Most of us who might have walked through beer factories have tried to understand the overall culinary process of beer brewing. With the Oktoberfest taking place in Bavaria every year, the topic becomes very popular.

A simple online search for the steps involved in the brewing process gives an insight into this delicate art. There are multiple websites, which are dedicated to addressing the brewing process in detail. Some of the steps include:

- Brewing the beer — Involves boiling of pale malt extract and hops with water. Further on, the grains are steeped frequently to add color and flavor.

- Cooling and fermenting — Here the hot mixture, now known as wort, is cooled to room temperature and subsequently transferred with additional water. Once cooled, yeast is added and locked in an airtight container for fermentation.

- Priming and bottling — Once the beer is ready, it is transferred to another container for priming. Here sugars, such as corn sugar, are added, and then the beer is siphoned into bottles.

- Aging — Once the beer is bottled, it will need a further 2-6 weeks again during which the yeast will ferment the remaining sugar to create carbon dioxide. The carbon dioxide will naturally carbonate the beer.

Of course, the final, and possibly most important step—put the beer in the fridge and enjoy drinking!

SimScale’s CEO David Heiny tests the capabilities of the platform to solve a real-life engineering problem. Fill in the form and watch this free webinar to learn more!

Beer Brewing and Simulation

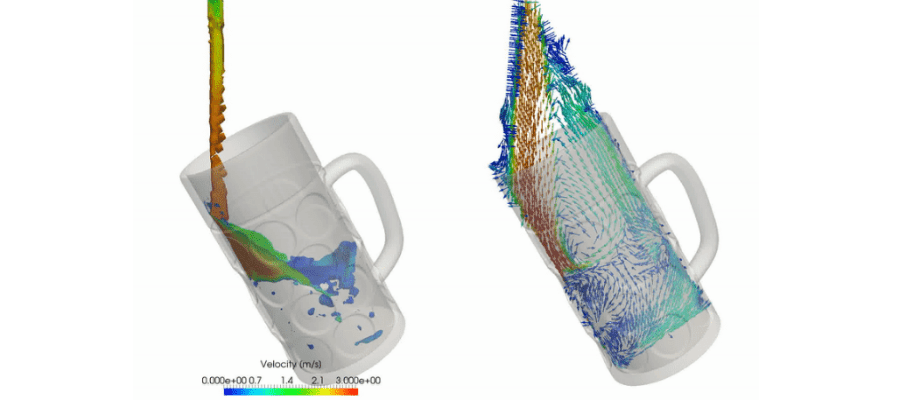

The natural question that arises here is how can simulations help, be it industrial or home brewing? There are several areas in which simulations can be highly helpful in improving the beer quality. Two of the main areas are fermentation and cooling. While fermentation is a more complicated thermo-chemical process, cooling is a much simpler thermal problem.

Cooling of Wort

An important aspect of the brewing process that can control the taste of the beer is the cooling of the wort. Here, the boiling wort is cooled down very quickly to a temperature at which the yeast can survive. Yeast has a survival temperature between 30-40 ℃ and is most comfortable around the body temperature. High temperatures, of even 50℃, can be significantly damaging to the survivability of the yeast. Hence, the boiling wort needs to be drastically cooled. In homebrewing, the general volume is smaller but in the beer industry, the volume is much bigger.

In addition to the survival temperature of the yeast, it is also important to consider the production of byproducts such as the off-flavors produced by sulfur compounds and other contaminants. Fast cooling reduces the production of these byproducts. Some of the simple ways of cooling could be adding ice or placing the entire unit in an ice bath. Unfortunately, both of these techniques are not efficient.

