longest event of the competition).

At the end of the race, car handling changes massively because most of the fuel is already consumed and the tank is nearly empty. This result is a phenomenon called sloshing, which means that the fuel is pulled by inertia forces towards the corners of the fuel cell. This is a massive problem because the engine can stop if it doesn’t receive fuel soon and it can provoke the retirement of the team.

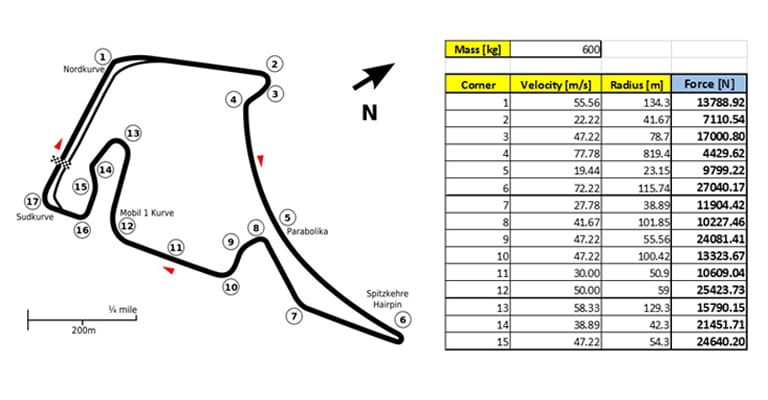

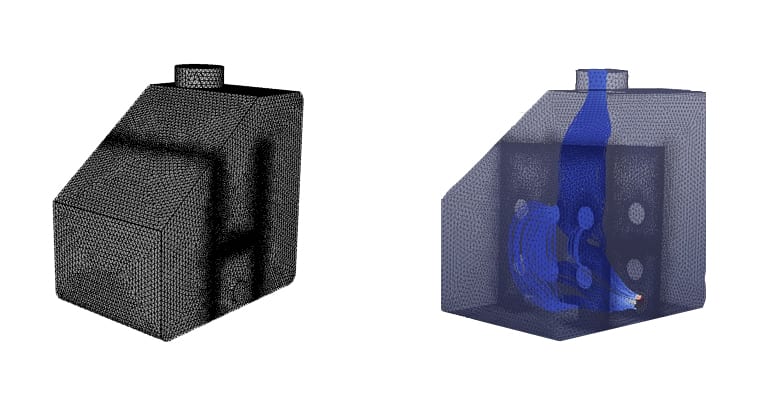

Computational fluid dynamics can be used to avoid this problem. It is possible to simulate several designs of fuel tanks to analyze the behavior of fuel inside it and study if the circuit where we are going to compete will provoke that effect. For that, it is necessary to conduct an in-depth study of the circuit, analyzing forces on corners and preparing a sequence of them.

This requires a huge effort because it is necessary to estimate the velocity on each corner (analyzing, if it’s possible, other years’ performances) and calculate for each corner the force over the Formula SAE car. This task is critical because it will be the base of the simulation. A file will be created with all the important parameters, which will be the boundary conditions of our simulation.

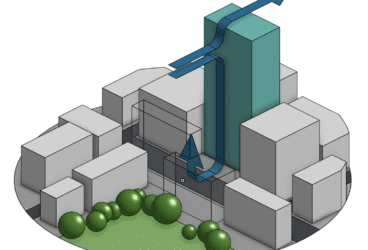

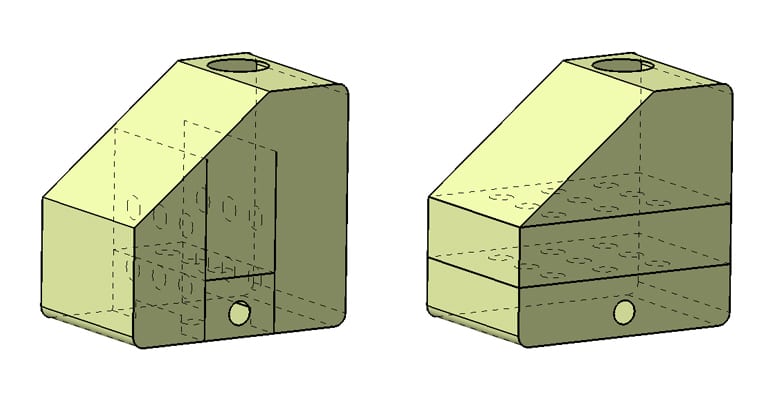

The next step is to create several designs of the fuel tank, adapting it to the shape of the car and taking into account the other components of the engine. On any motorsport car, there is very little space, and a Formula SAE car is no exception—so it’s essential to design the different components as a block to be able to introduce and manipulate every part.

As we have seen, fuel moves from one side of the fuel tank to the other, while the pilot is driving, so it’s necessary to find some solutions to stabilize it and ensure that the injection valve always has fuel. The most common solution is to introduce some breakwaters in the fuel tank which prevent fuel to “dance” from one side to the other. For this project, we designed several types of breakwaters to analyze through CFD analyses.

Fuel Tank Design Conclusion

Based on the simulation results, we were able to identify the best design for the circuit of the competition (Hockenheim in this case), and we developed a test fuel tank to prove it. Tests showed that without breakwaters, the fuel took five seconds to be stabilized. In contrast, it only took one second with breakwaters.

Finally, the design was developed, and the fuel tank was manufactured using aramid (essential to ensure that the fuel tank will not burn).

This method is used in all motorsport competitions, even the most elitist one—the Formula One—where teams use this kind of simulation method to develop their cars. The teams design the fuel tank and oil sump with this technique to avoid problems like lack of lubrication on the engine. For those cases, they simulate the forces over the car at Eau Rouge—the most difficult corner of the World Championship—because there are huge G-forces combined with altitude changes.

If you’d like to set up your own simulations, SimScale provides the possibility to carry them out in the web browser. To learn more, you can watch this webinar recording on how to optimize Formula SAE designs.