JESA is an engineering solution company that provides design, engineering, project delivery, and asset management services. It delivers end-to-end innovative and sustainable solutions for industrial and urban advancement primarily focused in Africa. JESA’s expertise in integrating simulation into water and desalination projects positions it as a leader in delivering sustainable and innovative engineering solutions for Africa’s industrial and urban growth.

Mohamed Amine Rabitateddine is a Chief Process Engineer at JESA Group. His team is involved in desalination, wastewater treatment, water pipelines, and distribution network projects. The team is using SimScale, mainly the incompressible solver for steady-state monophasic simulations and the multipurpose solver for multiphase simulations. Advanced concepts such as MRF, Porous Media, and Momentum sources are often used to model real-world water and wastewater complex flows. CFD has been used successfully to perform an assessment of seawater pump intakes, phosphoric acid recirculation systems, static mixers, and tanks for a live project in Africa.

JESA was tasked with designing a tertiary treatment system at the outlet of an existing wastewater treatment plant. A key challenge was controlling the inlet flow rate with a buffer tank while avoiding oversizing the downstream treatment plant. The available site space imposed a significant constraint: traditional rectangular or circular tanks would not fit without compromising operational autonomy or efficiency. To address these challenges, JESA proposed an innovative solution—a triangular buffer tank with strategically placed baffles (V4) to enhance wastewater circulation. The engineering team identified several primary objectives they had to work around, namely:

A CAD model of the triangular tank was designed in AutoCAD and imported into SimScale.

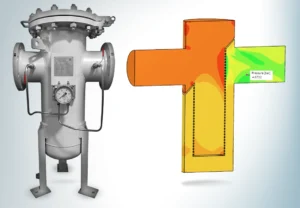

The incompressible solver was used for steady-state flow simulations with various baffle configurations, including baffle layouts (varying in number and length) that were simulated to identify the optimal configuration. The insights the team was looking to evaluate for each design include flow distribution and uniformity, absence of dead/circulation zones, and the mean age of water inside the tank.

SimScale’s cloud-based platform enabled simultaneous simulation of multiple configurations, significantly accelerating the evaluation process of critical project decisions. The images below show simulation results for the baseline case (V1) and a much improved near-final design (V4).

The best-performing baffle configuration (V4) avoided short-circuiting, reduced dead zones by 30% (Compared to V1), and lowered mean water (Fluid) age by 50% from 24 hours down to 11 hours. The final design required minimal material for baffles, reducing construction costs while meeting performance criteria. The triangular tank geometry maximized autonomy and operational efficiency within the limited site footprint, and the use of simulation clarified the final solution at an early stage and mitigated the risks of adopting an irregular shape for the tank.

Through the innovative use of CFD on SimScale, JESA successfully designed a cost-effective and efficient tertiary treatment system for a challenging wastewater project. The ability to simulate complex operating conditions and compare solutions at an early stage transformed the design process, ensuring optimal performance within uncommon physical constraints.

“SimScale provided detailed insights into flow behavior, allowing for a high degree of confidence in our design. The ability to troubleshoot potential issues at an early stage reduced the risk of operational inefficiencies and allowed for a data-driven comparison of design options, moving beyond traditional engineering rules of thumb. Being cloud-native enabled my team to set up, run, and analyze simulations anytime, anywhere, without hardware limitations, which is critical when working on continent-wide projects and travelling often. Sharing CFD results with clients easily strengthened their trust in JESA’s capabilities, leading to increased demand for CFD-based analysis, which we can use to scale up our activities.”

Mohamed Amine Rabitateddine

Chief Process Engineer at JESA Group

Sign up for SimScale

and start simulating now