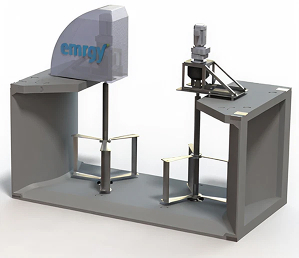

Emrgy is a recognized innovator in distributed hydropower, deploying modular hydrokinetic turbines in gravity-fed irrigation canals to generate clean electricity without disrupting water delivery. Their systems are tailored for infrastructure that already exists—avoiding the need for dams or diversions. Leveraging SimScale’s cloud-native CFD platform, Emrgy accelerates turbine innovation, validates site-specific deployments, and minimizes hydraulic impacts across a wide range of environments.

Emrgy’s hydrokinetic technology transforms clean energy production without traditional dams. Generating 5 to 25 kilowatts per turbine, this innovative approach harnesses flowing water’s energy, delivering reliable, cost-effective power while repurposing water channels for clean energy. Unlike conventional hydropower which requires gravity drop and head pressure for effective operation, Emrgy’s technology optimizes only on the kinetic energy or velocity of the volume of water flowing through a channel:

Designing vertical-axis turbines for non-disruptive canal installation presents a complex interplay of fluid dynamics challenges. Emrgy’s design goals extend beyond just maximizing power output, they must also minimize hydraulic disruption, maintain acceptable upstream water levels, and preserve flow conditions vital to irrigation system operators. A key challenge in deploying these systems is understanding both localized and large-scale hydrodynamic effects. Turbine performance must be assessed alongside system-wide variables such as surface elevation rise, changes in flow regime, and potential flood risk. For large-scale rollouts, the ability to rapidly evaluate feasibility and optimize turbine placement digitally is becoming mission-critical.

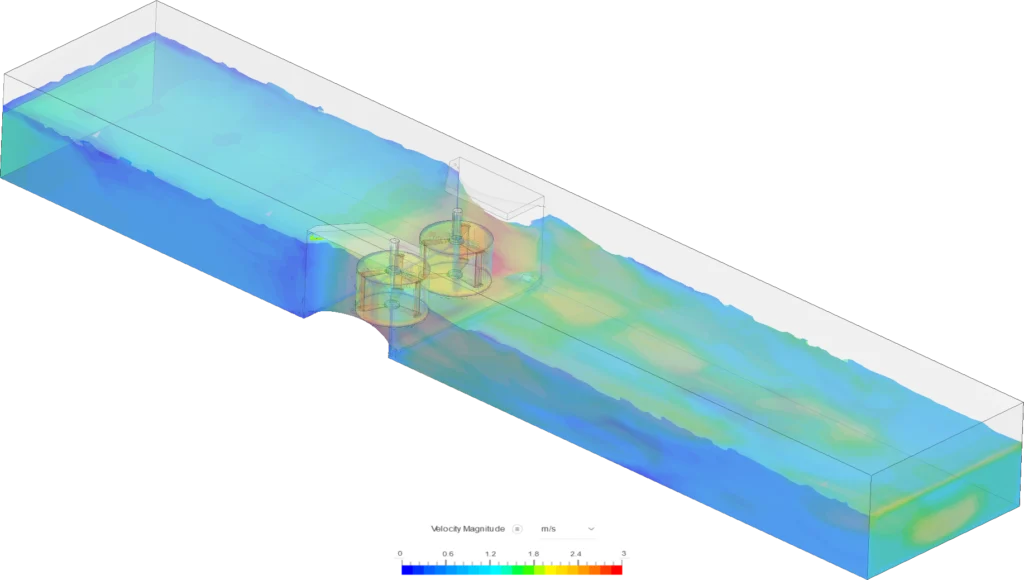

Dr. Alex Stubbs, a CFD expert with a PhD in Large Eddy Simulation and Emrgy’s lead fluid dynamics specialist, integrates SimScale’s Multi-Purpose CFD module into Emrgy’s daily design cycle. The team uses modeling to simulate free-surface flows and assess turbine impacts on canal water levels, flow acceleration, and hydraulic efficiency.

Being able to create a digital twin of essentially any given turbine installation is becoming increasingly critical. SimScale enables us to simulate entire systems at scale—enhancing performance, reducing risk, and unlocking deployment at speed.

