Nowadays, many lighting technologies are available to the end-user. They range from the original, inefficient incandescent bulb to the latest and greatest customizable light-emitting diode (LED). Of course, there are many pros and cons for each type of technology and each design application. They include input power/luminous power ratio, cost, operating lifetime, luminous power depreciation, safety, maintenance, etc.

LED technology is a primary choice when users are concerned with energy consumption, controlled wavelength, and operating life. The latter is indeed a great advantage for LEDs in comparison to other technologies, with operating life sometimes exceeding 50K hours. Unfortunately, this tremendous advantage comes with a caveat; the light output of any LED decreases over time and may, after a certain time, reach a level outside of the required standards and its own original design specification.

Moreover, the emitted wavelength also shifts over time. This phenomenon also brings the device within the realm of unacceptable conditions in regards to appearance, efficacy, and color spectrum emission. Together, these two time-shifting quantities are important metrics when it comes to defining the performance of an LED device. The standardization of the measurement methods for these quantities is therefore a necessity for the entire lighting industry. The most common standards used today are LM-80-15 and TM-21.

Industry Lighting Standards: LM-80 and TM-21

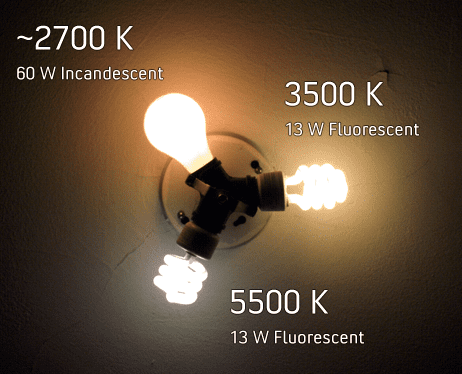

The Illuminating Engineering Society of North America Testing Procedures Committee (IES TPC) developed the IES LM-80 standard. This lighting standard describes the measurement methodology for two key LED performance metrics. The LED light output, also known as the luminous flux, and the chromaticity, or correlated color temperature (CCT). Correlated color temperature is essentially a scale of how cool or how warm the light emitted appears. This scale, in Kelvin, ranges from about 1000K (very warm) to 12 000K (very cold). Below is an example of different sources of commonly used lights and their measured correlated color temperatures.

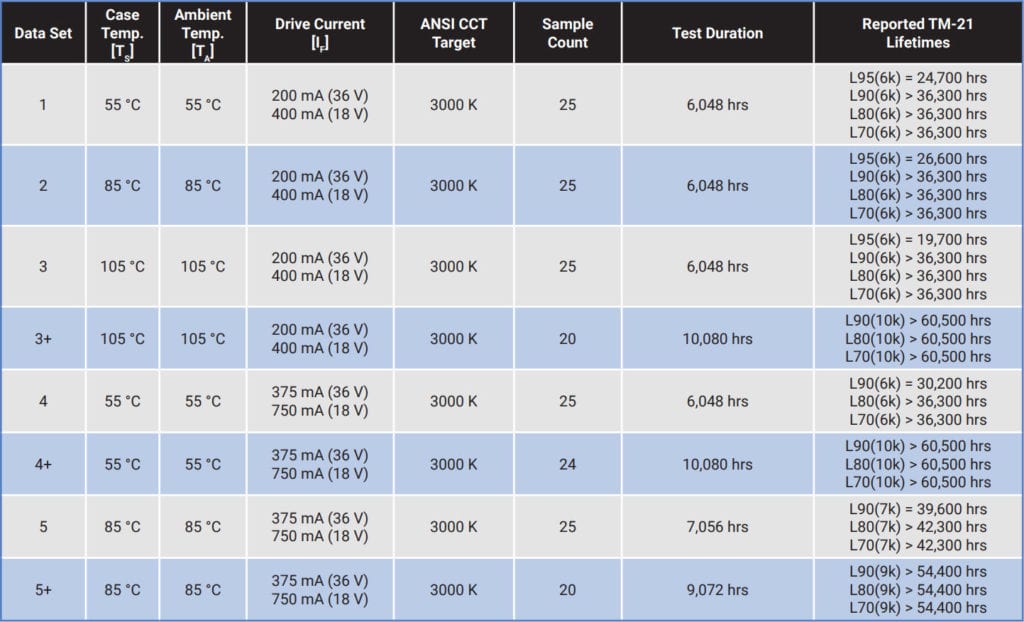

The LM-80 method focuses on testing procedures that include conditions, operations, and data collection methodologies. Like with any standard, the goal is to provide a reliable comparison framework of LED performance with devices produced by various manufacturers and tested in various laboratories. The latest version of IES LM-80 (2015) defines a test duration of 6K hours in order to collect enough data points for acceptable data extrapolation.

