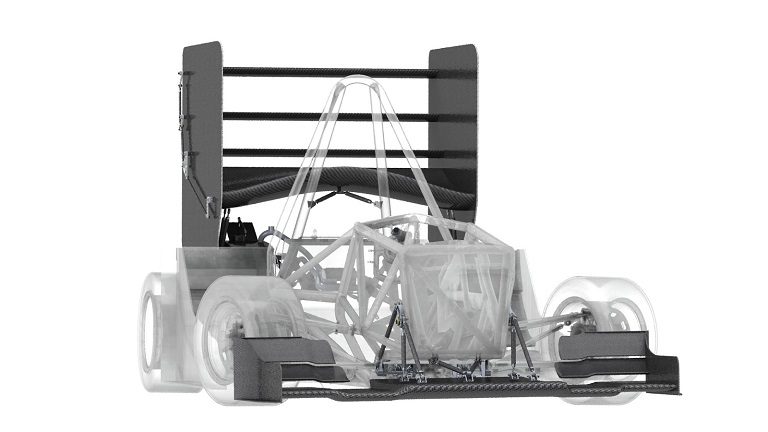

Sheffield Formula Racing (SFR) is the University of Sheffield’s Formula Student team. Formula Student is Europe’s most established engineering competition, which sees teams from over 100 universities across the world design, build, and race an open-wheel, single-seat race car. The competition is highly regarded by the motorsport industry as the transition for engineering students from academia to the workplace. The competition is made up of various static events (Cost, Business, and Design) and dynamic events (Acceleration, Skidpad, Autocross, Endurance, and Efficiency). SFR has been competing in the UK event (FSUK) at Silverstone Race Circuit annually since 2010.

SFR is among the UK’s top ten teams. It is made up of approximately 40-50 students from a variety of engineering disciplines including mechanical, aerospace, electrical, and materials. The team is run as a purely extra-curricular activity meaning the students invest a lot of their spare time to design and manufacture a new race every year.

Each year, their third-year mechanical engineering students engage in a semester-long group design project. The project aims at developing students’ teamwork and communication skills, as well as putting into practice the theory taught across their degree program. SFR typically proposes a number of future development projects for students to select from. These projects would typically be beyond the scope for the team to carry out in the normal design phase (September to December) and use the outcome of the project to gauge feasibility for future cars.

One of these projects in 2020 was to improve the track performance of the race car through aerodynamic development. Lap time simulation helped identify a drag reduction system (DRS) as one method to achieve this aim.

Part of the development of the DRS required the rear wing to be studied using computational fluid dynamic (CFD) tools. The team is familiar with CFD and has used it for numerous years to develop the current aerodynamic package. Traditionally, this would have been achieved using traditional on-premise simulation tools on the university campus. However, when lockdown struck in 2020, midway through the group design project, an alternative solution was needed.

“SimScale was approached so we could take advantage of their cloud-based computer-aided engineering (CAE) simulation package. SimScale allowed the team to complete simulations of the rear wing with 94 cores on their cloud application, using just their personal PCs. Not only did this mean a high amount of computing power could be utilized, but other work can be completed in parallel as the demand is not coming from the user’s device. The team found the software intuitive and simple to use and yielded good results,” says George Poulter, Chassis and Driver Environment Lead.

The simulations were based on the “Applications of CFD in Formula Student and Formula SAE” workshop sessions. The team found these workshops very clear, informative, and useful in setting up their own simulations.

