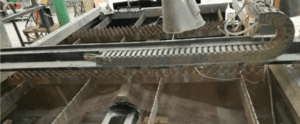

The construction of industrial ovens is an extremely complex task that requires innovative and dedicated solutions for end-customer applications. The main goal is to ensure a uniform air temperature at the part level in the conveyor or furnace. This is achieved by choosing the correct furnace size, heating type and speed of internal fans. Furnace Fixers’ products allow meeting quality specifications for heat treatment such as AMS-2750E or CQI-9. Specifically, the ovens used to make parts need to provide a uniform temperature within a plus or minus range from the set point, within an area of the oven designated as the work zone. The greater the size of the work zone, the better. In this case, the range they were concerned with is plus or minus 20⁰F.

Although general solutions can be replicated between projects, in many cases these changes drive the development into uncharted territories. The vast experience of Furnace Fixers’ team allows them to estimate the required parameters of constructed furnaces with a good accuracy. Unfortunately, non-standard specifications of one particular project led to the underestimation of the required fan performance. This resulted in the need of the company to rebuild the furnace. As a result of this misperformance, Furnace Fixer’s team decided to use numerical testing of their machinery before it would be constructed.

The CAD tools that were in use at the company had CFD capabilities, but they did not provide the expected results. Moreover, the steep learning curve made it extremely difficult to gain sufficient knowledge of engineering simulation to become independent from external support. With a new, non-standard project on the horizon, which involved a furnace with a very wide opening, a different approach was needed. This is when Furnace Fixers decided to use SimScale.

As a small company, we were reluctant to try engineering simulation. We assumed that setting up and interpreting a simulation of airflow and temperature would be beyond our capability. However the assistance provided by SimScale and specifically Dr. Pawel Sosnowski allowed us to get meaningful results in a couple of weeks. It didn't hurt that we didn't need a high-end computer dedicated to simulations either.

Craig LaMotte

Engineer at Furnace Fixers

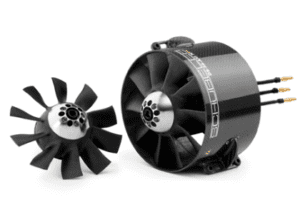

Having a wide-opening furnace would imply increased air circulation inside. The reference solution proposed the use of two fans with the blades diameter of 10 inches. To match the required performance, the team acknowledged that another fan might be needed and/or the diameter of the fan blades might need to be increased to 12 inches. Such modifications needed to be proven by a reliable source. This is where CFD simulations were to be put to the test.

