A few decades ago, aerospace became the first industry to embrace engineering simulation. From nanotechnologies and micro-composite materials to futuristic wings profiles, many research projects in aircraft design focus on finding better solutions and bringing them to market faster, while simultaneously reducing costs.

Using engineering simulation software as part of their development process, aerospace companies and engineers can evaluate different designs earlier in the development process. This streamlines the design process by reducing the number of required physical prototypes.

SimScale provides the opportunity to simulate and test designs completely in the web browser, giving access to all analysis capabilities and collaboration options. As a cloud-based CAE platform, SimScale makes it possible to perform powerful CFD simulations or FEA from any device.

Here are a few CFD software simulations related to the aerospace industry from the SimScale Public Projects Library, which engineers can copy and use as templates for their own CFD analyses of different aircraft systems and components.

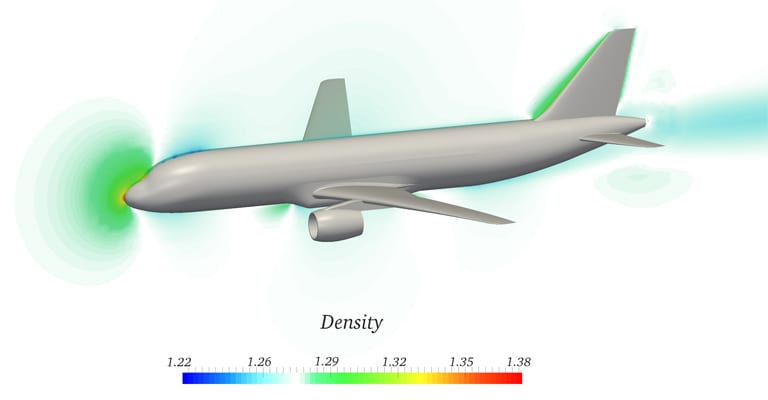

Aircraft Design Aircraft Design Aerodynamics Analysis

This aircraft simulation shows the airflow distribution around an aircraft design at low subsonic compressible flow regime. The project was used in the Aerospace Workshop featuring EUROAVIA organized by SimScale, which you can watch immediately by filling out this form.

The flow of air around the commercial aircraft model was simulated via the Reynolds-averaged Navier-Stokes (RANS) method. The flow conditions were Mach number M = 0.35, Angle of Attack = 2 degrees, Pressure P = 100000 pa and temperature T = 0 degrees Celsius. For turbulence modeling, the k-omega SST model was used with the wall function approach. A ramping of the velocity boundary condition was applied up to the free stream value for better convergence.

If you want to try your own simulation project, see our step-by-step tutorial on how to set up and perform this analysis.

Aircraft Simulation Aircraft Landing Gear CFD Analysis

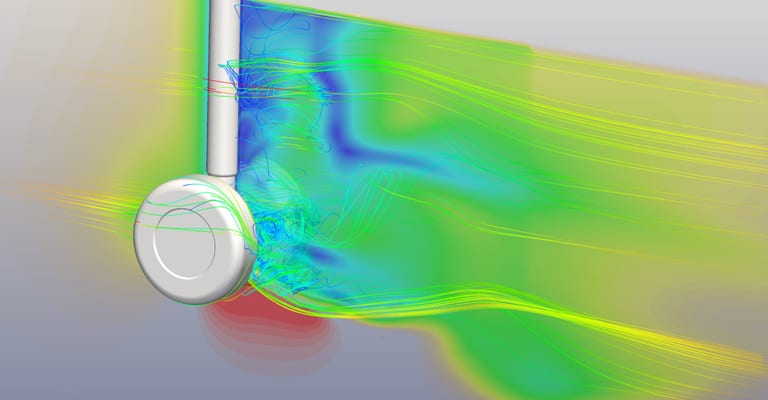

CFD simulation of a landing gear carried out with SimScale

This landing gear simulation shows how SimScale can be used for an airflow analysis around an aircraft landing gear. Landing gears are among the most critical components of an aircraft. During take-off and landing operations, the wheels can cause problems that may affect the safety and security of the plane and passengers.

In this airflow analysis, the large eddy simulation (LES) method was used. The geometry is a simplified version of a common front landing gear configuration for any commercial aircraft. The free stream flow velocity was 35m/s under standard conditions. A ramping of the velocity boundary condition was applied to gradually increase the velocity from a low value to the free stream value for faster convergence. The simulation investigates the instantaneous velocity profiles and the wake vortices. The CFD simulation results give an insight into the flow field in the wake regions.

