When geometry stops being drawn and starts being defined, design changes forever.

For decades, the language of design has been based on surfaces, sketches, and constraints.

Engineers have grown used to constructing geometry one step at a time – extruding, sweeping, or filleting to build models layer by layer.

But what happens when geometry is no longer described by a sequence of operations, but instead by mathematical fields and equations?

That’s the shift implicit geometry modeling brings. It’s not a new CAD feature or another incremental tool. It’s a fundamentally different way of thinking about how objects are created, changed, and optimized.

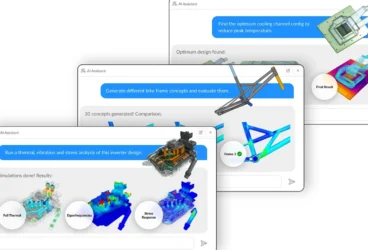

Even better, implicit modeling unlocks powerful opportunities to integrate with AI algorithms, enabling advanced shape and topology optimization.

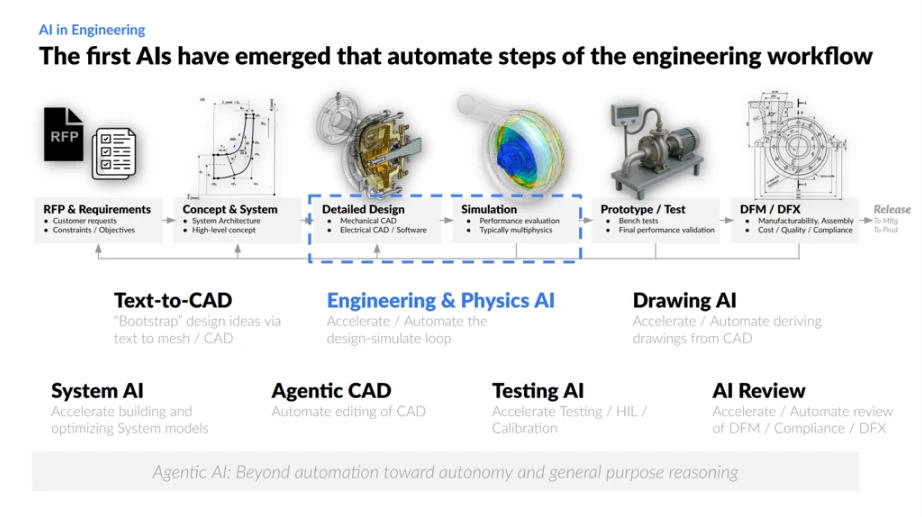

The changing landscape of design

Every product engineer knows the trade-off between creativity and control. Traditional parametric CAD excels at precision, repeatability, and manufacturability—but struggles with complexity and adaptability. The moment a design needs to evolve beyond its original constraints, the model often breaks. Surfaces fail to regenerate. Feature trees become tangled. Performance and hardware requirements add to the challenge. The geometry, instead of serving creativity, starts limiting it.

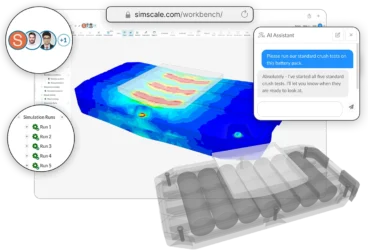

At the same time, AI simulation-driven design and optimization are moving to the center of product development. Engineers want to explore hundreds of design iterations, automatically test performance, and converge on the best possible shape.

Traditional CAD, built around static geometry, simply can’t keep up. Implicit modeling offers an answer.

What is implicit modeling?

Implicit geometry modeling represents 3D shapes using mathematical functions rather than explicit surface definitions.