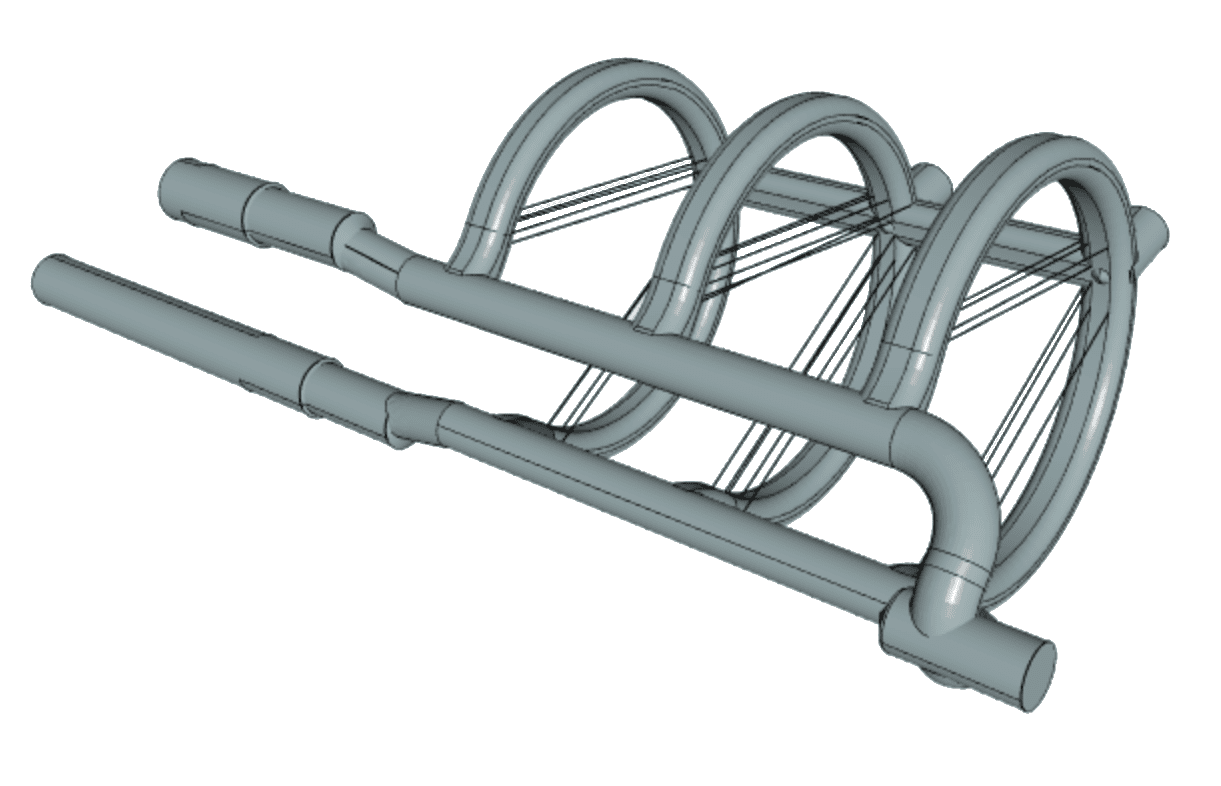

Alternatively, wort chillers are used and they consist of long helical pipes that can be immersed in the wort container at the end of the boiling process. Cold water is circulated through the pipes to cool the boiling wort. An inspiration for such a wort chiller can be found in the “Flow Analysis of a Cooling System” project available in the SimScale Public Project Library. A simple model of the wort chiller is shown in Fig. 02.

In the above project, only a fluid flow analysis is considered as an incompressible flow process. However, an additional external volume can be added to model the overall process as a conjugate heat transfer process. Alternatively, the brewing process can also involve using a heat exchanger.

