As the possibilities offered to us by technological advances grow larger, our electronic devices continue to shrink in size. Increased performance requirements and functionalities in a smaller space generate more unwanted heat within the casing of electronic equipment. Now, more than ever, engineers are faced with a pressing need to develop effective thermal management solutions early in the design process.

What is Thermal Management for Electronics?

There is much debate over the best strategies for managing thermal conditions of electronics but the question most often overlooked is: Why do electronics need cooling in the first place? The second law of thermodynamics dictates that energy usage results in waste heat. In electronic devices, an electric control current causes transistors to switch on and off or amplify electronic signals.

Modern processors can contain millions of transistors, meaning the additional current needed to power these transistors generates additional heat. Most electronic circuits also contain resistors that work to control the flow of the current to certain components. The energy resisted by these parts is converted into heat and adds to the thermal energy present within an enclosure.

Overheating within an electronic device can result, at its worst, result in the melting of components. Most often, however, electrical engineers are not able to see immediate damage or failure but, rather, products experience degradation over time. This is why accounting for effective thermal management solutions, early in the design process, is critical for performance. For example, in LED chips a difference of only a few degrees cooler can result in thousands of extended hours of product life.

With adequate heat management becoming a central issue in product development it is important to revisit the misconceptions that remain from earlier eras of electronics design. These are the 4 biggest myths we see in electronics cooling today and how engineers can counteract these mistakes with the best tools for the job.

Myth One: Adding Extra Heat Sinks or Fans Can Fix Any Problem

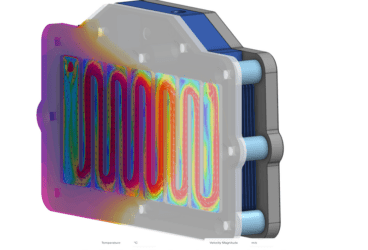

As heat needs to be dissipated or moved away from sensitive electronic components, thermal interface material is used to conduct thermal energy to components like heat sinks. Heat sinks work by dissipating heat into the surrounding air and fans increase the airflow to support this heat loss mechanism, so one might be inclined to believe that simply adding more will equate to improved thermal management.

However, engineers designing devices that are increasingly smarter, and smaller, understand that there is always a tradeoff between space, cost, and energy consumption. By installing an additional component, space on the board is occupied, energy demand is increased and overall production cost goes up. With the installation of additional parts to a circuit, the probability of failure increases, as well.

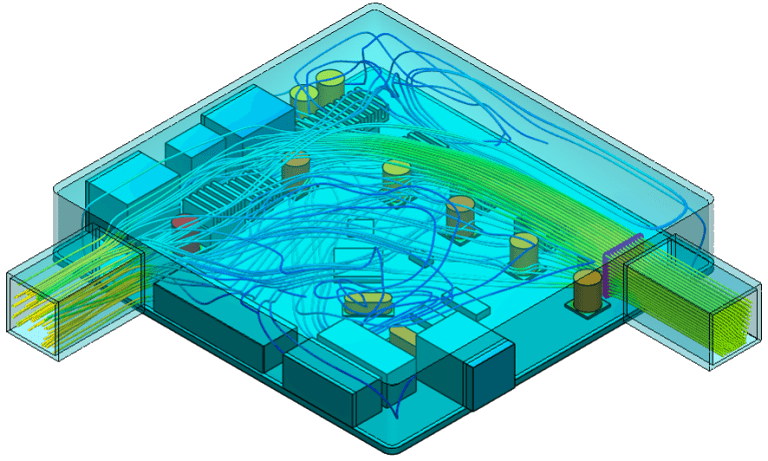

These considerations show that the answer to smarter, better, and more cost-effective thermal management lies not in additional parts but in early-stage design optimization. Simulation is an accurate tool that allows teams of designers to identify problems before incurring the cost associated with traditional physical prototyping. Forwiz System used simulation to test and validate CPU cooler design for optimal cooling performance.

Myth Two: Tools for Thermal Management Have Not Evolved

As mentioned previously, the rules that dictate the need for electronics cooling are universal laws that have been recognized for centuries. And, similarly, the mathematical problems created by waste heat can be solved by equations that already exist. But it is incorrect to believe that because the mathematical theories have not changed, neither have the tools used for heat design.