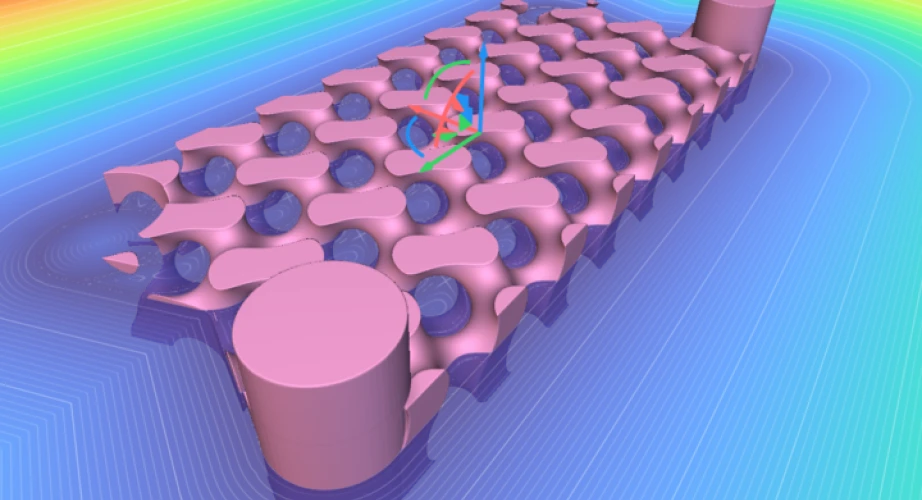

Instead of describing a solid by its boundaries (as in B-Rep or mesh-based systems), an implicit model defines a region of space where a function equals zero—the so-called implicit surface. This allows for smooth, continuous transitions, blending, and deformation at any scale without worrying about topology or feature dependencies.

