As the highest level of motorsport, Formula 1 is luring millions of fans every week to their television screens. F1 is not only a competition between the best drivers in the world, it is also a race between thousands of highly passionate engineers who are working day and night behind the scenes to find another thousandth of a second advantage.

Throughout the many decades of Formula One racing, F1 teams have been innovation pioneers, generating groundbreaking technologies that have transferred over to mass production of automobiles, like lightweight construction and traction control. And today, F1 continues this innovation as decisive drivers of simulation technology.

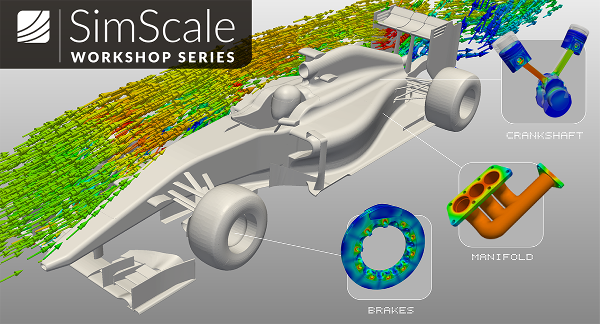

We are very proud to announce our SimScale F1 engineering simulation workshop, which is free and open for all existing SimScale users, as well as for all engineers and students who are interested in learning something about simulation. The workshop series consists of five one-hour courses, held on Thursdays at 4:00 p.m. Central European Time, starting March 19th.

The overall aim of the workshop is to conceptualize an F1 car, which will then be tested with the help of SimScale’s 3D engineering simulation platform. We are absolutely delighted to have Nic Perrin, head of trackside engineering at Manor F1 and president of PERRINN F1 Racing, as a guest speaker for the first workshop on March 19th, where we will dive into the aerodynamics analysis of the PERRINN F1 car.

Other workshop topics include thermal stress analysis, flow analysis, modal analysis, and static stress analysis, all providing a good overview of the functionality of the SimScale platform.

We want to give all participants the opportunity to learn directly from our experts, submit questions and exchange ideas with other users. In our interactive workshop series, everyone has the opportunity to experience simulation through practical application and examples, and to get direct feedback on their own submissions.

The workshop takes place in an online classroom so there is no need to travel. Participants also get a one-week free trial period for each course, which begins one day prior to each workshop.

In addition, those who join all five workshops, and complete at least one homework assignment simulation each week, will receive an invitation for a future session of SimScale Professional Training, with a value of €500, and a certificate of course completion for your resume.

Update: This simulation workshop has ended. Watch the recording here.

To discover all the simulation features provided by SimScale, download the document below.