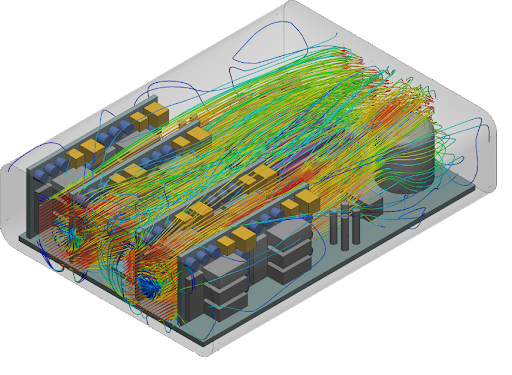

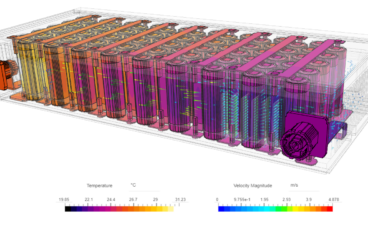

For example, computational fluid dynamics can be used for early-stage simulation of heat management in electronics. This type of simulation uses the Navier-Stokes equation which was first developed in 1821 and has been used since the first thermal CFD software was released in the 1990s.

Despite this, modern tools allow engineers to unleash simulation in their design process without needing to understand complex mathematical equations in great detail. Setting up simulation no longer necessitates complex equations for all physical variables and laborious mesh tweakers.

CFD software today allows engineers to orient their simulation around real, physical problems like open boundaries for natural convection supplemented by smart default values. And, tools used in thermal management designs have advanced by continuously updating the capabilities of their solvers.

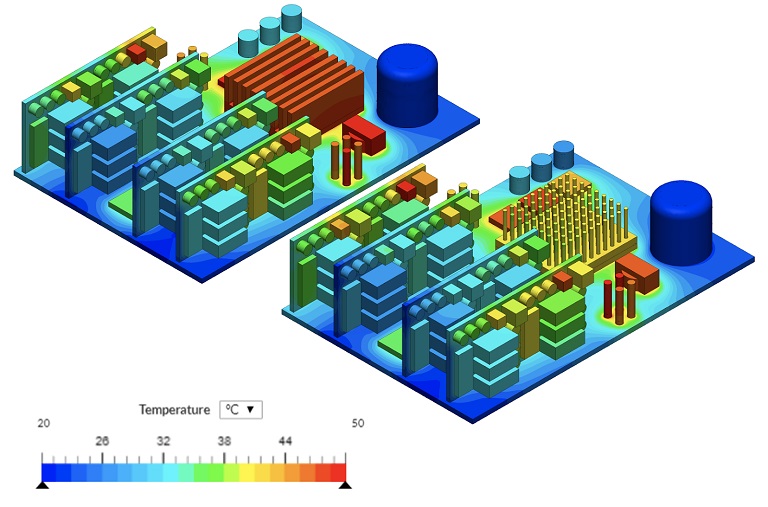

SimScale’s Conjugate Heat Transfer v2.0 improves on the original algorithm and now calculates the temperature field through all regions at once in a fully coupled manner, no matter how many solid components and flow volumes or cavities one has. This speeds up convergence and allows for a more efficient parallel computation, which provides engineers with more accurate results, faster.

Myth Three: Simulation Is Only for Experts

It is clear that thermal management design benefits greatly from simulation, however, many may still believe that it is a practice reserved only for those specially trained in modeling and simulation. Cloud-based tools, like SimScale, reduce the barrier to access for engineers allowing powerful, high-fidelity simulations to be performed with nothing more than an internet connection and web browser.

Integrated plug-ins allow users to model their CAD in OnShape and directly import model iterations seamlessly into the same project within the SimScale workbench. For thermal engineers, this can mean testing different component placements or heat sink and fan orientations and evaluating their effect on thermal performance. They can also test multiple variations of heat sink material or designs, different fans, and casing designs, and optimize convective flow behavior. SimScale enables designers to run multiple simulations in parallel, offloading the high-performance computing power to the cloud, so users’ machines are freed up for other operations.

Myth Four: Simulation Tools Are Expensive

Simulation tools that utilize cloud computing do away with much of the costs associated with traditional simulation. Not only do they require no hardware installation or space for a workstation on-premise, but they are also inherently scalable; users only pay for what they use. Integrating cloud-based simulation into thermal management design also holds the potential for reducing enormous costs in the product development process. The more realized a product becomes to its final version the more costly modifications become. With simulation tools, designers can identify a problem before money is spent on producing physical prototypes. This is why Raycore Lights use SimScale to shorten the design and prototype lifecycle of their products. In addition to reducing the overall time-to-market, simulation can mitigate unforeseen costs.

Dispelling myths about electronics cooling can open up the world of simulation to engineers and help them analyze thermal management and optimize their design for best results and improved products.