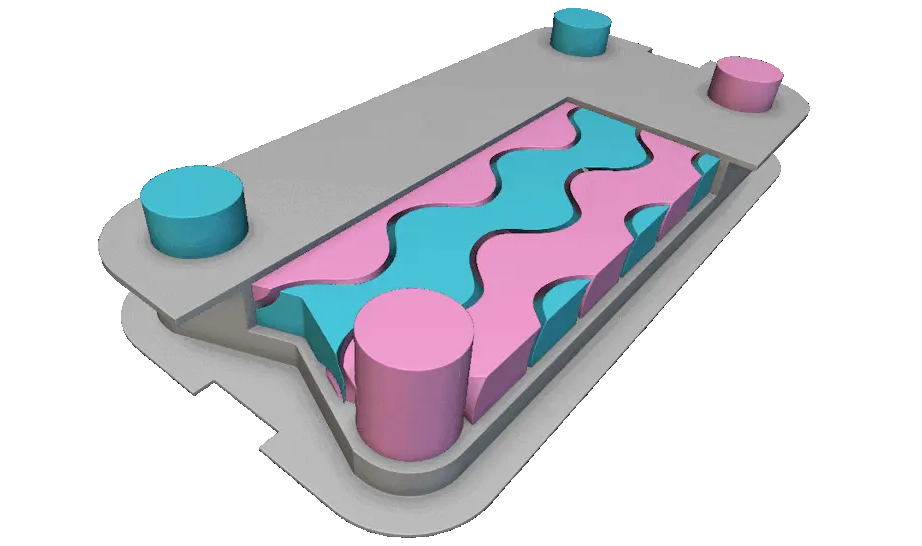

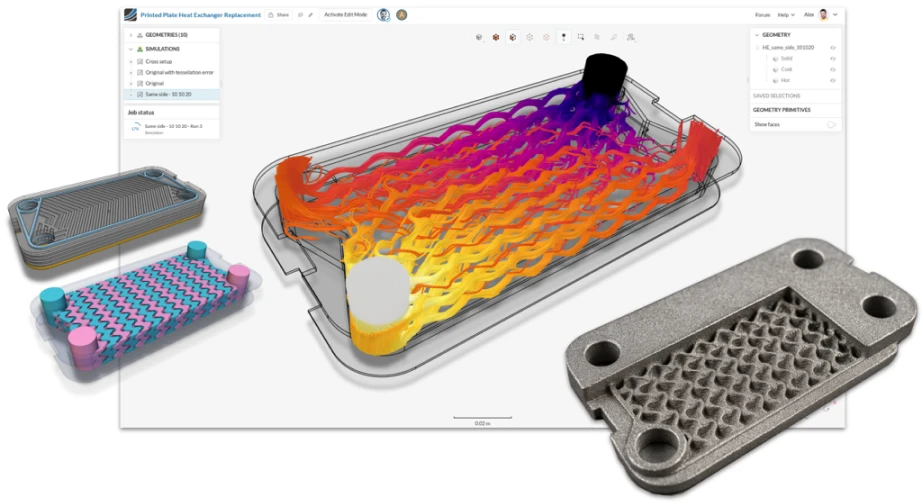

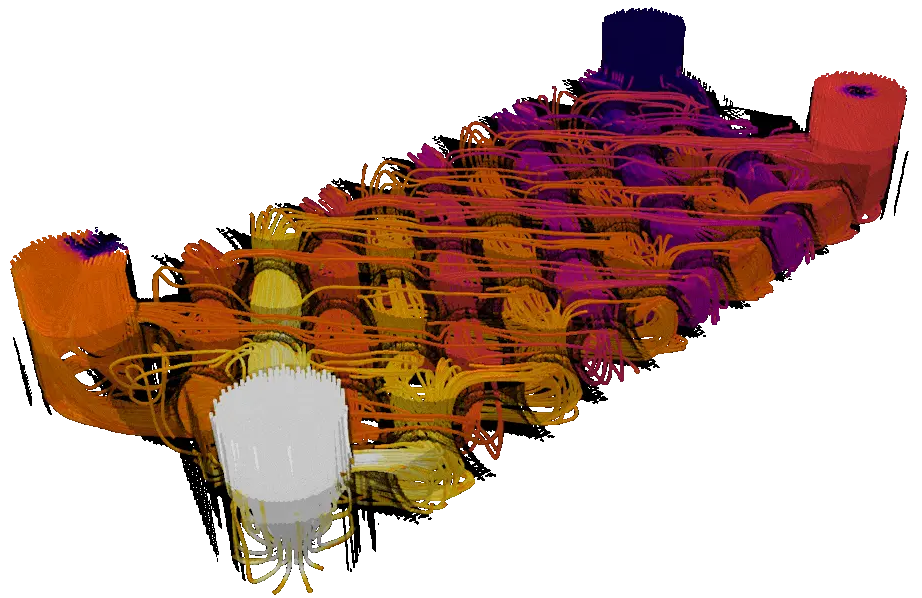

In practice, this means you can modify or combine complex geometries – like lattices, organic forms, or porous structures – using simple operations. Shapes can be added, subtracted, or morphed together using equations instead of manual CAD features. The result is a workflow that is more robust, more flexible, and dramatically faster when exploring non-traditional geometries.

Implicit vs. traditional modeling

To understand the impact, consider a typical CAD-based workflow.

- You start with sketches

- define constraints

- extrude features

- and trim surfaces.

Every change requires the system to recalculate dependencies. It’s precise, but fragile.

Now imagine instead defining the same geometry as a mathematical field. You can modify it globally – smooth transitions, blend regions, or adjust material density – without breaking any relationships.

This difference has huge implications for design automation and optimization. Implicit models can directly interface with algorithms that search, test, and evolve geometry automatically. They’re also inherently compatible with lattice generation, topology optimization, and generative design tools. Instead of trying to force simulation-ready meshes out of rigid CAD structures, implicit models create analysis-ready geometries by default.

Why now?

Several trends are converging to make implicit modeling more relevant than ever.

First, manufacturing is changing. Additive processes – such as metal 3D printing or high-resolution polymer fabrication—allow the production of complex, non-linear geometries that traditional CAD was never built to handle.

Second, computational power has caught up. With cloud-based platforms and GPU acceleration, implicit models can be calculated, visualized, and simulated in real time.

And third, simulation-driven design and AI-based optimization are entering everyday workflows. Engineers no longer design once and simulate later; they design through simulation. Implicit geometry provides the missing foundation for this level of integration.

