Vebu is a fully integrated corporate innovation studio with a vision to automate the entire food supply chain. The ever-growing labor gap has broad implications for businesses and consumers alike and is only one of many problems that the industry faces, hence the imperative for automation. With expertise spanning robotics, hardware engineering, software solutions, and regulatory compliance, Vebu is the leader in food automation building best-in-class products and technology solutions.

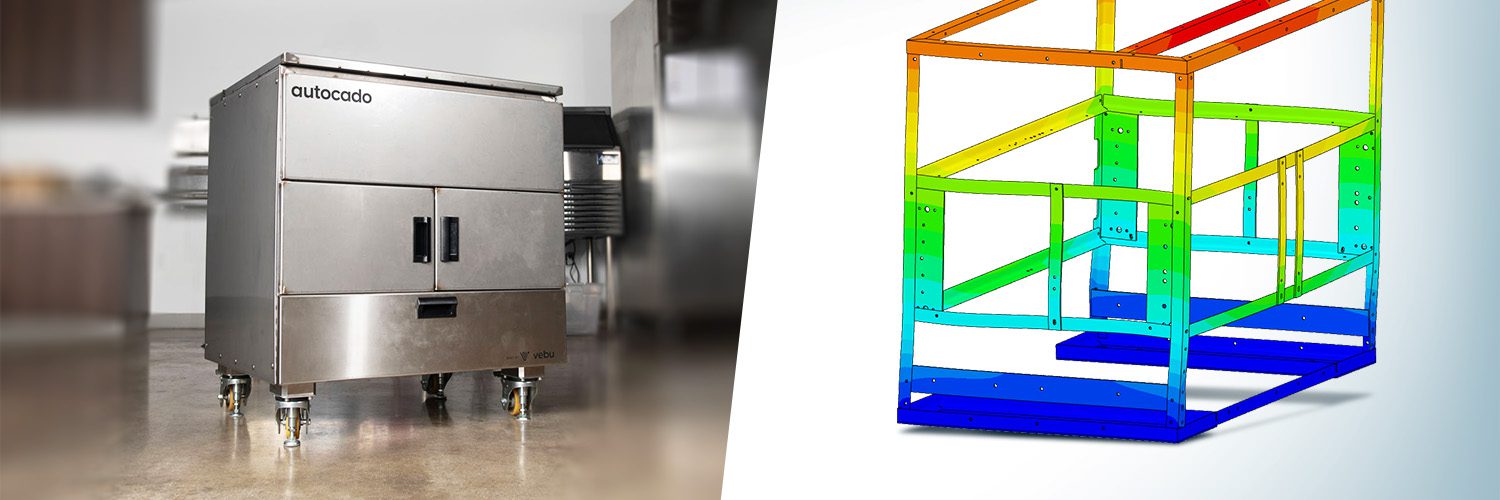

In partnership with Chipotle, Vebu has unveiled a new avocado processing bot called Autocado. This device automates the cutting, coring, and scooping of avocados before they are hand-mashed to create the restaurant’s signature guacamole. Autocado was designed and built to fully automate avocado processing. Chipotle crew members will simply load a case of avocados (~25 lbs) into the device and, less than 30 minutes later, remove a bowl of fresh avocado with pits and skins discarded. Vebu worked hand-in-hand with certified training managers from Chipotle to analyze the company’s preparation process and identify tasks that are time-consuming and less favorable among crew members.

Vebu’s novel robotic solution is projected to create big savings in Chipotle kitchens and eliminate repetitive tasks while maintaining the same quality customers expect, taking 50% less time to prepare guacamole, for example.

Vebu has revolutionized its food processing operations through the integration of advanced engineering simulations, specifically leveraging the capabilities of SimScale software.

Vebu faced the challenge of designing robust and durable robotics for continuous food processing operations. Ensuring structural integrity and managing vibrations in machinery were critical to prevent equipment failure and maintain operational efficiency, especially in their specialized avocado processing technology. To address these challenges, Vebu adopted SimScale, an all-cloud simulation software, which seamlessly integrated with their existing web-based 3D design tool, Onshape. This integration facilitated easy model exchanges and streamlined the design process.

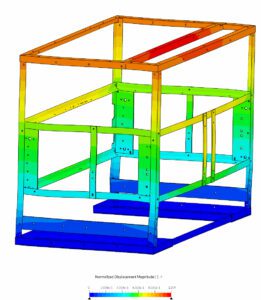

Vebu extensively utilized SimScale for various projects, primarily focusing on Finite Element Analysis (FEA) for static structural analysis. This approach allowed them to conduct a sanity check of their designs before incurring the costs of building physical prototypes. A notable application was in the design of uniframes for their equipment which would be subjected to heavy loads and vibrations/movement from machine operation.

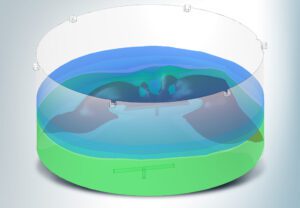

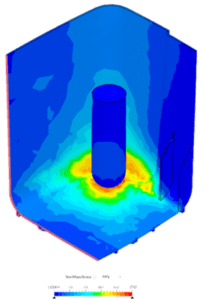

Recently, Vebu employed modal analysis to assess vibrations and predict deformations in their product structures. Using SimScale’s modal harmonic analysis, they successfully analyzed the vibration modes of various components, including those made of plastic and copper. This analysis was crucial in ensuring that their avocado processing technology operated safely and efficiently, without the risk of equipment failure due to vibrations. As the machines operate at high throughput and are in constant operation, the vibration and harmonic effects would lead to deformation over a prolonged period. Predicting displacement at key operating points and hence, modal frequencies is an accurate method to calculate this risk.

Modal analysis is important to ensure that the frame will be stiff enough and remain structurally sound under operation and transport conditions. We want to make sure that the vibration modes of the frame that the machine might experience will not cause failure. For example, the frequency modes at 20, 33, and 38 hz are all relatively low frequencies which would be experienced under transport conditions on the highway and we need to make sure the frame won’t fail when the machine is being shipped long distance. In the next iteration of the machine this analysis will be doubly important as we are going to be using a vibration feeder which will subject the machine to a 30 hz vibration during operation.

Blake Winner

Engineer at Vebu

The decision to switch to a cloud-based tool stack was driven by the need for seamless integration and collaboration. The switch to Onshape and SimScale supported Vebu’s distributed team structure, including members in the Philippines, facilitating efficient remote collaboration and model sharing.

Vebu’s experience with SimScale highlights the transformative impact of cloud-based simulation software in the field of food processing technology. By enabling efficient, accurate, and collaborative design processes, SimScale has not only enhanced Vebu’s operational capabilities but has also set a new standard in the industry for integrating engineering simulations into the design and development of advanced food processing robotics.

as run for 3 seconds. The subsonic analysis type has a more robust simulation due to the efficient body-fitted mesh and, with lesser dependence on the transient timestep. Smaller time steps from 0.00025 s to 0.005 s were evaluated in the transient simulation to evaluate accuracy without compromising on computational resources or time.

The benefits of using SimScale were manifold. The software provided a wide range of analysis types, enabling early-stage testing and rapid prototyping – essential for a fast-moving startup like Vebu. With new prototypes developed weekly, SimScale’s up-to-date and proven solvers were invaluable for quick verifications. The ease of setup and use was another significant advantage, especially considering the team’s previous experience with SolidWorks simulation tools.

Blake Winner

Engineer at Vebu

Sign up for SimScale

and start simulating now