As the automotive industry races towards innovation and efficiency, the role of engineering simulation becomes increasingly crucial, especially to the design process. Yet, amidst the push for progress, automotive suppliers may raise concerns when presented with new simulation tools and solutions. These objections, while valid, often stem from misconceptions or concerns about compatibility, efficacy, and security.

Here, we explore the top five objections raised by automotive suppliers and provide evidence-backed responses to demonstrate how the SimScale cloud-native simulation platform not only addresses these concerns but exceeds expectations.

1. “It doesn’t work with the existing simulation tool landscape.”

Compatibility is paramount in adopting any new technology, particularly in an industry as interconnected as automotive manufacturing. Many suppliers hesitate to embrace new simulation platforms for fear of disrupting their existing tool landscape. However, SimScale is designed with interoperability in mind. Its cloud-native architecture allows seamless integration with a wide range of existing design and simulation tools, ensuring a smooth transition without the need for costly retooling or data migration.

Moreover, SimScale’s support for industry-standard file formats such as STEP, IGES, and STL ensures compatibility with CAD software commonly used in automotive design. Whether suppliers utilize CATIA, Siemens NX, or SolidWorks, SimScale seamlessly interfaces with these tools, enabling engineers to leverage existing designs and workflows without friction.

Furthermore, SimScale offers extensive support and documentation for integration, along with dedicated technical assistance to facilitate a hassle-free onboarding process. By embracing SimScale, automotive suppliers can enhance their simulation capabilities without disrupting their existing tool landscape, thereby maximizing efficiency and minimizing operational friction.

For more information about SimScale’s integrations and proven workflows, check out our Integrations & Partners page.

2. “We don’t really believe in designers simulating.”

Traditionally, simulation has been viewed as the domain of specialized analysts rather than designers. This is because legacy simulation tools tend to be intricate and time-consuming, given that they are designed for dedicated simulation experts. However, this perception is rapidly evolving as automotive suppliers seek to accelerate innovation and streamline product development. The design cycle is getting shorter as suppliers seek faster design output that meets the increasing OEM demand and the stringent government and industry regulations. As a result, simulation lead time has become an impeding bottleneck for auto suppliers.

Transforming the design cycle by enabling simulation early in and across the whole design process is how suppliers can resolve this bottleneck. This not only involves but also promotes designers simulating their design iterations as early as possible, allowing for faster, more informed decision-making. SimScale empowers designers by providing intuitive simulation tools that seamlessly integrate into their existing CAD environment.

With SimScale, designers can validate their concepts early in the design process, identifying potential issues and optimizing performance without relying solely on iterative physical prototyping or waiting days and weeks for validation from the simulation team. The platform’s user-friendly interface and extensive library of simulation templates enable designers to quickly set up and run simulations in parallel, gaining valuable insights into product behavior and performance that can inform their design decisions on the spot.

Moreover, SimScale offers comprehensive training and support resources tailored to designers, ensuring they have the knowledge and tools necessary to leverage simulation effectively in their workflow. By democratizing simulation and empowering designers, SimScale enables automotive suppliers to unlock new levels of innovation and efficiency, driving competitive advantage in a rapidly evolving market.

3. “We already do simulation.”

It’s not uncommon for automotive suppliers to already have simulation practices in place. However, the question arises: How does SimScale differentiate itself in a landscape where simulation is already prevalent?

