Submer Technologies, S.L. is a technology company that focuses on the data center market and IT industry. Data center buildings consume inordinate amounts of energy to simply cool their servers, producing a huge carbon footprint that grows day by day with the growth of the Internet. This is set to continue as the global trends of digitalization and cloud computing further accelerate. Submer provides a solution to this challenge, allowing their customers to grow in an environmentally sustainable manner.

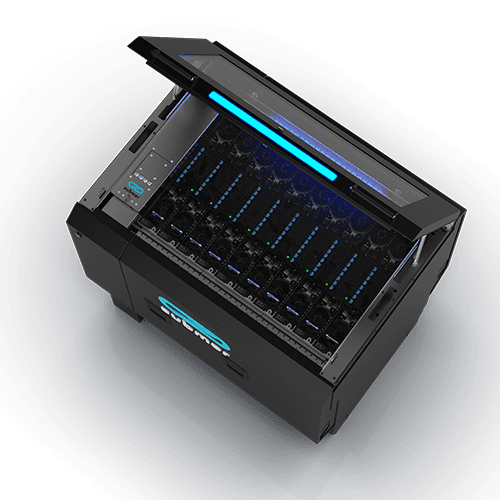

Submer Technologies’s own proprietary fluid and equipment (SmartPods) combine to make a liquid bath for cooling IT hardware. This takes advantage of the better thermal properties that a liquid phase material has over gas phase materials, such as air, for whisking away excess heat. Overall, this system can effectively cool electronics along with reducing cooling energy costs by up to 95% when compared to traditional air cooling.

When designing one of their SmartPods, Submer noticed that an electrical box needed to be placed very close to the IT tank where the cooled electronics are kept. Furthermore, due to spatial constraints, the clearances around the box were so tight that forced convective cooling of the box simply was not an option. To ensure the reliable operation of the components within the box, the temperatures needed to be decreased significantly, so Submer set out on finding the most efficient cooling solution possible.

With plenty of ideas and proposed solutions hypothesized, the team at Submer essentially needed a solution to quickly evaluate the feasibility of a multitude of designs. Access to the interior of the box was limited due to the spatial constraints method, limiting the ability to reliably test different setups physically. Therefore, rather than rely on traditional means, such as physical prototyping, Submer opted to accelerate their design cycle by incorporating a cloud-based simulation tool into their processes.

SimScale has allowed us to be quick and responsive to our product demands. It enables us to simulate anywhere in the world, with no restrictions on our hardware As a growing company, swift responses and actions are what we seek, and SimScale matches all of our criteria.

Jaime Pita

Submer Technologies, S.L.

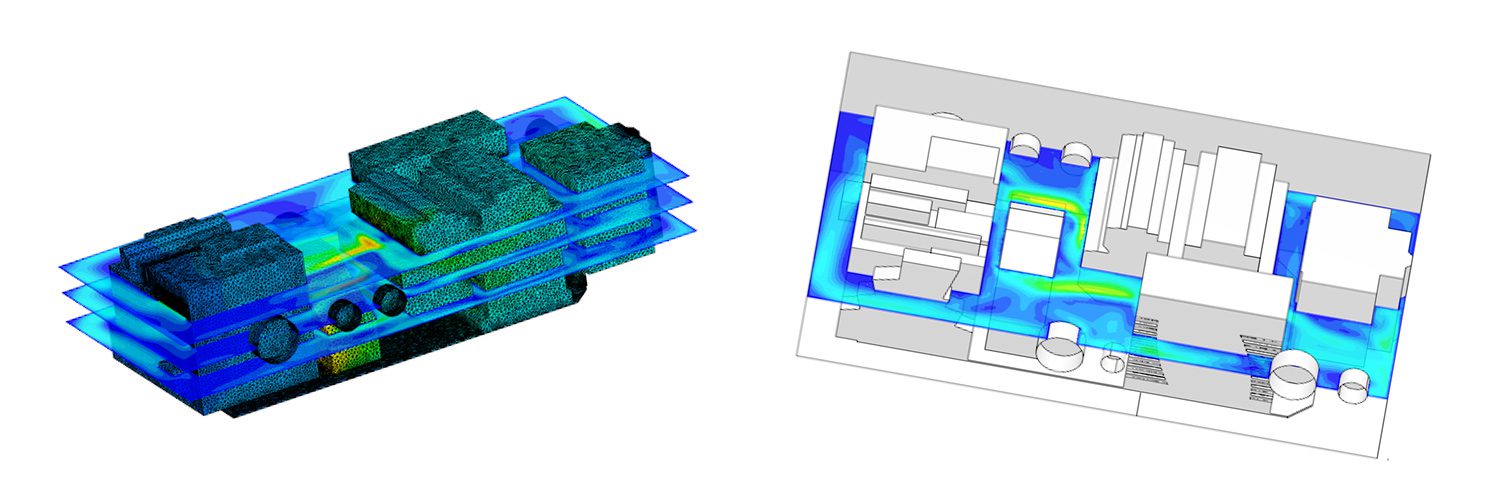

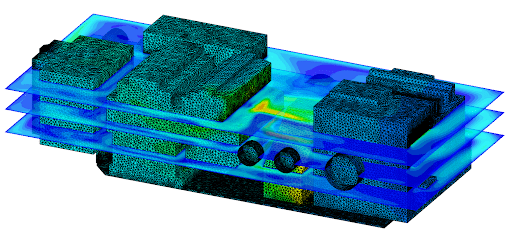

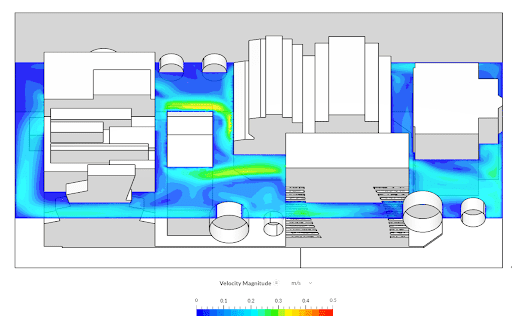

Submer evaluated five different cooling solutions within SimScale for this project using both the conjugate heat transfer (CHT) solver and the convective heat transfer solver. Both cases considered laminar flow, as the natural convection in the system does not generate excessively high velocities. Different sized and shaped heat sinks were optimized to take advantage of the flow profiles generated via natural convection allowing them to whisk away more heat with the same flow. By duplicating the previous simulations and using them as blueprints, Submer was quickly able to set up and run their different designs, limiting the time needed to generate their results.

Each simulation ran for 1000 iterations and took between 1.5 to 2.5 hours running off of 32 cores. By using particle tracers and animations, Submer was able to visualize and intuitively understand the convective currents within their system. This empowered their iterative design where new designs were taking advantage of the predicted flow profile. The performance of their cooling was evaluated via cutting planes with thermal contours, and iso-volumes based on temperature.

Submer has now involved SimScale in a variety of their R&D projects in order to design better solutions to their engineering challenges by evaluating more designs quickly and cheaply.

Sign up for SimScale

and start simulating now