Element Design works in partnership with Joel Gustafsson Engineers (JG Engineers) on a variety of projects dedicated to the energy transition toward a decarbonized urban environment. Element Design is an award-winning design and engineering consultancy dedicated to improving the value of projects for the built environment. Its team are experts in digital design for construction, using advanced ‘Fabrication / Building Integrated Modelling’ (FIM & BIM), and specialist Computational Fluid Dynamic (CFD) tools. JG Engineers is a leading building services, M&E, and design firm with expertise in a wide variety of environmental simulation, HVAC design, and planning.

Using SimScale, they have been able to successfully model the exact placement, sizing, and risk associated with deploying utility-scale air-source heat pumps (ASHP) in city centers, a core part of the decarbonization strategy for cities worldwide.

Feasibly integrating renewable energy centers powered by ASHP within the heart of urban environments is complicated. Finding optimal locations for these units, where they can operate efficiently without performance impacted by local sheltering buildings, poses a unique challenge.

One of the critical factors for the efficient operation of air source heat pumps is adequate air dispersion to ensure that the rejected air is effectively dispersed into the atmosphere. This positioning mitigates the risk of air recirculation and reduces the potential for pedestrian discomfort caused by cold air. Paired with the opportunity to use the underutilized roof levels, the heat pumps are less likely to be highly sheltered from surrounding buildings.

Sam Bromley, Founder and Design Director at Element Design, has expertise in simulating ASHP in city centers and has worked on large-scale projects in London where ASHP has been placed on rooftops and other locations. He has been using SimScale to simulate and visualize the heat and airflow from ASHP and how they interact with the local urban environment for the purposes of:

“As with all ASHP installations in dense urban environments, our job is to ensure good dispersion of rejected cold air into the ambient environment, reduce the risk of air recirculation, and provide confidence in the ASHP’s performance. Using SimScale to simulate these complex urban airflow interactions has been pivotal in proving their performance leading to project success and planning approvals.”

Sam Bromley

Founder and Design Lead at Element Design

Greenwich Peninsula ESCO Ltd, in partnership with Hemiko, has worked with the Greater London Authority (GLA) and the Royal Borough of Greenwich (RBG) to decarbonize the Greenwich Peninsula heat network. The Greenwich Peninsular Energy Center is an existing gas-powered energy center providing district heating to the local area in London. In an effort to decarbonize the heat production, the roof of the existing building has been earmarked for a large air source heat pump array. Element Design and JG Engineers’ involvement was to provide the mitigation of risks using SimScale.

This project will provide multiple benefits to the local community, including low-carbon heat, improved air quality, and accelerated decarbonization. It offers a cost-effective decarbonization option for nearby buildings, encourages further investment, and contributes to the proposed borough-wide heat network. The proposed ASHPs will offset the current gas-fired boilers and the combined heat and power (CHP) engine, significantly reducing gas combustion. Full adoption by existing connections is projected to offset over 90,000 tonnes of CO2 over 15 years, with the potential for further reductions.

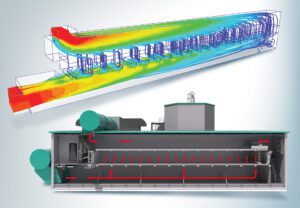

CFD simulations using SimScale were conducted to provide confidence to the client and planning authority that the proposed energy center would not pose a risk of cold discomfort and visible plumage that would be deemed unacceptable in the local community. CFD was also used to mitigate negative impacts such as pedestrian cold comfort, and adventitious sheltering of local buildings, ensuring proper dispersion into the atmosphere.

Suzanne from JG Engineers used OpenFOAM in SimScale. The team uses SolidWorks and Revit as their main CAD tools, both of which have native formats supported in SimScale. OpenFOAM is used for the combined thermal/airflow analysis. Both the large volume of air and heat need to be simulated for accuracy using prevailing wind conditions and ambient temperature and humidity. The key insights the team was looking for were as follows:

“We found using SimScale was a robust and accurate method to show confidence in the ASHP location and risk strategy. The SimScale software is easy to use yet powerful, with several integrated solvers that meet our needs. We are looking for wider microclimate analysis using SimScale in the future.”

Suzanne Goulder

CEng MIMechE is a Consulting Engineer at JGConsulting

Sign up for SimScale

and start simulating now