A common problem in product design—particularly in electronics cooling—is managing thermal conditions for optimal efficiency. The core of the challenge is designing energy-efficient microprocessors and printed circuit boards (PCBs) that will not overheat.

A frequently overlooked aspect of thermal management problem-solving is architectural design. Whether it’s a private home, an office building, or a dedicated server room, architectural considerations can have a huge impact on the thermal management solutions available.

To tackle and alleviate the difficulties and inefficiencies that arise as a result of heat, engineers employ different cooling systems to manage conditions. These systems can be divided into two main categories: those with active cooling and those with passive cooling techniques. But what is the difference between them?

Active vs. Passive Cooling Passive Cooling

The advantages of passive cooling techniques lie in energy efficiency and lower financial cost, making it an astute systems design choice for the thermal management of both buildings and electronic products.

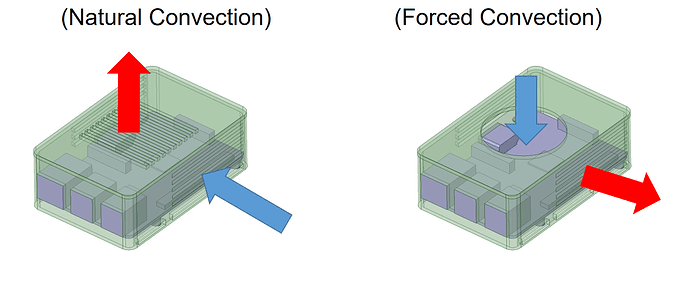

Passive cooling achieves high levels of natural convection and heat dissipation by utilizing a heat spreader or a heat sink to maximize the radiation and convection heat transfer modes. In architectural design, natural resources like wind or soil are used as heat sinks to absorb or dissipate heat. This leads to proper cooling of electronic products and thermal comfort in homes or office buildings by keeping them under the maximum allowed operating temperature. A growing trend in this regard can be witnessed in what is commonly known in the industry as passive houses.

To sum it up—passive thermal management is a cost-effective and energy-efficient solution that relies on heat sinks, heat spreaders, heat pipes or thermal interface materials (TIM) to maintain optimal operating temperatures.

Download ‘Electronics Cooling: The Ultimate Guide’ to learn everything you need to know about modern electronics cooling.

Active vs. Passive Cooling Active Cooling

Active cooling, on the other hand, refers to cooling technologies that rely on an external device to enhance heat transfer. Through active cooling technologies, the rate of fluid flow increases during convection, which dramatically increases the rate of heat removal.

Active cooling solutions include forced air through a fan or blower, forced liquid, and thermoelectric coolers (TECs), which can be used to optimize thermal management on all levels. Fans are used when natural convection is insufficient to remove heat. They are commonly integrated into electronics, such as computer cases, or are attached to CPUs, hard drives or chipsets to maintain thermal conditions and reduce failure risk.

The main disadvantage of active thermal management is that it requires the use of electricity and therefore results in higher costs, compared to passive cooling.

Download this free case study to learn how thermal simulation with the SimScale cloud-based platform helped QRC Technologies to implement advanced cooling techniques and optimize heat dissipation for its RF testing equipment.

Explore Thermal Analysis in SimScale

Simulation in Cooling Why Use Engineering Simulation Software for Active and Passive Cooling?

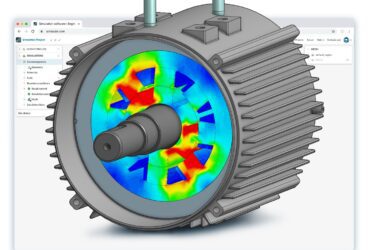

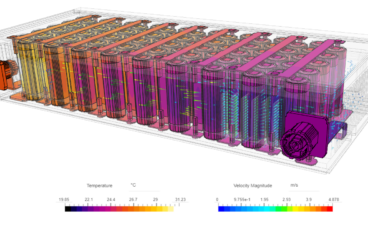

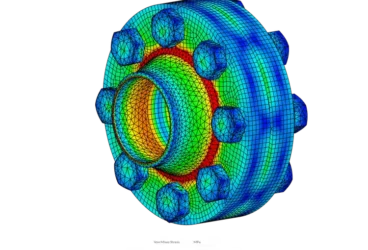

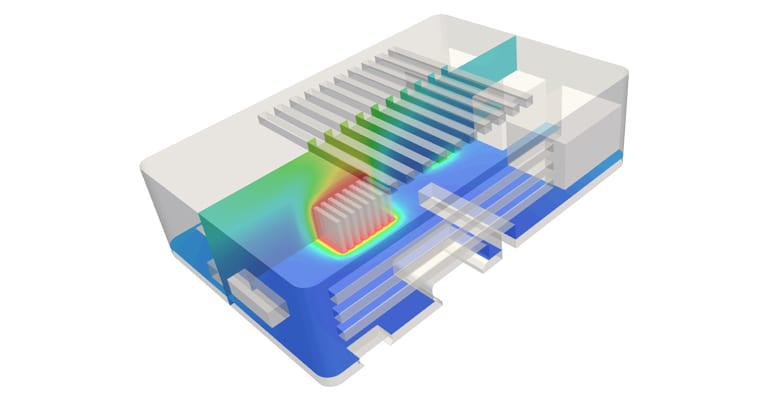

Early in the design phase, computer-aided engineering software can be used to virtually test fans, blowers, heat sinks, chips, PCBs, and even server rooms and buildings, for better thermal management.

By performing early-stage thermal simulations, designers can predict the airflow, temperature distribution, and heat transfer in systems. These analyses reduce the number of unnecessary physical prototypes, resulting in design process efficiency and significantly reduced costs. In a SimScale public project, a heat sink design was analyzed through conjugate heat transfer simulation, with the purpose of optimizing it to ensure proper cooling. If you’d like to use it as a template, just create a free Community account here and then copy the simulation.

Thermal analysis software can also help you make an informed decision when considering active and passive cooling techniques. This workshop recording and its step-by-step tutorial will help you compare active and passive cooling of a Raspberry Pi house by performing a simulation.

Despite the significant manufacturing cost reduction of electronic boards and prototype enclosures for devices, it is still a daunting and time-consuming task to analyze the thermal performance of a new design. Download this free case study to learn how the thermal performance of a printed circuit board was investigated with SimScale using thermal analysis.