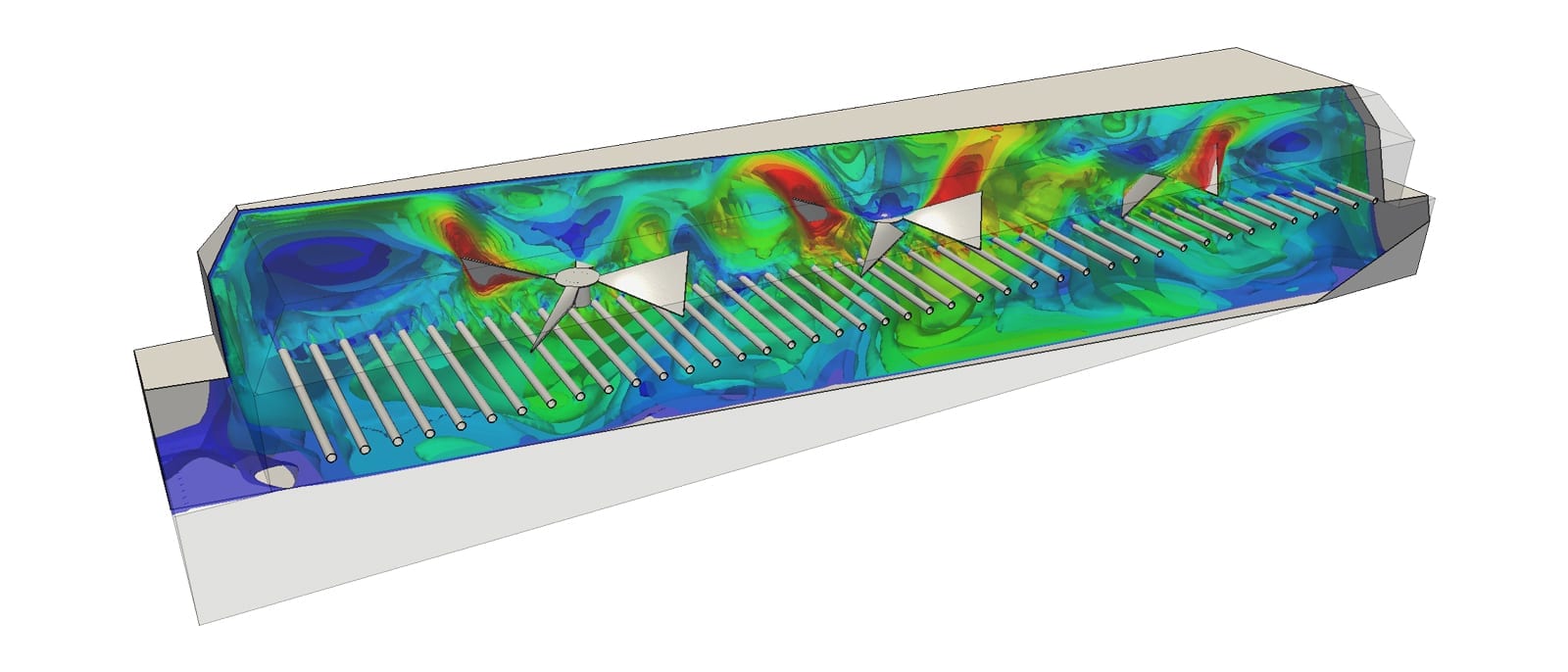

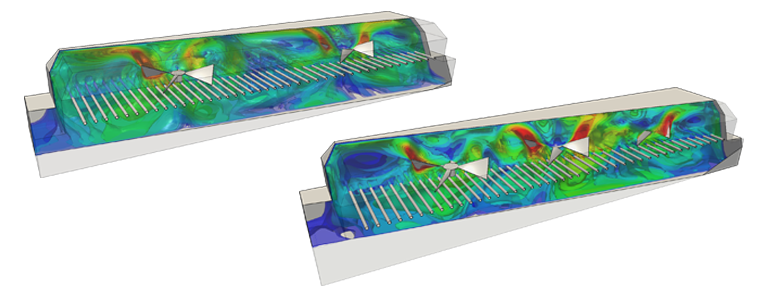

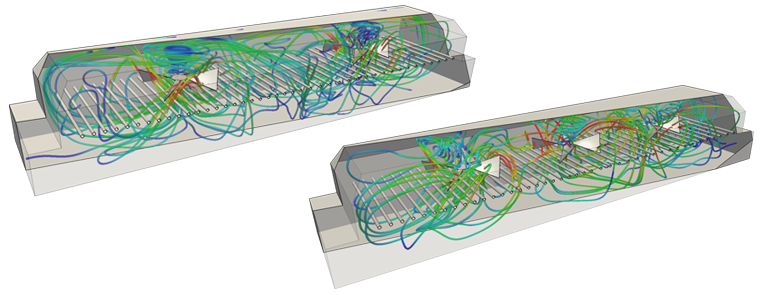

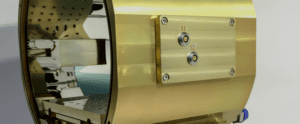

The first step of the CAE approach was to prepare a simulation of the reference furnace setup. With SimScale’s training materials and the help from the customer success team, the project moved forward swiftly and without major issues. This was possible despite a lack of previous experience of Furnace Fixers’ team with CFD. The assembly drawings of the furnaces were converged to clean volume extracts and imported to the platform in STEP formats. The complexity of the geometry required the use of parametric hexahedral meshes. The process of generating reliable volume discretization was prepared in collaboration with the SimScale team.

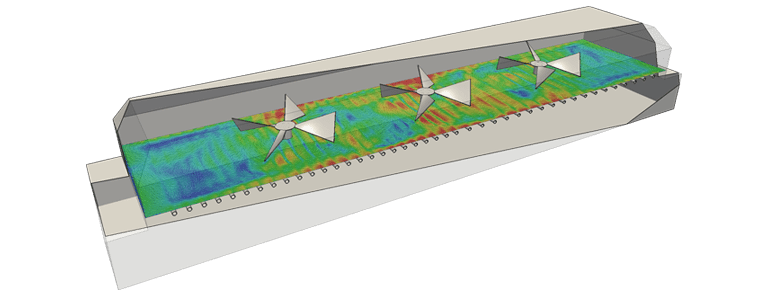

The main factor that determines the temperature near the furnace’s conveyor is the air speed. For this reason, the initial analyses were focused on calculating the air flow patterns within the machinery. The simulations were carried out on two furnace configurations, with 2 or 3 fans. Each configuration investigated the use of 10’’ or 12’’ fan diameters. Moreover, the analysis checked the performance of the air distribution at different rotation speeds and rotation directions of the fans.

Overall, 16 simulations with multiple runs were performed. They totaled in using over 1,200 computational core hours. As SimScale is a cloud-based CAE platform, the studies were carried out in parallel (usually 4 runs at once). This was an additional benefit for Furnace Fixer’s team in choosing SimScale. The results arrived much faster and the customer did not have to buy an expensive, powerful computer to carry out the analyses.

Thanks to the numerical simulations of the wide-opening furnace design carried out with the SimScale platform, Furnace Fixers’ team confirmed and validated the need to use three fans and 12’’ blades for the project. The constructed furnace exceeded the expected performance by 40%. The certainty during manufacturing phase that the oven will not need to be rebuilt made the purchase of a yearly SimScale Professional plan worth it. Moreover, with an extra subscription time left, there is a high potential of gaining insight into other designs as well.

This project helped our customer prove the value of using simulation in furnace design and establish a repeatable workflow for new projects to come. A future use of SimScale at Furnace Fixers will involve the analysis of upcoming projects as well as the investigation of existing designs for potential improvements and optimizations.

Thanks to the numerical simulations of the wide-opening furnace carried out with the SimScale platform, Furnace Fixers’ team confirmed and validated the need to use three fans and 12’’ blades for the project. The constructed furnace exceeded the expected performance by 40%.

Sign up for SimScale

and start simulating now