Rotating equipment – the mechanical heartbeat of countless industries – presents some of the most fascinating and complex engineering challenges.

From maximizing efficiency in a jet engine’s turbine to ensuring the reliable, vibration-free operation of a simple industrial pump, the rotating component is where performance and reliability are won or lost.

What is rotating equipment?

Simply put, rotating equipment is any machinery that relies on rotational motion to perform its function. Unlike static equipment (like pipes or storage tanks), these devices are designed to convert energy into mechanical motion, often for moving fluids or generating power.

Common examples span a wide range of industries:

- Pumps (Centrifugal, Axial)

- Turbines (Gas, Steam, Wind)

- Compressors (Centrifugal, Axial)

- Fans and Blowers

- Motors and Generators

- Propellers and Impellers

What is the difference between static and rotating equipment?

The main difference between static and rotating equipment is movement.

- Static equipment (like pipes, tanks, or heat exchangers) is stationary and has no moving parts.

- Rotating equipment (like pumps, turbines, or motors) uses spinning components to actively create motion or generate power.

Rotating equipment types in depth

Let’s have a look at the different types of rotating equipment in a bit more depth.

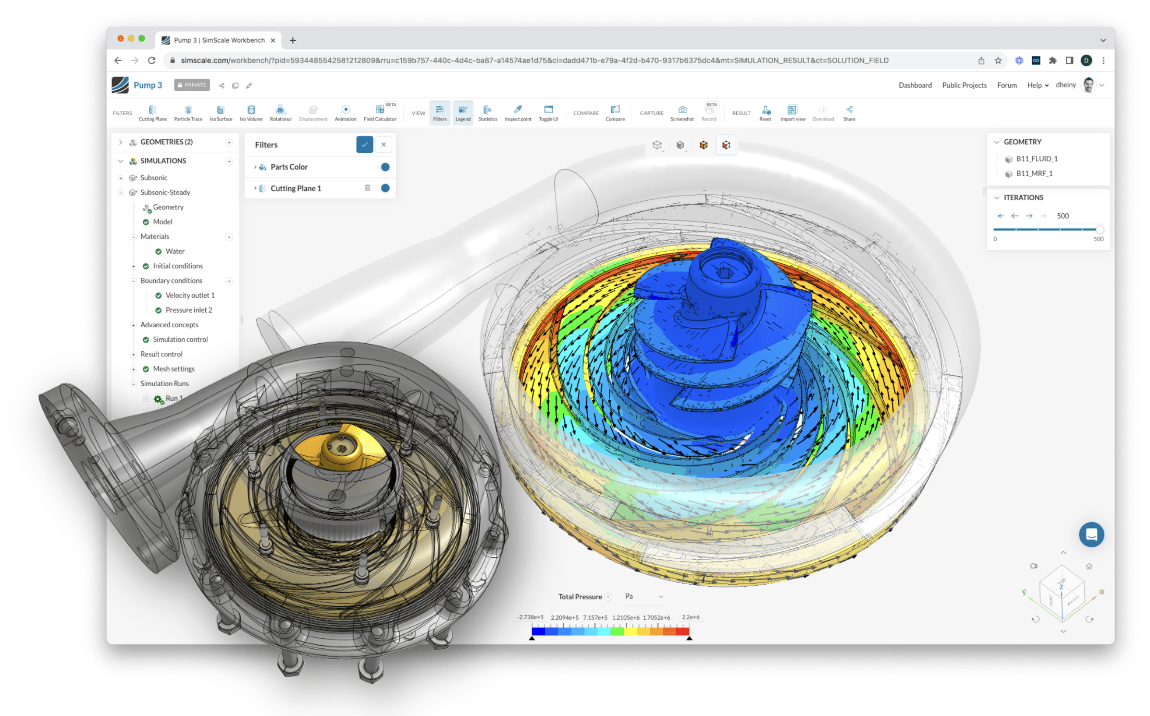

Pumps (Centrifugal, Axial)

Pumps stand as the workhorses of industry, hydraulic machines designed to transport fluids by converting rotational kinetic energy into hydrodynamic energy. The most common types, centrifugal pumps, use a rotating impeller to fling fluid outwards, while axial pumps use a propeller-style mechanism to move fluid along the shaft’s axis. From water supply systems to chemical processing, their applications are endless. But how can one optimize their performance and prevent damaging issues like cavitation? This is where modern engineering simulation steps in, allowing engineers to digitally visualize flow patterns and pressure zones to achieve design excellence before a physical prototype is ever built.

