VTOL Technologies was founded in 2008 in the UK, with the goal of the development, subsequent sale and operational service provision of long endurance lightweight portable beyond visual line of sight remotely piloted aerial systems, otherwise known as drones. Their products are targeted at network-based linear asset industries providing a new, automated, at much lower cost and safer aerial asset inspection capability. Their flagship product is the VTOL Flying Wing.

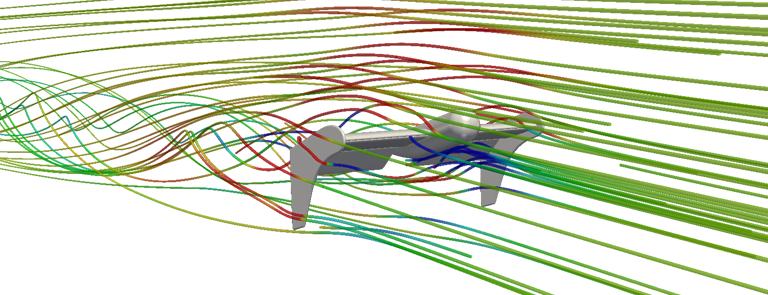

The main challenge VTOL Technologies’ team faced was to obtain reliable and accurate data on key aspects of their unmanned aerial vehicle. This included the aerodynamics, as well as the propulsion. SimScale allowed VTOL team to gather this data, better understand the aerodynamics and main characteristics of the drone for improving its performance and increasing the range and endurance.

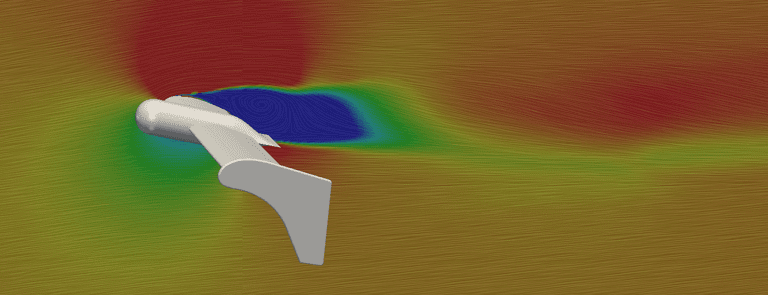

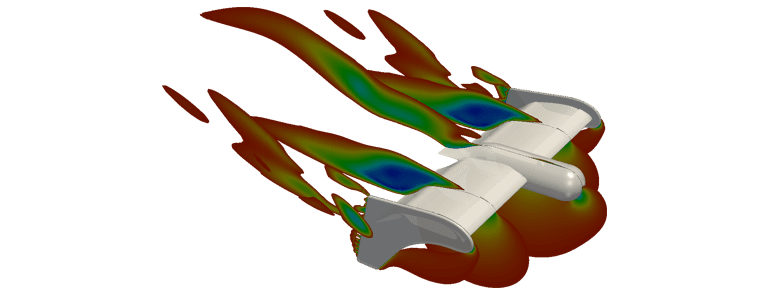

VTOL Technologies already worked on several projects with SimScale. One of them involved the development of ducted fans that were to replace the open rotor. The company wanted to investigate the performance of the ducted fan with different configurations, analyzing the hover and the cruise flight. For this, the engineers ran several simulations with SimScale and made design decisions based on the results.

Another project was focused on changing the configuration of their next-generation drone. The team changed the configuration of the fuselage with respect to the wing and wanted to understand the impact of the first modifications, as well as their benefits and disadvantages, before committing to more design alterations. The engineers also run simulations of their drone design to compare both configurations.

We realized that some of the simulations of our drone design could be run much quicker and better with SimScale. Also, we used to not have a good process established, but now with SimScale, we have a proper design methodology and a validation tool for all the design modifications and improvements.

Marta Marimon

Aeronautical and Flight Mechanics Engineer

Prior to using SimScale, VTOL Technologies tried another CAE software, but because they needed a transient solver, it was taking a lot of computational time to run just one simulation. In the project for improving the aerodynamic efficiency of their aircraft, the engineers at VTOL Technologies compared different configurations by running a set of CFD analyses on the incompressible regime. This approach was sufficient since the usual flight speeds of a drone are low.

“What I think is very good about the SimScale platform is the fact that it is cloud-based, and therefore you don’t need any special hardware. Since we are a small company and we just need simulation software at certain stages of the development process, we could not afford to buy the appropriate hardware that is required to use traditional on-premises simulation software. SimScale is a great solution for our company,” said Marta.

The simulations performed well. The SimScale support team helped in setting up the mesh, as this was the only point the VTOl team had a small difficulty. Once the mesh was properly set up, the simulations provided satisfactory results and the team gathered an output of the forces and moments to understand the performance of the drone.

In terms of results, for one of the configurations—which was blending the fuselage with the wing—VTOL Technologies reduced drag by 2% but had an increase of lift by 20%.

“This was a phenomenal result, we are very happy with it. This will enable us to improve the aircraft’s performance, range and endurance. My impression of SimScale was very good, to be honest. I think it’s a powerful tool and it has a very user-friendly interface. As we are not CFD experts, it helped a lot to get into the simulation field. The software, in general, is easy to understand quickly,” said Marta.

VTOL Technologies is currently developing the next generation of drones that will enable them to bring larger payloads and increase the range and endurance of each operation.

“With this development, I think SimScale will have an indirect impact on the company. With our new design methodology, which includes CFD and SimScale, we will be able to provide a much more attractive product to our customers and partners. Once the next generation of drones is completed, we will definitely use SimScale on our next project as well,” concluded Marta.

Sign up for SimScale

and start simulating now