Test, confirm results, and optimize designs iteratively and easily in a cloud-based platform

In the pharmaceutical industry, mixing is absolutely necessary to ensure a homogenous, precise, and consistent product. Selecting the correct pharmaceutical equipment for your application depends on what is being mixed. This comes down to the properties of the substance including, among other things, viscosity, particle size, miscibility, texture, and chemical formula. Whether selecting an existing pharmaceutical mixer or designing new kind of blending equipment, testing should occur to ensure a consistent product with minimal batch times and energy use. This is where computational fluid dynamics (CFD) can offer support.

Pharmaceutical mixing equipment is required in the production of substances such as:

In such a highly-regulated industry, you need equipment that you can rely on to produce pure, safe, and effective substances. Using CAE capabilities, an engineer can easily assess the performance, efficiency, and effectiveness of a pharmaceutical mixer design. CFD offers clear insights into fluid mixing, flow patterns, and more to help you identify whether your mixing equipment will produce the product you need to adhere to regulations.

However, the high cost of hardware and steep learning curves of traditional, on-premises tools leave many designers to feel that simulation is not an option. SimScale has eliminated such traditional hurdles, thanks to the power of the cloud. With SimScale, engineers can:

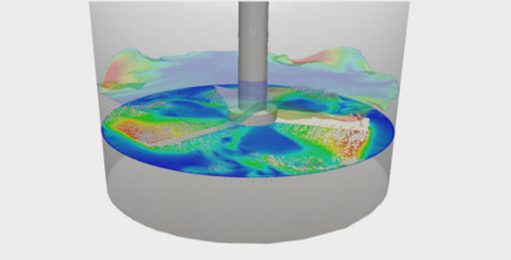

In pharmaceutical mixing equipment, the mixing ability needs to be consistent in all areas. In this project, you can see how transient simulation can be used to analyze the flow patterns and effectiveness of a mixing tank.

Sign up for SimScale

and start simulating now