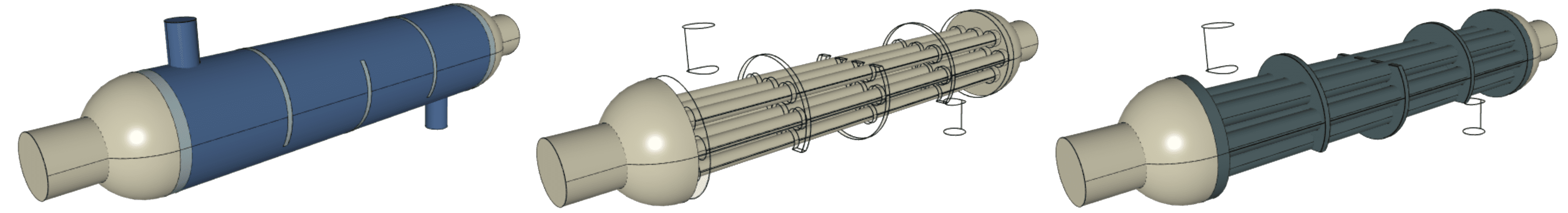

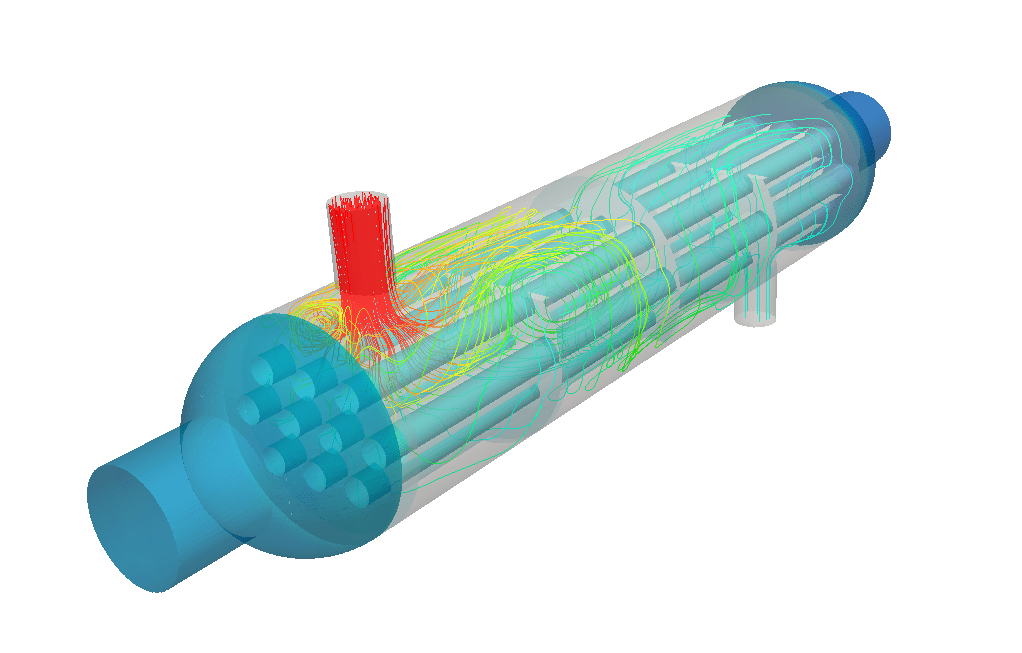

The conjugate heat transfer analysis of a heat exchanger in the library provides an appealing template for modeling the cooling of wort using a heat exchanger. A heat exchanger is a device used to transfer heat between one or more fluids. The heat exchanger, shown in Fig. 03, uses water as a coolant to rapidly remove the heat from the boiling wort.

The cooling process can be modeled as a conjugate heat transfer process. The heat exchanger is made of copper and the cooling liquid is water. The hot wort passes through the outer tubes while the cold water passes through the inner tubes. The cold water cools the hot wort to the desired temperature as it passes out of the heat exchanger.

As the inner fluid (water) flows through the inner pipes (grey colored), the wort is passed through from end to end in the outer set of pipes (blue colored).

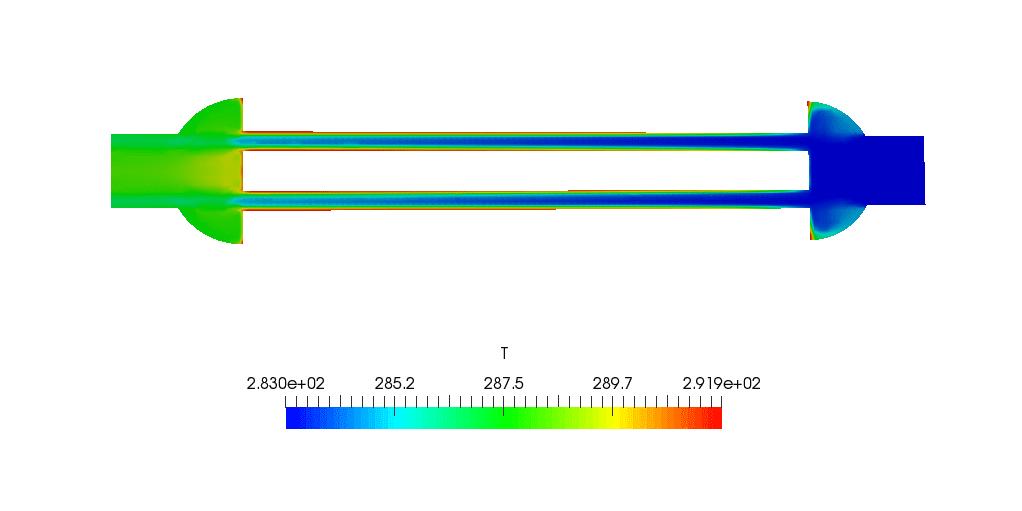

The temperature profile of the outer fluid is shown in Fig. 04 and the inner fluid in Fig. 05. In Fig. 04, the hot wort passes through the heat exchanger through the top opening and into the outer pipe system. As the wort passes through the heat exchanger, the heat energy is transferred to the coolant liquid (or water here). As the wort exits the heat exchanger from the bottom outlet, the wort is cooled down to the desired temperature (here room temperature).

