Founded in 1972, Gruner Roschi AG is a leader in the construction industry in Switzerland. Gruner Roschi AG, as a part of Gruner AG, specializes in HVAC engineering and building performance simulation. With a team of 50 people located in Bern, they are working on many interdisciplinary projects, and their dedicated staff guarantee customized solutions for demanding building construction projects. To ensure high quality, building performance simulations such as computational fluid dynamics CFDs are becoming more and more important.

Gruner Roschi’s project involved creating a suitable classroom ventilation design for a newly constructed building. Working closely with the chief architect on the project, it was determined that the design needed to be cost-efficient, eco-friendly, and ultimately low-tech. This meant as little technical installation needed to be used as possible in the design.

This posed an interesting challenge, as it eliminated the possibility of a mechanical ventilation system that would be able to control the building climate as well as airflow. As the team at Gruner Roschi aimed to discover, create, and validate the best natural ventilation design possible to be implemented, they turned to online simulation.

We decided to incorporate SimScale into our workflow based on the platform user-friendliness, no hardware requirements, affordable price, and incredible customer support. These were the key factors we were looking for when initially looking for simulation software, and SimScale combined, and exceeded all of our expectations.

Mario Flühmann

Member of Executive Board

As a first step, the team simplified a Revit model of the original building and focused on one classroom with several different window designs and room heating strategies. The team wanted to understand how the different designs affected the natural ventilation of the space, through the different window openings in the classroom. The goal was to test multiple designs, and then choose the best design to be implemented for construction.

Once in the SimScale platform, they used transient convective heat transfer simulation to evaluate four design versions. The team at Gruner Roschi initially found it difficult to strike the right balance between the level of detailing in the CAD, and obtaining the coarsest mesh without compromising on the accuracy of the results, hence keeping the simulation time as less as possible. One factor that helped to find the best balance between mesh, accuracy, and time was being able to run dozens of mesh variants and simulations in parallel.

For each design variant, 5-10 simulations were ran using different meshes and settings. The simulation runtime varied between 8 and 17 hours with a usage of 8 to 32 cores.

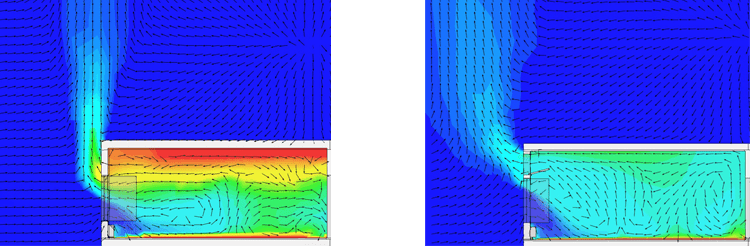

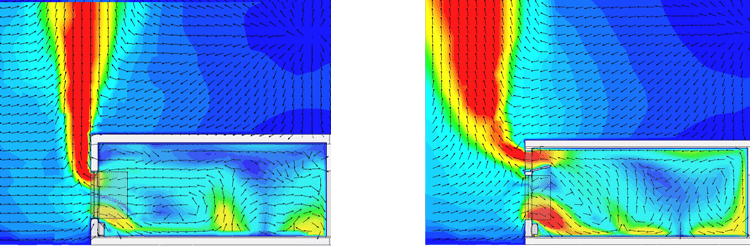

The team simulated the winter case for each design, with an outside air temperature of -5°C and the room air temperature at 21°C. After the simulation, they took a closer look at a time frame of 300 seconds in time steps of 30 seconds. The simulation results showed, in each time step, what occurred when the window of the schoolroom opened and cold air from the outside flowed through the space.

Finally, the simulation showed that the two different heating systems (convectors or floor-heating) hardly had any influence on the incoming flow. Instead, it was found that the type of window design in the separate simulations made a bigger difference in terms of air exchange. With this insight, Gruner Roschi could clearly see from the results that the variant with the tilted upper windows allowed for better airflow, and thus, better ventilation.

Working with SimScale gave us the possibility to inspect which of the architectural and technical solutions works the best way and give us certainty about our decisions. One other big factor is the speed in which SimScale can deliver results, through its great parallelization capacity. Without SimScale, we wouldn't be able to deliver high-quality results in the required time period.

David Akeret

VDC Specialist

The chosen design variant for the classroom will be utilized, and will come to fruition in about two years when the building is completely constructed. As for Gruner Roschi and SimScale, more collaborations and projects to come!

Sign up for SimScale

and start simulating now