Once the LM80 testing has concluded, the measurements are then used to determine a depreciation curve for the luminous flux. The data is extrapolated using the method described in the Technical Memorandum TM21 to determine the “Lumen Maintenance Life Projection (Lp)”. The endpoint of the extrapolation is typically 70% of the initial light output, noted L70.

Since 2008, the IES TPC has developed a series of “paired” documents for testing and projecting luminous flux for component level (LED packages, modules, remote phosphors, etc.) and final product level (LED lamps, engines, and luminaires). These paired documents include IES LM-80 and IES TM-21; IES LM-84 and IES TM-28; and IES LM-86 and IES TM-29. To learn more about these, check out this presentation.

There are factors that must be considered when designing integrated LED fixtures, packages, or modules alone. In the fixture’s application and operating environment, the design of the fixture is critical, from the drivers and optics to the overall thermal management.

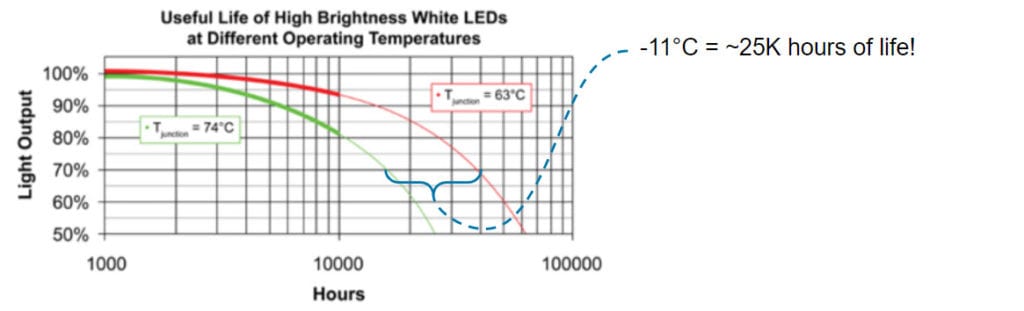

The latter is often considered to be the number one challenge when it comes to designing a device that will perform to an acceptable or exceptional LED light output level for a required lifetime. Indeed the rate at which the LED light output decreases over time depends highly on the temperature at which the LED chip is maintained. More specifically, it is the junction temperature between the die (the part that emits light) and the rest of the chip that is usually recorded as it is the warmest of all parts of the device. The higher the chip temperature, the faster the LED light output will decrease. The graph below, from the light research center, shows such a trend. On top of this, the difference in operating lifetime has been extracted from the curves.

(Source: Lighting research center)

The example graph above shows that a decrease of 11°C on the LED temperature means that the operating lifetime is prolonged by 25K hours!