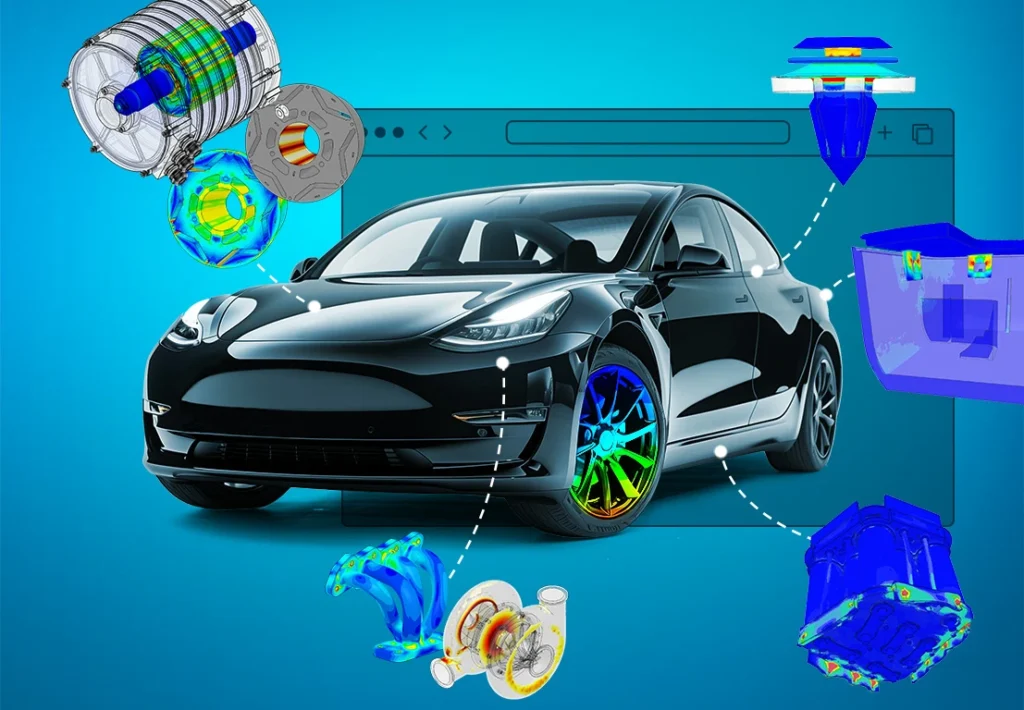

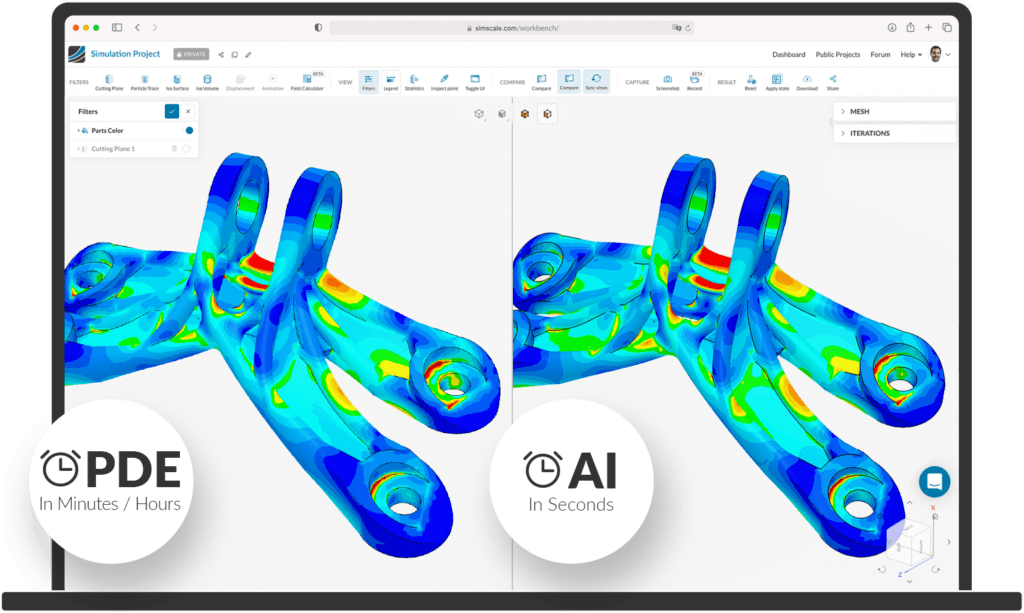

SimScale goes beyond traditional simulation software by offering a cloud-native platform that eliminates the need for costly hardware investments and maintenance. With SimScale, automotive suppliers can leverage the power of the cloud to scale their simulation capabilities dynamically, accommodating fluctuations in demand and workload without incurring additional infrastructure costs. They can ensure an enterprise-wide simulation deployment while maintaining simulation quality control with the expert simulation team. This frees simulation from any local hardware limitations, making it an underlying solution across the whole design cycle. From AI-powered, cloud-hosted, real-time simulation analysis to relatively infinite scalability thanks to parallel simulation at any scale, SimScale enables unprecedented design space exploration.