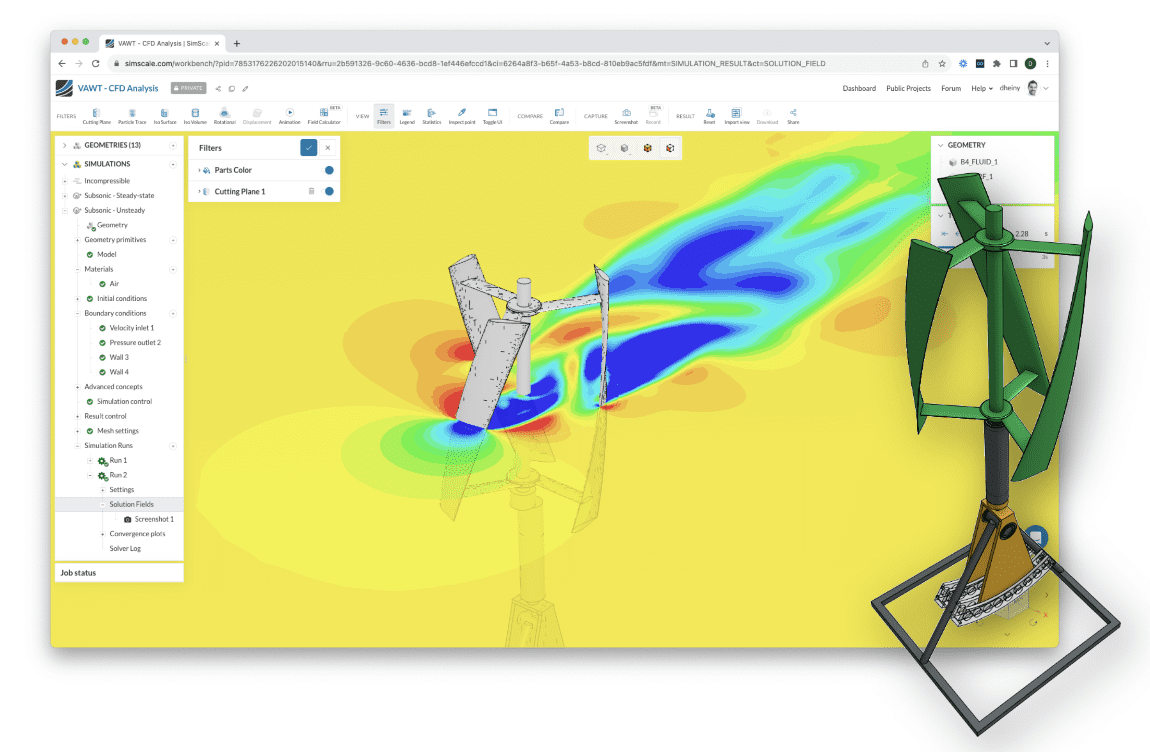

Turbines (Gas, Steam, Wind)

Turbines are critical in our pursuit of energy, acting as sophisticated engines that extract energy from a fluid flow and convert it into useful rotational work, most often to power a generator. Whether it’s a gas turbine using hot combustion gases, a steam turbine driven by high-pressure steam, or a wind turbine capturing the kinetic energy of the air, their core principle is to harness natural forces. The design of their complex blades is paramount to performance. Cloud-native simulation platforms offer a robust framework for modeling these intricate fluid-structure interactions, helping engineers optimize blade geometry to maximize efficiency and reliability.

Compressors (Centrifugal, Axial)