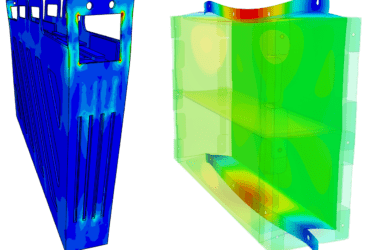

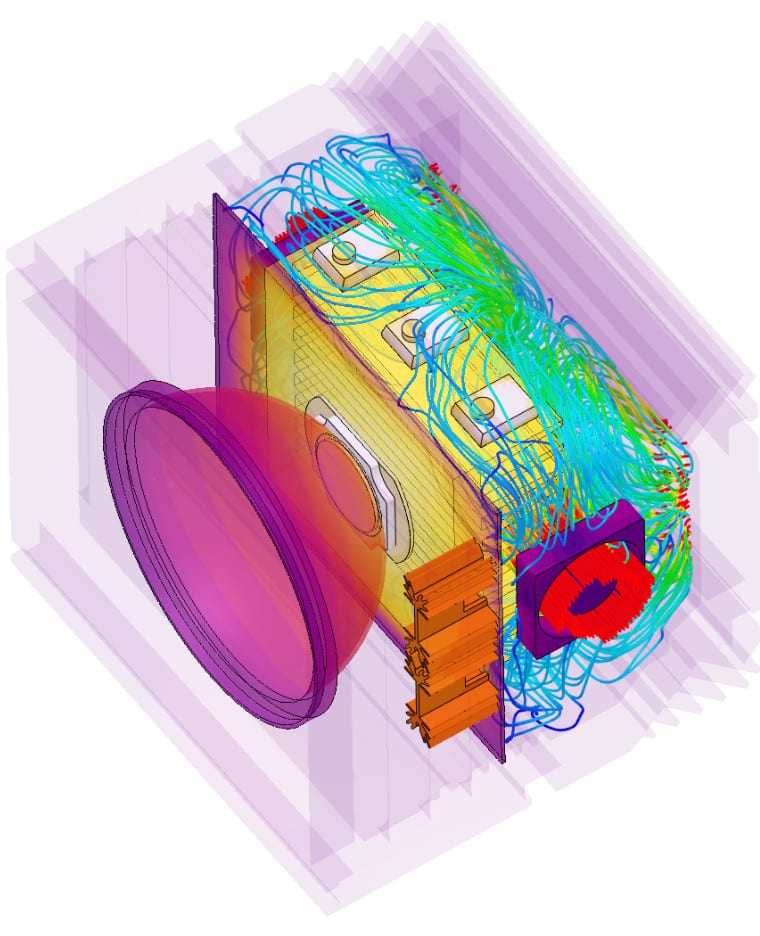

In this context, computational fluid dynamics (CFD) helps the designer to numerically test and predict the temperature of the LED and its fixture, to determine the best LED cooling technique. Such thermal performance testing occurs way before a prototype is built and the LM-80 (Lumen Depreciation of a LED Chip) test is carried out.

The temperature of the LED is directly dependent on the heat dissipation of the whole LED device, therefore the thermal performance aspect is of prime importance during the design process. The second part of this article focuses on how design engineers can use CFD in the cloud to numerically test their LED device design and predict such thermal performance.

Evaluating the Thermal Performance of Lighting Solutions in the Cloud

Testing the thermal performance of an LED device through CFD simulation is a fairly straightforward process. Whether the device is to employ LED cooling through active or passive cooling, the main objective stays the same; ensuring that the LEDs are kept below the maximum temperature recommended by the manufacturer and identify, if needed, areas of improvement in order to lower the temperature further.

The CFD simulation produces both quantitative (the temperature reached by each of the components for instance) and qualitative (distribution of the temperatures, hotspots, and recirculation of surrounding air) results. These types of results enable the engineer to make better, informed decisions on what to improve in their design.

While heat is transferred through multiple mechanisms; conduction, convection, and thermal radiation, there are many ways for the design engineer to improve their design. For the conduction of heat through the material, choosing a more conductive material or grade of material can significantly help the dissipation of the heat away from the LEDs generating heat. The thermal conductivity of the printed circuit board (PCB) on which the LEDs are typically mounted has a significant impact on the heat dissipation of the whole device. It is also one of the lower conducting parts due to the dielectric layers and orthotropic/direction-dependent material properties. This part of the webinar delivered on thermal performance analysis of lighting devices provides such an example.

Designers can also look at decreasing the thermal transfer resistance between the heat sink and the ambient air by altering the heat sink geometry and more specifically the fins or pins. Increasing the overall surface area in contact with the surrounding flow is a common way to decrease this thermal transfer resistance. Lastly, the resistance can be further reduced by improving the radiative properties of the heat sink, by using darker colors and surface treatment like anodizing or powdering. All of these angles of attack are possible ways for the design engineer to ensure their lighting device operates under acceptable conditions.

Conclusion

Design engineers can use CFD simulation to test multiple design variations simultaneously, within a few hours or even minutes, thanks to the power of the cloud. The results bring valuable insights about the heat dissipation that can be expected from the design, and specifically the temperature of the LEDs. Such insights constitute a reliable and accurate source for making informed decisions and choose the right design for the job and the budget.

The IES standards LM-80 and TM-21 set an industry-recognized method for measuring the light output depreciation over time and calculates the operating lifetime of an LED device. Such light output depreciation rate depends to a significant extent on the temperature at which the LEDs are maintained.

More information about SimScale’s lighting design evaluation and improvement capabilities can be found in this webinar.

Additional References to Learn More About LED Cooling and Thermal Performance:

- https://www.ledsmagazine.com/leds-ssl-design/packaged-leds/article/16695947/illuminating-engineering-society-updates-led-testing-standards-magazine

- https://www.ies.org/lda/maintenance-just-as-important-for-leds/

- https://www.penglight.com/lm80-lm79-l70-and-tm21-what-are-the-differences-for-lighting/