The following procedure was used for the simulations:

- Incompressible flow analysis

- K-omega SST turbulence model

- Steady-state flow

- Air density = 1.225kg m-3 (density at sea level)

- Velocity inlet of 28m s-1 (estimated speed of the car at the end of a straight at FSUK)

- Fixed pressure outlet

- Slip wall condition applied to outboard wall and ceiling so no boundary layer is developed

- Symmetry condition on the centerline plane

- Moving wall condition on the floor at 28m s-1 so a non-zero surface velocity boundary layer is developed since the floor is moving relative to the wing

- No-slip wall condition on wing surfaces so a zero surface velocity boundary layer is developed

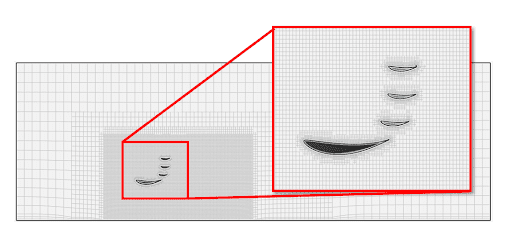

- Hex-dominant meshing algorithm

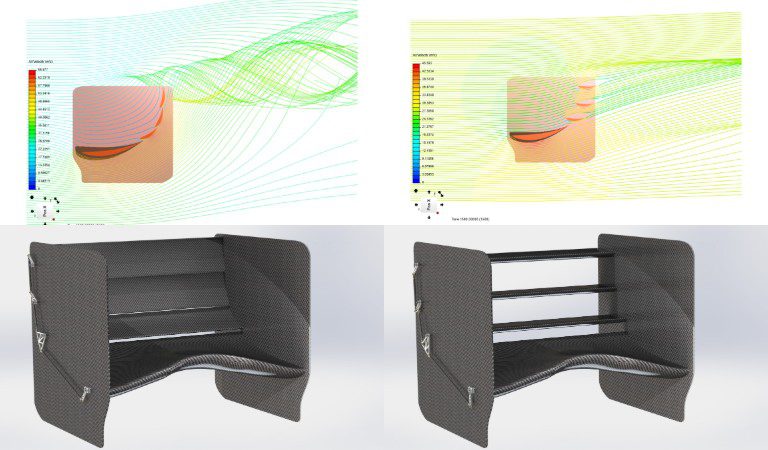

Simulations were run with the rear wing flaps in a “closed” and “open” configuration. Closed refers to a high angle of attack, whilst open refers to 0° angle of attack.

The Results

Meshing for each simulation took approximately 47 minutes (12.5CPUh). Simulation solving, for each simulation, took approximately 534 minutes (285.3CPUh). 94 cores were used.

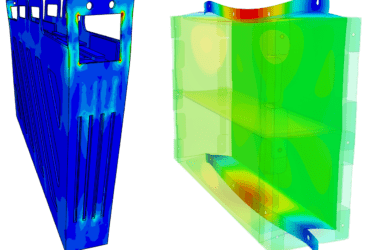

Velocity and pressure plots were studied to check for flow detachment on the rear elements. Forces and moments were also integrated across each of the elements, respectively, to determine how much downforce and drag changed across the configurations. These were also used for the structural design and analysis later on in the project. Table 1 summarizes the total downforce and drag across all rear wing elements in the “closed” and “open” configurations. Drag was found to reduce by 90%.

| Configuration | Total Downforce/ N | Total Drag/ N |

| Closed | 1101.84 | 565.77 |

| Open | 293.86 | 55.71 |

SFR found the software intuitive and simple to use and yielded good results. As mentioned, the workshops were also very helpful for first time users. SFR continues to use the software and hopes to expand its knowledge of the toolsets offered by SimScale.

Next Steps for Sheffield Formula Racing

SFR has been able to compute simulations while working from home during COVID restrictions where access to high specification computers is limited.

As the project did not have any form of validation, the next steps for SFR before they commit to installing the DRS would be to manufacture a prototype using experimental methods. This would include building a small-scale model to be studied in a wind tunnel. Hopefully, results can be correlated with the SimScale simulations and the set-up procedure adjusted where relevant.

Testimonial

George and the SFR team feel that Simscale offered a “simple-to-use and intuitive interface that showed promising results from the get-go. Their online tutorials and workshops were incredibly useful on getting up to speed with the software”.

Sheffield Formula Racing is a purely extra-curricular activity that is run by students. We wouldn’t be in the position we are today without the continuous support of our sponsor, SimScale.

George Poulter, Chassis and Driver Environment Lead