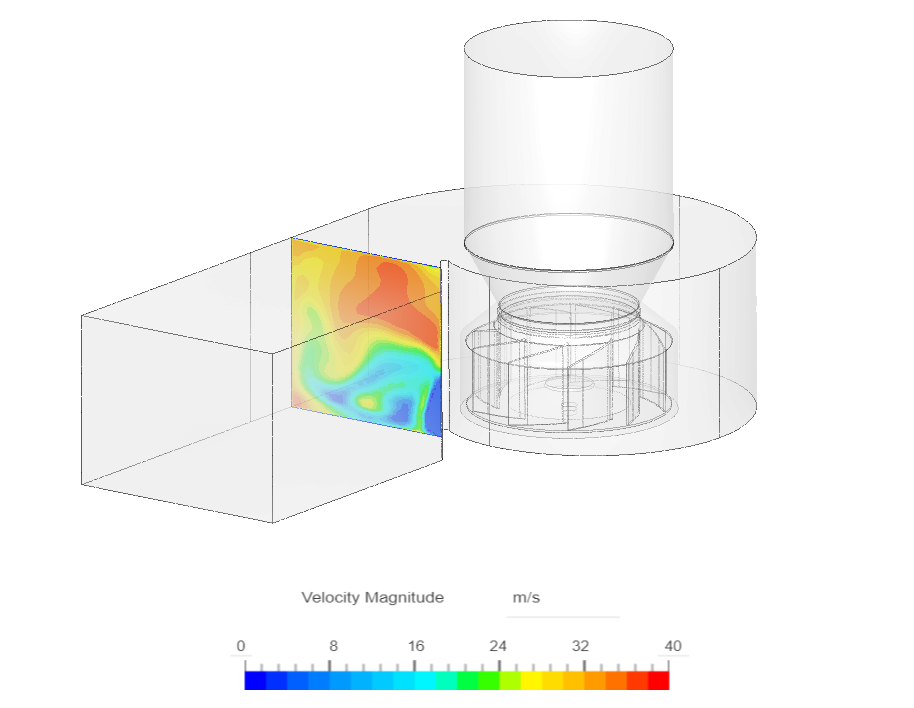

Compressors are vital machines whose primary function is to increase the pressure of a gas by reducing its volume. Like pumps, they are commonly found in centrifugal (radial) and axial flow configurations, each suited for different pressure ratios and flow rates. These devices are the heart of everything from jet engines and industrial refrigeration to gas pipeline transport. Achieving high efficiency and a stable operating range is a key design challenge. Using computational fluid dynamics (CFD), engineers can meticulously simulate the high-speed, complex flow through blade passages to optimize designs and minimize energy losses.

Fans and Blowers

While often grouped with compressors, fans and blowers are specifically designed to move large volumes of air or gas, typically at a much lower pressure differential. Their function is essential for ventilation in buildings (HVAC), cooling electronics, or supplying combustion air in industrial furnaces. The main challenge in their design is to achieve the required flow rate while minimizing power consumption and acoustic noise. Engineering simulation plays a key role here, allowing designers to analyze airflow, test blade profiles, and visualize turbulence to create quieter and more efficient systems.

Motors and Generators

These two devices are the cornerstone of our electrified world, managing the conversion between mechanical and electrical energy. A motor takes electrical energy and converts it into mechanical rotation to drive a pump, fan, or compressor. A generator does the exact opposite, taking rotational energy from a turbine and converting it into electrical energy for the grid. Optimizing their design requires a deep understanding of electromagnetics and thermal management. Multiphysics simulation is crucial, enabling engineers to analyze magnetic fields, predict heat buildup, and ensure the structural integrity of these fundamental machines.

