Since 1984, Carlsson Autotechnik GmbH has been developing and selling grafting programs for Mercedes-Benz vehicles and providing key engineering services for other vehicle manufacturers including Citroen, Peugeot, Honda, Toyota and SsangYoung Motors.

The design and development of sports cars and their components require, besides know-how,

experience, and passion, the right tools and technologies.

While large automobile companies maintain a large number of development departments with their own test stations for engine, chassis, and body development, Carlsson is facing the challenges of managing the same tasks with limited resources. Playing a vital role in the automotive industry and especially in structural stress optimization, aerodynamics, and cooling, engineering simulation can remove technology barriers.

Benefiting from SimScale’s pay-as-you-go model, Carlsson’s team was able to use the simulations for everything they needed, paying only for what they used. Due to its browser-based deployment of software, computing capacity and data management, the SimScale platform enabled the engineers to do a flexible implementation of the whole simulation array without high fixed investments.

This helped our customer to apply fluid flow simulation in the aerodynamic development,

which was until recently only reserved for Formula One racing teams and automotive OEMs.

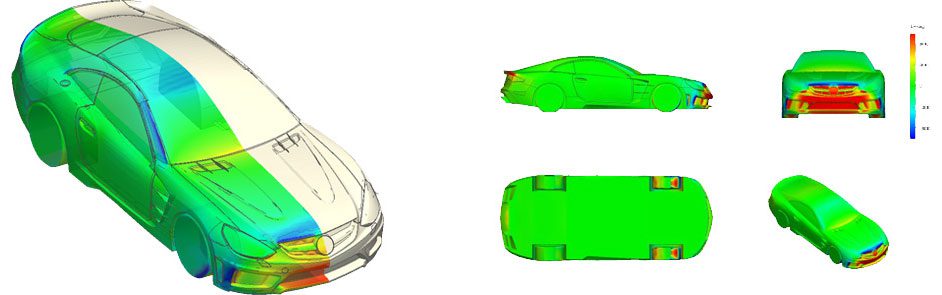

The 3D model of the vehicle shell had been prepared and subsequently uploaded and meshed on the SimScale platform.

The intuitive user interface for mesh generation allows the user to steer the resolution of the mesh fine granular in order to improve the accuracy of the simulation.

Due to the automatic identification of feature edges, various details of the complex geometry such as the lateral bearings and clearances were resolved within the hex-dominant mesh. Based on the various examples in the Projects Library, the immediate completion of the CFD simulation was possible: the settings had been transferred on the created mesh and the inflow velocity adjusted.

On the basis of the simulation results, it was possible for Carlsson’s engineers to examine and optimize the aerodynamics of the vehicle.

Besides the resulting forces for air drag and downforce—or rather the related dimensionless benchmarks that are calculated automatically—,there are various physical quantities available in the entire flow domain, such as pressure, velocity, and turbulence.

They can be visualized as desired with cuts and streamlines and subsequently saved as image files. In contrast to wind tunnel tests, the impact of a changed design could not only be quantified but also investigated in detail.

The overall costs of this simulation for Carlsson was €60 and the simulation working time was 5 hours.

On the basis of the simulation results, it was possible for Carlsson’s engineers to examine and optimize the aerodynamics of the vehicle.

Sign up for SimScale

and start simulating now