Passivhaus is a building standard initially developed for homes in Germany. It has since expanded globally and has been modified to suit other building types, including schools and offices. The critical features of Passivhaus buildings are that they are designed for occupant comfort and indoor air quality, and consume very little energy, specifically for heating and cooling. The standard applies strict design and construction criteria to the entire building lifecycle. High levels of insulation and air-tightness mean that energy leakage is minimized to deliver low energy buildings. The energy lost through fabric and exfiltration is so low that a minimal amount of additional power is needed to keep the space comfortable, and this is typically achieved through natural heat gains from people, equipment, and passive solar gains. In the UK, for example, this results in a 75% reduction in annual operational energy use when compared to buildings meeting the minimum energy requirements from UK building regulations.

To achieve the Passivhaus Standard typically involves:

- Design modeling using the energy design package, Passive House Planning Package (PHPP), from the earliest stages of the design process.

- High-performance insulation levels

- A very high-performing, thermally insulated building envelope and fabric (windows, walls, frame, doors, roof, and floors).

- An airtight building fabric

- A ‘thermal bridge free’ construction that avoids adventitious heat loss through structural and fabric joins.

- A mechanical ventilation system with efficient heat recovery for fresh air supply and adequate ventilation effectiveness to provide a high level of air quality.

Passivhaus is becoming increasingly popular. At the time of writing, in the UK alone, there were 289 certified Passivhaus projects completed with a further 180 under development. This Passivhaus projects database illustrates all current certified Passivhaus projects in the UK. Additional Passivhaus databases contain more extensive lists of all Passivhaus projects EU-wide. The standard is now so well developed that a 178m high residential tower is being built in the city of Vancouver, Canada. It will be the tallest Passivhaus building in the world and contains 480 low energy residential units.

Designing a Passivhaus building to such exacting standards is a complicated task. The standard forces a designer to consider much more of the building physics at an earlier stage of the building design. Whereas detailed design simulation for energy, loads, and ventilation might have come at the engineering stages, by specialist M&E engineers, it is now integrated into the whole standard and features heavily early on. A Certified Passivhaus Designer is trained on how to use this tool (PHPP), and even building components have their Passivhaus certification, which ensures an aligned and trustworthy supply chain.

Specialist design software tools are encouraged. From having a better understanding of thermal bridging, condensation risk and moisture, to sizing ventilation openings, there are many tools used by designers to capture as much building physics as possible. One such tool is computational fluid dynamics (CFD), a type of engineering simulation.

CFD for Passivhaus

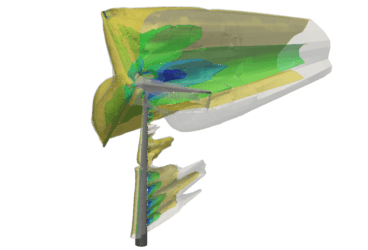

CFD models the behavior of fluids (liquids and gases). CFD is used in most types of engineering design to evaluate the impact of heat transfer, fluid and material properties, and the operating environment of whatever is being designed. In building physics, CFD is often used to quantify and visualize the impact of the three main heat transfer mechanisms (conduction, convection, and radiation). A user can then evaluate their impact on thermal comfort, air quality, building aerodynamics, and HVAC design and sizing.

For a Passivhaus building aiming to be low-energy and have high levels of air quality, several immediate advantages of using CFD spring to mind:

Building Fabric

CFD is used to simulate the material properties of walls and windows. Properties like thermal conductivity, specific heat capacity, thickness, and density can be applied to evaluate the impact of varying wall thicknesses, analyze the properties of insulating materials or calculate heat loss through glazing.

Indoor Air Quality

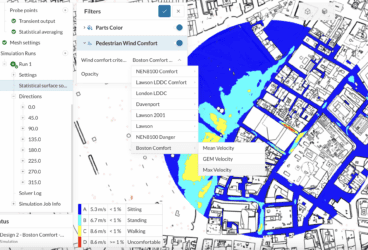

CFD is used to simulate the airflow in and around a building. A user can model various configurations of window sizes and openings and assess how fresh outside air enters, circulates and leaves the facility. CFD is critical in being able to design for indoor air quality correctly. Outputs include the mean age of air (ventilation effectiveness), visualization of air circulation in the room, a spatial assessment of CO2 from occupants, and a temperature profile of the space. A more detailed analysis might include further coupling the outdoor and indoor environments in the simulation by calculating the climate file-derived wind pressure coefficients on the building envelope.