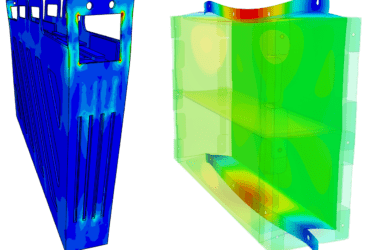

Furthermore, SimScale’s breadth of simulation capabilities extends beyond traditional finite element analysis (FEA) and computational fluid dynamics (CFD). From structural analysis to thermal simulation, fluid flow analysis, electromagnetics, and multiphysics simulations, SimScale offers a comprehensive suite of simulation tools to address diverse engineering challenges in automotive design and manufacturing.

Additionally, SimScale’s collaborative features facilitate seamless communication and knowledge sharing among team members anywhere in the world at the click of a button, enabling interdisciplinary collaboration and accelerating decision-making processes. With SimScale, automotive suppliers can augment their existing simulation practices with cutting-edge technology, company-wide deployment, and broad application coverage, enhancing productivity and driving innovation across the organization.

4. “The OEMs dictate which tool we need to use.”

The influence of OEMs on the tool selection process is undeniable in the automotive supply chain. Many suppliers feel constrained by OEM mandates, leading to a reluctance to explore alternative simulation platforms. However, it’s essential to recognize that SimScale offers unique advantages that align with the goals of both suppliers and OEMs.

Firstly, SimScale’s cloud-native architecture ensures seamless collaboration and data exchange between suppliers and OEMs, facilitating streamlined communication and workflow integration. By adopting SimScale, suppliers can demonstrate their commitment to innovation and efficiency, potentially enhancing their standing with OEM partners.

Moreover, SimScale’s extensive library of simulation templates and pre-configured workflows aligns with industry best practices and standards, ensuring compatibility and compliance with OEM requirements. Whether it’s crashworthiness analysis, aerodynamic optimization, electromagnetics, or thermal management, SimScale provides the tools and expertise necessary to meet and exceed OEM expectations.

By leveraging SimScale, automotive suppliers can differentiate themselves in a competitive market while simultaneously aligning with the strategic objectives of OEM partners. Rather than viewing OEM mandates as constraints, suppliers can embrace SimScale as a catalyst for innovation and collaboration, driving mutual success for both themselves and their OEM partners in this highly competitive and demanding industry.

5. “Cloud security issues are the problem.”

Security concerns often top the list of objections automotive suppliers raise when considering cloud-based solutions. However, it’s crucial to recognize that SimScale takes a proactive approach to address these concerns, ensuring the highest standards of data security and compliance.

SimScale is committed to protecting customer data through robust encryption protocols, access controls, and regular security audits. With its encryption protocols, SimScale protects customer data both in transit and at rest. The platform also adheres to industry-leading standards such as SOC 2 Type II, providing assurance to automotive suppliers regarding their data’s confidentiality, integrity, and availability. SimScale assures automotive suppliers that their data is handled according to industry-specific security requirements. By providing choice and flexibility, SimScale empowers automotive suppliers to leverage cloud-based simulation without compromising security or compliance.

For more information, visit SimScale’s security page or contact us. We can answer any questions you might have about data security.

Conclusion

While automotive suppliers’ objections regarding compatibility, efficacy, and security are understandable, SimScale offers compelling solutions backed by evidence and expertise. By addressing these concerns head-on and demonstrating the tangible benefits of cloud-native engineering simulation, SimScale enables automotive suppliers to embrace innovation, drive efficiency, and stay ahead in a rapidly evolving industry.