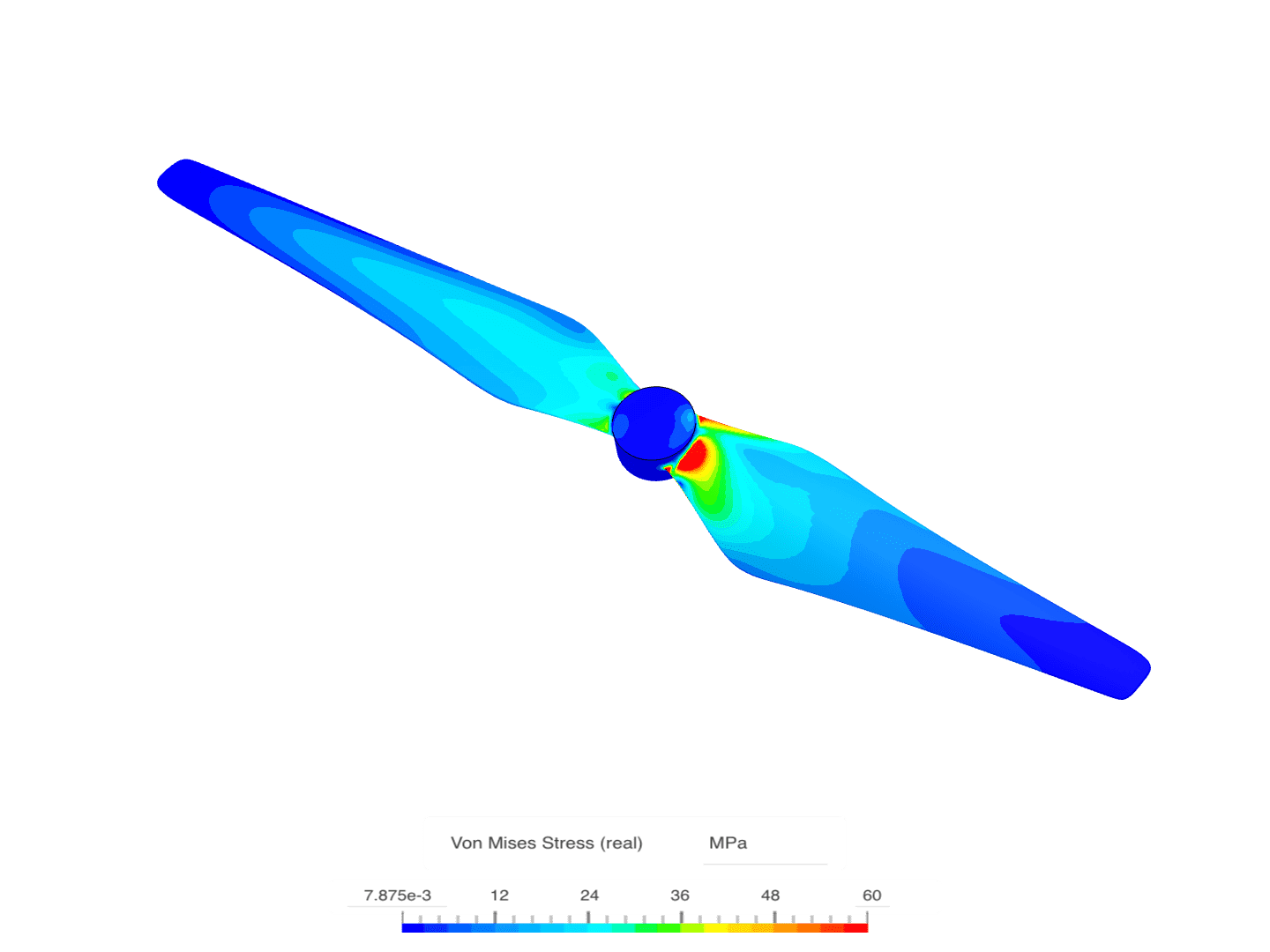

Propellers and Impellers

At the very heart of nearly all turbomachinery, you will find a rotating component designed to interact with a fluid: the propeller or the impeller. An impeller, such as one in a centrifugal pump, is designed to transfer energy to the fluid, increasing its velocity and pressure. A propeller, used for propulsion or in a turbine, interacts with the fluid to create thrust or extract work. The specific geometry of these components—their blade curvature, angle, and number—is the single most critical factor in the machine’s overall performance. Their design is a perfect use case for simulation, which allows for detailed flow analysis to maximize efficiency and minimize wear.

Rotating equipment in our public projects

Here is a range of rotating equipment that has been simulated with SimScale by our community.

Rotating equipment challenges

The continuous operation of rotating equipment is fundamental to global infrastructure, from power generation to manufacturing. Efficiency and reliability failures carry a massive cost. For instance, even a one percent drop in efficiency across a fleet of industrial pumps or compressors translates into millions of dollars in wasted energy annually. Any component failure driven by vibration or fatigue can trigger unscheduled downtime, which instantly halts production or utility service.

Beyond these operational costs, the industry is now facing unprecedented pressure driven by global Net-Zero targets and evolving sustainability mandates. This shift requires nothing less than a revolution in design, pushing engineers to develop machines that achieve record-breaking efficiencies while incorporating new low-carbon technologies, such as advanced compressors for hydrogen or lighter, more powerful electric motors. Therefore, optimizing these machines isn’t merely about achieving peak performance; it is a business-critical requirement for safeguarding financial viability and ensuring operational continuity in a sustainable future.