Real engineering impact

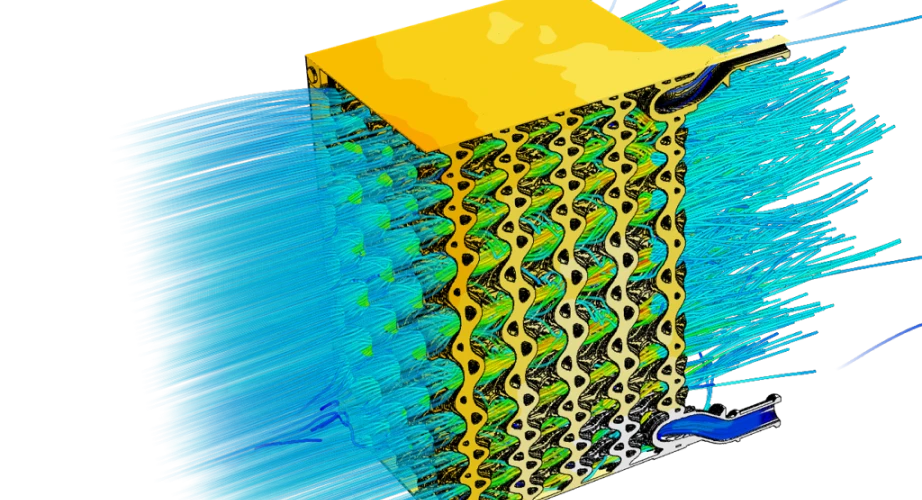

Implicit modeling isn’t just about generating futuristic shapes—it’s about solving real engineering challenges. Lightweighting, for instance, becomes more than removing material; it becomes a question of continuously varying density to match structural or thermal demands. Fluid flow optimization can be achieved by smoothly adjusting surfaces for better aerodynamics or cooling. Complex lattices can be embedded into structural components without manual feature management.

In fields like aerospace, medical devices, or consumer products, this approach means faster iteration, fewer redesigns, and products that are both lighter and stronger. The design space expands, while the time-to-simulation and time-to-market shrink.

The power of integration: Implicit + Simulation + AI

The real magic happens when implicit modeling connects directly with CAE simulation or AI-driven physics prediction.

Optimizing within the implicit space opens up massive opportunities. The feedback loop tightens. Designers no longer need to spend cumbersome work to rebuild and simplify models for each test or optimization cycle – changes are immediately updated in the field representation.

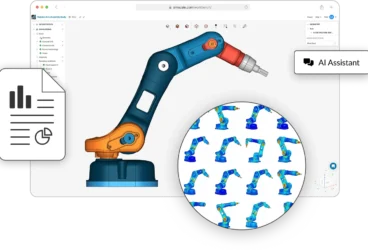

Powerful simulation technologies using meshless or quasi-meshless Cartesian techniques allow to directly evaluate the design without manual user input.

This synergy unlocks new frontiers for generative design, topology optimization, and AI-assisted shape exploration. Imagine defining not just a component, but an entire system, where materials, structures, and flows are optimized together, automatically, based on real physics.

The essential takeaways

Here’s what makes implicit modeling a quiet revolution in design engineering:

- Continuous geometry control – Modify shapes smoothly without constraint rebuilds or topology breaks

- Seamless integration with simulation – Connects directly with CAE and generative optimization workflows

- Ready for AI and automation – Enables algorithmic exploration and machine learning in design space

- Scalable complexity – Handle intricate lattices and organic structures efficiently

- Accelerated innovation – Iterate faster with fewer modeling bottlenecks and simulation-ready output

Looking ahead

Implicit modeling challenges a long-held belief in engineering: that geometry must be built piece by piece. As more tools adopt implicit representations, designers and engineers will find themselves working less with constraints and more with possibilities. Instead of fighting the model, they’ll collaborate with it—shaping, simulating, and refining in one continuous loop.

For design engineers, this is not just an efficiency gain; it’s a creative shift. It’s the ability to think in systems, not sketches. To design performance into geometry, rather than fitting geometry to performance. And as implicit modeling merges with AI-driven design, we’re seeing the emergence of a new era of computational creativity.

Ready to see how implicit modeling connects with advanced simulation? Explore the partnership here.