Similarly, Fig. 05 shows the temperature profile of the coolant liquid (or water) flowing in the inner tubes. As it can be seen, the water enters on the left side at low temperature and exists on the right side. As the water exits, the temperature of the water is higher due to the heat absorbed from the wort.

Such a heat exchanger is the most efficient and fastest way to cool the boiling wort. A simulation (CFD analysis in this case) of the heat exchanger process, as shown above, can significantly help improve the brewing process and render more tasty beer.

Fermentation

Another aspect of the brewing that can be modeled in an ad hoc manner is the process of fermentation. The fermentation process is reasonably complicated and involves reaction dynamics of various chemical processes. The process can last from a few days for a simple Ale to several weeks for a Lager. This is the point during the brewing process when the brewer decides on the type of beer and adjusts the temperature accordingly. Considering an Ale, the temperature is adjusted to about 65-76 degrees, while for the Lager, it is much lower at around 45-55 degrees. At these temperatures, the yeast consumes all the sugars. Even after the fermentation stops, the yeast continues to absorb the off-flavors. Once the off-flavors have been removed, the yeast becomes dormant and settles down at the bottom of the fermentation vessel.

Several people have studied the beer fermentation model. Of their papers, the prominent one is the work of Gee & Ramirez [1]. As discussed in the paper, the process of fermentation involves heat generation due to the breaking down of sugars (Glucose, Maltose, and Maltotriose). In addition, ethanol and biomass production rates, production of amino acids (nutrients), and production of fused alcohols-esters (for flavors) also need to be accounted for.

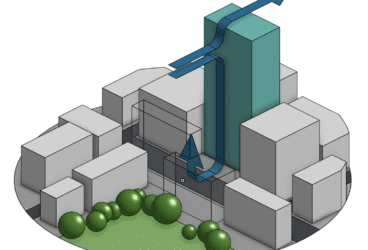

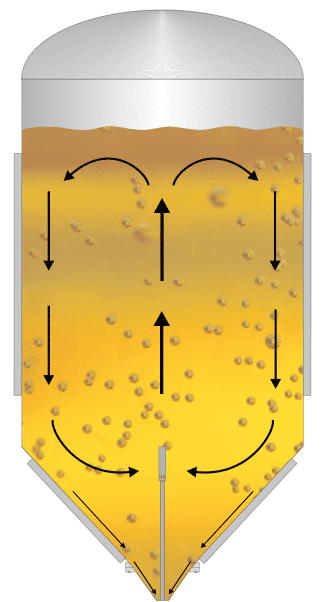

Overall, all these chemical changes lead to heat generation and a natural convection process. The rates of individual reactions and their heat generation can be calculated through chemical reaction equations. The process inside can be modeled as a natural convection process as shown in Fig. 06.

Fig 06: Fermentation during the beer brewing process. This can be considered a natural convection process.

Currently, SimScale does not facilitate solving pre-defined equations related to the chemo-mechanical process here. But this is definitely a module to look forward to. However, SimScale already facilitates CFD simulations that allow modeling of natural convection processes. The overall fermentation process can be considered to be a convective flow process with an internal source of heat. Some examples of these ideas are available in the public project library such as the convective flow with an internal heat source (for example, a light bulb).

Conclusion

Overall, beer brewing is a complex chemo-thermo-mechanical process and is highly intricate. No technology exists that can simulate the complete process. In fact, despite brewing beer for centuries, there are several aspects of brewing that remain a mystery, such as the dependence of the beer taste on the local water. Yet, the intermediate steps involved can be easily simulated using today’s computational technologies to improve the overall quality of the beer.

Discover all the simulation features provided by SimScale. Download the document below.

References

- D. A. Gee, W. F. Ramirez, A Flavour Model for Beer Fermentation, Journal of the Institute of Brewing, Volume 100(5), pp. 321-329 (1994)