Aircraft Design Optimization Optimization of a Wing with CFD Simulations

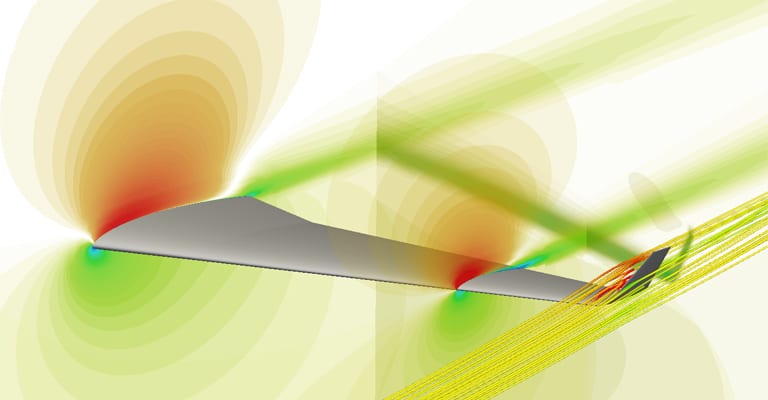

Aircraft wing simulation with SimScale

The shape and positioning of the wings are what determines the efficiency of an airplane in flight.

This project simulates two designs of aircraft wings and their aerodynamic effects. This project was also a homework exercise for the SimScale Aerospace Workshop – Session 2. This exercise involves simulating the aircraft wing with applied bending and torsional load due to wind pressure.

The task requires the user to set up six different configurations with three different models and compare the results. Its purpose is to demonstrate how the deformation and stresses change with each structural optimization of a wing. The figure shows the possible load configurations with the initial model.

Aircraft Wingtip Design Wingtip Vortices Simulation

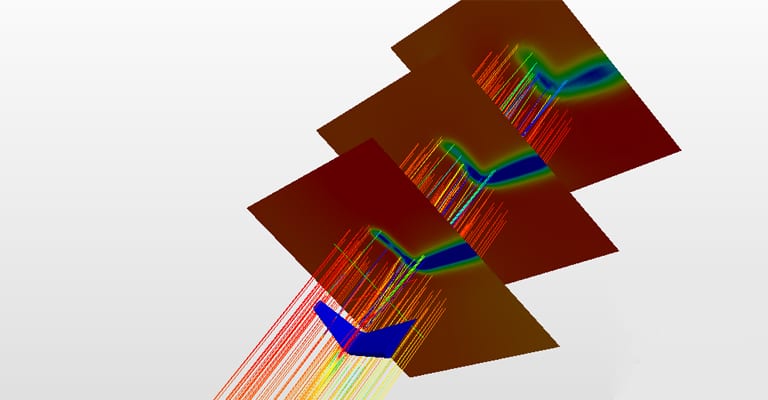

Velocity field for a wing with winglet

A span-wise difference in lift generation creates wingtip vortices. These vortices cause a destabilization and loss of performance in the form of a reduction in lift. This project demonstrated that winglets could be the best solution and an effective measure to reduce the strength of wingtip vortices.

The simulation investigated the velocity fields in two parallel models, for a wing with and without a wingtip attachment. The simulation clearly demonstrated losses of performance in the model without a wingtip attachment. This was due to the vortices that reduce the lift effect on the wing.

In the second model, wings with winglets generate larger lift than those without, when all other parameters are the same.

Aircraft Design Aircraft Cabin Ventilation

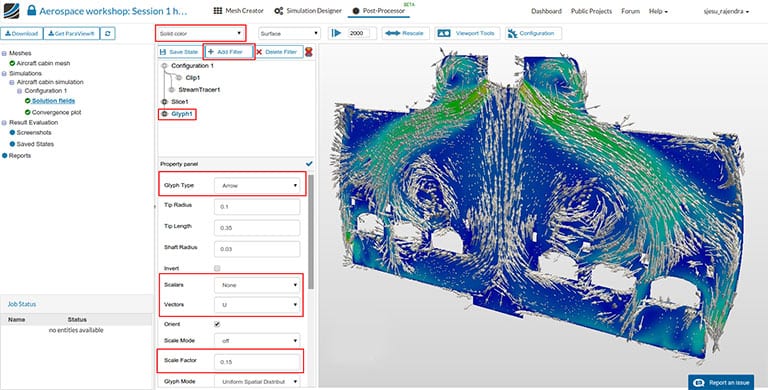

CFD analysis of the ventilation inside an aircraft cabin with SimScale

The aircraft ventilation system is essential for passengers’ comfort. Here is a project that simulates the airflow inside an aircraft cabin.

This CFD analysis shows two cabin configurations and their effect on the airflow pattern. It initially involves a ventilation simulation in an aircraft cabin. To find the best solution, six alternative configurations of inlet and outlet are investigated.

This project was also used in the SimScale Aerospace Workshop. Watch the recordings for free.