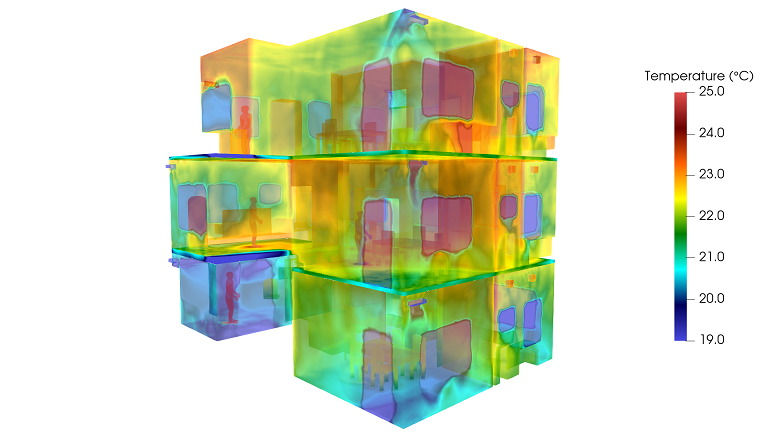

Thermal Comfort

A high level of occupant comfort is a centerpiece of the Passivhaus standard. CFD can be used to quantify the comfort of occupants by calculating the indoor temperatures in the room, indoor surface temperatures, and comfort indices such as predicted mean vote (PMV) and percentage of people dissatisfied (PPD)—two widely used comfort metrics referenced in building standards and rating systems.

Passivhaus Design Example

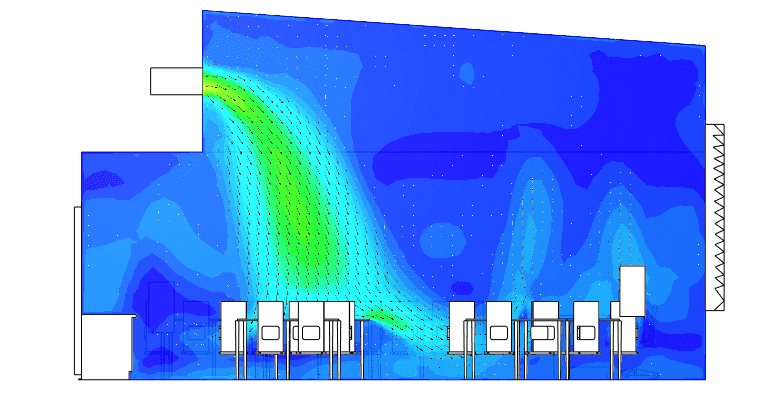

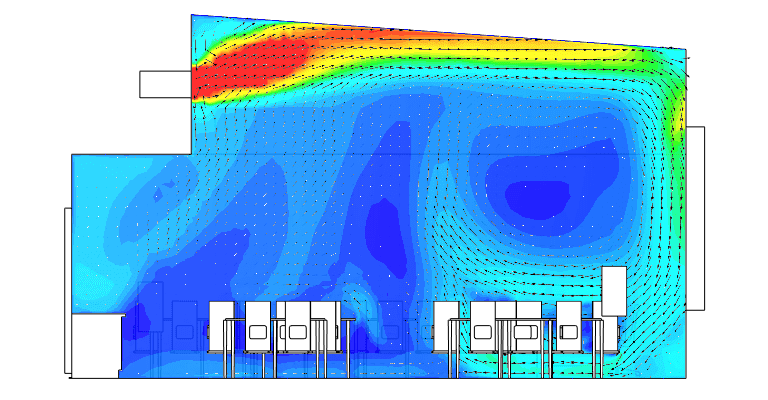

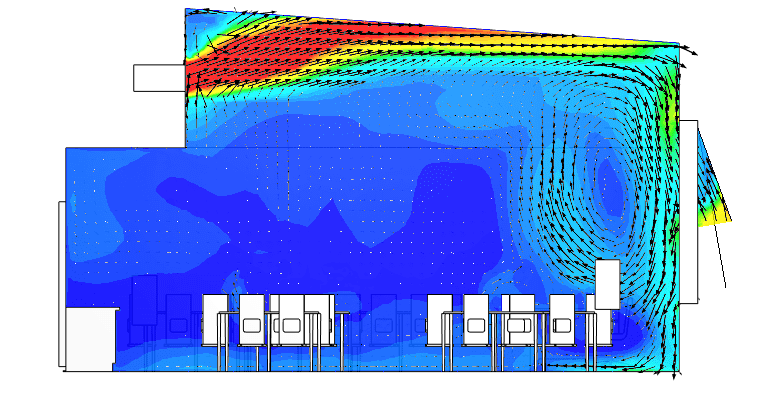

Architype used CFD to conduct a sensitivity analysis of their window opening strategy as part of an internal study. An essential requirement was to understand the relative ventilation and comfort advantages of several windows and mechanical ventilation configurations.

The three images below show internal air circulation patterns with different configurations of supply diffuser and window opening. Small changes to these systems can have a significant impact on how fresh air and air quality are defined within a space. Only a CFD tool can correctly calculate and visualize this phenomenon.

Summary

A Passivhaus building is meticulously designed, constructed, and maintained according to particular criteria. These criteria have been developed to produce energy-efficient and comfortable facilities. CFD, as an analysis tool, is incredibly useful in optimizing the thermal and ventilation parameters of the building.

Learn more about the Passivhaus design standard and CFD simulation here:

- Architype Validates Their Classroom HVAC System Against the Passivhaus Standard With SimScale

- Thermal Environment and Indoor Air: Guide for Building Designers

- Natural Ventilation Validation with CFD Software in the Cloud