Alex Stubbs

CFD Lead at Emrgy

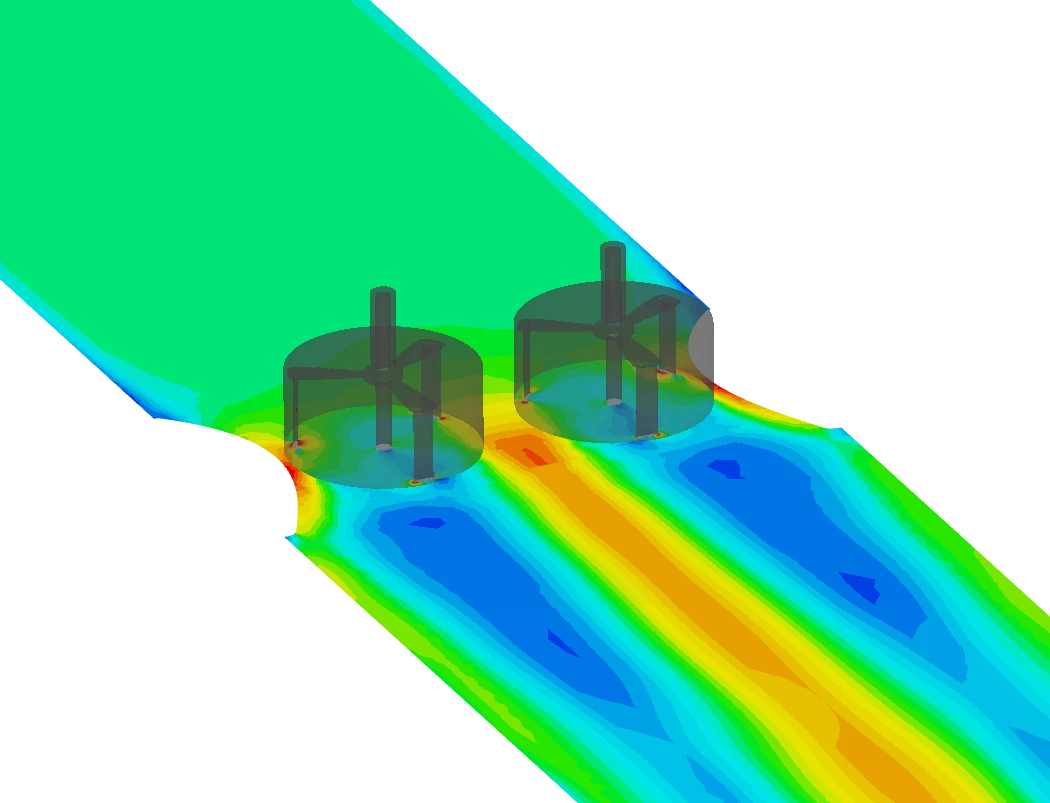

A representative project—the EM2.0 Twin model features a cross-section of two Emrgy turbines within a trapezoidal canal profile. Simulations track rotor RPM, flow velocity (1.0–1.5 m/s), and water surface deformation. The simulation model is used to evaluate:

Emrgy’s extensive use of SimScale allows it to go beyond generic hydro design and develop bespoke in-canal power solutions that coexist with irrigation infrastructure. The ability to model free-surface flow, rapidly assess turbine-canal interactions, and optimize layouts for both performance and hydraulic safety is transforming Emrgy’s design-to-deployment workflow including the following:

Flow simulation around an Emrgy vertical axis turbine:

Simply put, SimScale being cloud-based is more cost-effective. There are no hardware costs, and the flexible licensing is excellent, as it’s based on need rather than potential use. Using CFD in general to run through scenarios was historically a slow development cycle. Often, mechanical design development would outpace the simulation insights, which became the bottleneck. However, that’s changed. Now, it’s much faster and not limited by hardware. We can drive simulation insights into mechanical design and run five times the number of models at the same time compared to legacy systems. Development time is greatly reduced and aligns with mechanical, procurement, sales, and testing schedules. Scenario analysis can be performed instantly without needing to be scheduled.

John Tuttle

Chief Engineer at Emrgy

Sign up for SimScale

and start simulating now