Some examples of government mandated Minimum Energy Performance Standards (MEPS) are given below.

| Equipment Type | Metric/Class | Example Regions/Mandates | Reference |

|---|---|---|---|

| Electric Motors | IE3/IE4 Classes | EU: IE3 is the current base, with IE4 mandatory for motors between 75 kW and 200 kW (as of July 2023). | EU Commission Regulation 2019/1781 |

| Industrial Pumps | Minimum Efficiency Index (MEI) | European Union: Requires MEI >= 0.40 for certain rotodynamic water pumps, with >= 0.70 being the benchmark for the most efficient models. | EU Commission Regulation 547/2012 |

| Industrial Pumps | Pump Energy Index (PEI) | United States (DOE): Sets maximum allowable PEI values (e.g. PEICL <= 1.00) for clean water pumps, enforced since January 2020. | US DOE Energy Conservation Standards for Pumps |

| Air Compressors | Package Isentropic Efficiency | United States (DOE): Standards for certain oil-flooded rotary air compressors became mandatory on January 10, 2025, based on minimum isentropic efficiency at specific flow rates. | US DOE Final Rule 85 FR 1504 |

Simulating rotating equipment with SimScale

Engineering simulation provides the vital advantage needed to tackle the complex challenges of rotating equipment proactively. By modeling real-world physics in a virtual environment, designers can rapidly explore changes and predict performance before a prototype is ever built, leading to significant cost reduction, increased reliability and lifespan, and accelerated time to market.

