Downhole tools for oil drilling and well servicing are often pushed to the extreme. Operating conditions include pressure, load, temperature, and corrosive environments, while at the same time demanding designs call for the tools to be more compact. Prior to using SimScale, TechTree Engineering was limited to just using linear analysis, forcing them to make conservative assumptions to limit the rated working pressure and load ensuring the safe operation of their tools.

In an attempt to improve their analysis methods, Techtree Engineering turned to SimScale for two main reasons. First, the platform has a minimal upfront investment and no expensive hardware costs. Second, the cloud-based software allowed the team to work remotely, aligning perfectly with Techtree Engineering’s workflow and company model.

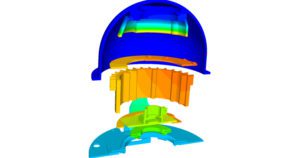

Techtree Engineering began using SimScale for nonlinear analysis to further analyze the component. Their analysis often required plastic material analysis, geometric nonlinearity, as well as contact nonlinearity. This, along with learning SimScale as a new software, presented some initial challenges for the team. However, the eagerness and quick response time of the SimScale support engineers helped Techtree Engineering to get meaningful results quickly.

Using SimScale allowed us to increase the rated load of several tools by up to 20%. In a competitive market, that gives our clients the edge they need over the competition.

Tyler Lindstrand

Engineer

Techtree Engineering found that they have been able to consistently and confidently increase the load rating of their tools, making both them and their clients more competitive.

The ability to immediately scale the solving hardware was extremely useful to their team. Techtree Engineering ran successful simulations in minutes by using 64 core machines that they could not solve locally on their laptops.

Techtree Engineering has now worked SimScale into their day-to-day design workflow. Using the cloud-based platform, they have more confidence to push their designs further, and have also been able to reduce the number of prototypes that were made by more accurately predicting the behavior of complex parts.

Sign up for SimScale

and start simulating now