FFE Inc., a U.S.-based engineering and architectural firm, leverages simulation technology to improve the environmental performance of healthcare facilities. In one of their recent renovation projects—a kitchen modernization within a healthcare facility—the engineering team deployed SimScale’s cloud-native CFD platform to assess indoor air quality, exhaust dispersion, and the reentrainment risk of pollutants near exterior air intakes.

As part of this renovation, a complex interplay of interior and exterior air intake systems, multiple exhaust stacks, and nearby mechanical louvers presented significant IAQ and compliance challenges. The primary concern was to ensure exhaust contaminants such as carbon monoxide (CO) were not inadvertently pulled into air handling unit (AHU) intakes during operating scenarios.

Due to the nature of the reentrainment risk, the project has multiple issues to address at once using simulation:

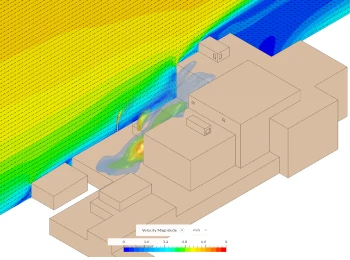

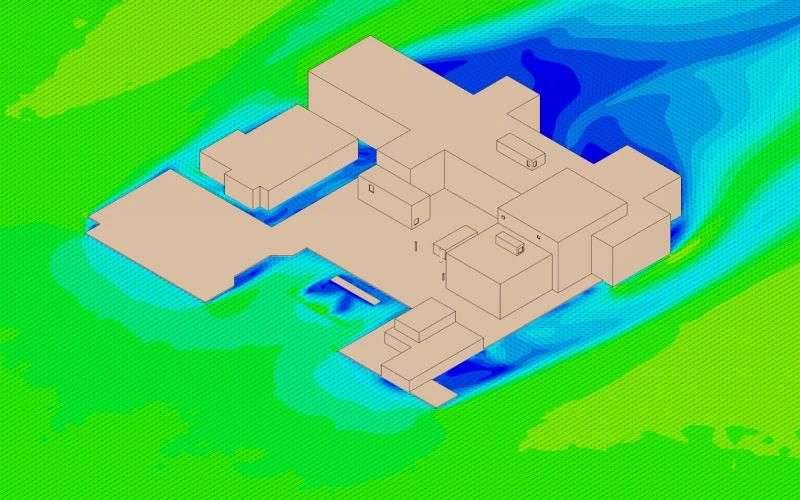

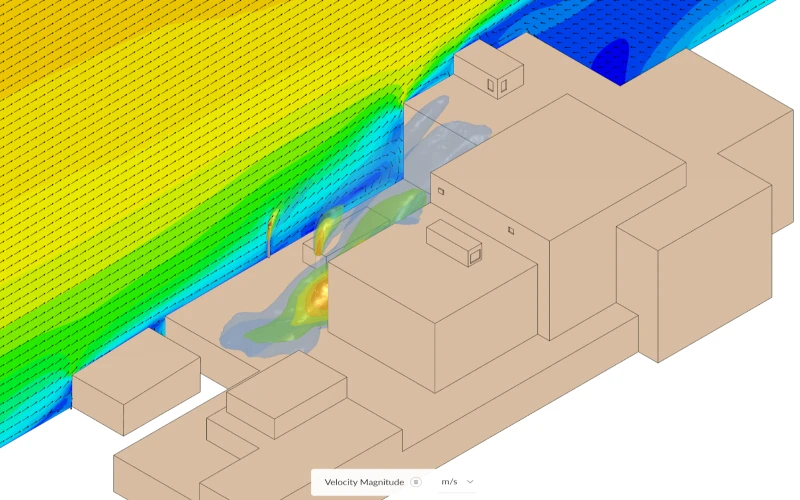

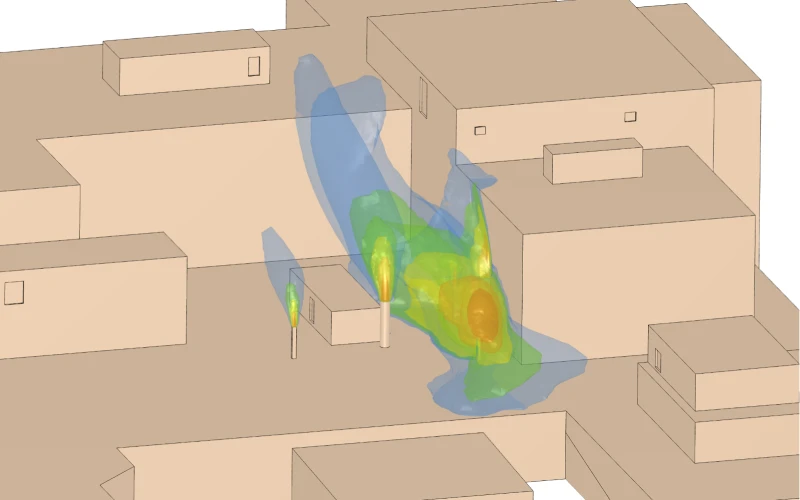

The engineering team exported the project geometry from Revit into STL format. Volumetric masses were defined to capture the facility’s intake louvers, exhaust stacks, and building envelope. Once imported into SimScale the Convective Heat Transfer solver (CHT v2) and passive scalar modeling with OpenFOAM were used to analyze airflow and contaminant distribution. External airflow simulations considered four wind directions and three wind speeds representative of regional meteorological data plus some correction from site data. CO and other pollutants were introduced using isovolumes to represent scalar density and visualize concentration plumes.

The simulations provided key visual and numerical validation for the project:

Using SimScale has enhanced our design work and our confidence in performing that work. Being able to run simulations quickly is valuable, and the fact that SimScale is cloud-based means that our office resources remain free for other tasks.

Ben Weinberger PE

Mechanical Engineer at FFE

FFE wanted to build an in-house CFD capability, while continuing to work with external consultants on specific projects. They found that SimScale’s cloud-based environment and intuitive workflow accelerated project delivery and enabled team collaboration, with the knowledge and experience gained also benefitting their work with 3rd parties.

The firm now considers simulation a core part of its HVAC and environmental design workflow, ensuring that both new and retrofit systems meet stringent IAQ, safety, and regulatory standards. Beyond this project, FFE has expanded the use of SimScale across additional HVAC upgrades including; boiler exhaust stack studies to evaluate thermal plume behavior and proximity to occupied zones; and diesel generator emissions modeling for assessing pollutant spread during emergency power events.

While we still work with external consultants for various projects, doing more in-house CFD modeling enables an even tighter integration between the design intent and the anticipated conditions.

Kyle Guggenheim

Mechanical Engineer at FFE

Sign up for SimScale

and start simulating now