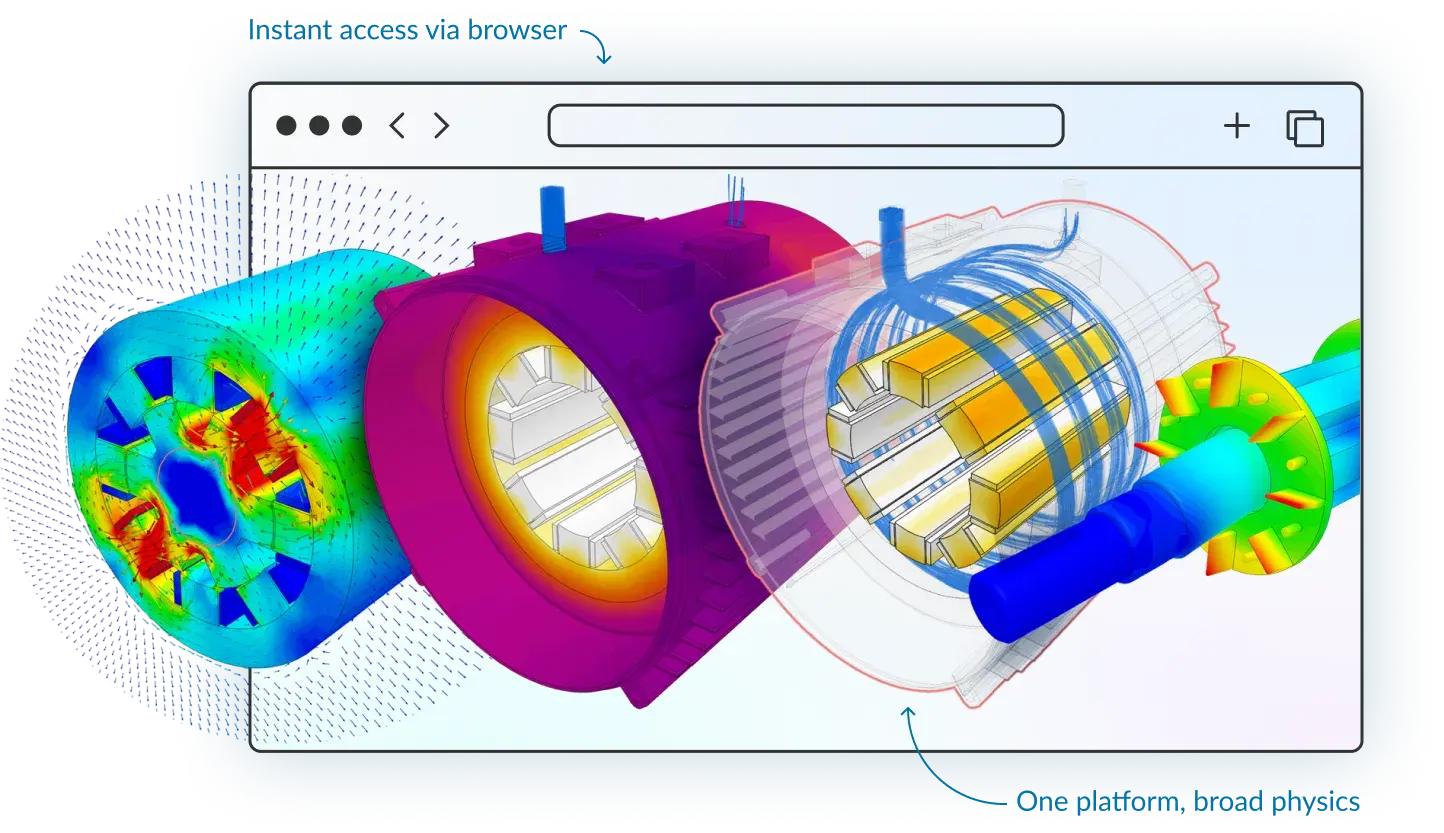

At SimScale, we are committed to providing accessible, high-performance simulation tools right in your web browser. For rotating equipment, our platform offers a powerful, validated suite of simulation types across fluid dynamics, structural mechanics, and electromagnetics.

Computational Fluid Dynamics (CFD)

To master the fluid flow within your turbomachinery, SimScale’s online CFD simulation capabilities offer two primary approaches. For initial design exploration and quickly mapping basic performance curves (like pump curves), the Multiple Reference Frame (MRF) method provides a computationally fast, steady-state approximation. However, for maximum fidelity in predicting complex phenomena—such as rotor-stator interactions, pressure pulsations, or cavitation—the Transient Analysis utilizing the highly accurate Sliding Mesh technique is essential. Furthermore, you can accelerate your entire development cycle by using Parametric Studies to automatically run dozens of variations (different speeds, flow rates, geometries) in parallel, efficiently generating a full performance map.

Read how Hazleton Pumps generated performance curves 100x faster with SimScale.

Finite Element Analysis (FEA)

Structural integrity and vibration avoidance are paramount for rotating equipment reliability. SimScale’s FEA tools focus on guaranteeing these factors. By conducting Rotational Modal Analysis, engineers can compute natural frequencies while accounting for rotational effects (centrifugal forces), which is crucial for identifying and avoiding critical speeds that lead to destructive resonance. The results are used to generate Campbell Diagrams for definitive vibration diagnosis. For detailed assessment, Harmonic and Transient Analysis allows designers to predict dynamic stresses resulting from forces like unbalance, ensuring the component’s fatigue life is sufficient.

Learn more about Rotational Modal Analysis and Campbell Diagrams on the SimScale Blog.

Electromagnetic (EM) Simulations

Electric motors and generators are a critical subset of rotating equipment, and their efficiency is governed by electromagnetics. SimScale’s EM solvers accurately calculate crucial machine characteristics like magnetic fields, flux, and torque output, which is necessary for meeting strict IE4/IE5 efficiency standards. To capture real-world performance accurately, these results can be integrated into Multiphysics Coupling workflows, linking electrical losses (heat) to a thermal analysis, which then feeds into a structural analysis to assess the impact of temperature on material stresses

Learn more about Multiphysics Simulation in SimScale.

Why SimScale for Your Rotating Equipment Design?

SimScale’s commitment to the rotating machinery sector is all about making advanced physics accessible. Our cloud-native platform is specifically engineered to overcome the common barriers of traditional CAE:

- Speed and Parallelism: Run complex transient and parametric studies in parallel, reducing the turnaround time from days to hours.

- Accessibility: No heavy software installation or specialized hardware is needed. Access powerful HPC from your web browser, anywhere.

- Ease of Use: An intuitive interface and validated workflows, including specialized rotating machinery meshing, allow design engineers to conduct simulations without needing deep simulation expertise.

By leveraging SimScale, your team can Simulate Early, Simulate More, and Simulate Now—leading to faster design cycles, highly optimized products that meet global efficiency mandates, and maximum operational reliability for all your rotating equipment.

FAQs

The main types of rotating machines are pumps, turbines, compressors, fans, blowers, motors, generators, propellers, and impellers.

Rotating equipment (like pumps or motors) uses spinning parts to create motion or power. Static equipment (like pipes or tanks) is stationary and has no moving parts.

Rotating machines are ones that rely on rotational motion to function. Common examples include pumps (moving liquids), compressors (pressurizing gas), turbines (extracting energy), and motors (creating motion).

The difference is movement. Fixed (static) equipment is stationary, like a pipe or storage tank. Rotating equipment has spinning components to do work, like a turbine or a fan.