Ever wondered how solenoids work? These small but powerful electromagnetic devices convert electrical energy into motion; using a magnetic field to move a plunger that controls valves, switches, and actuators in everything from cars to industrial equipment.

Sounds interesting?

Let’s take a closer look at how it all works.

Solenoid Simulation in Action

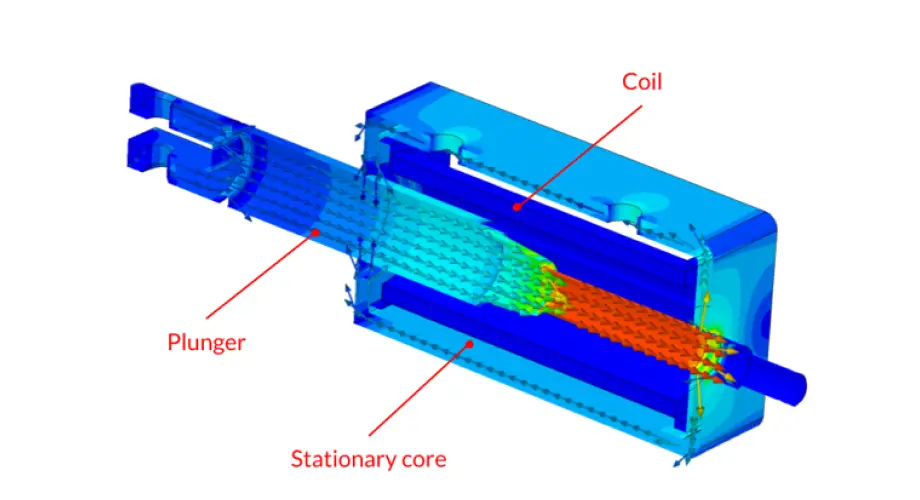

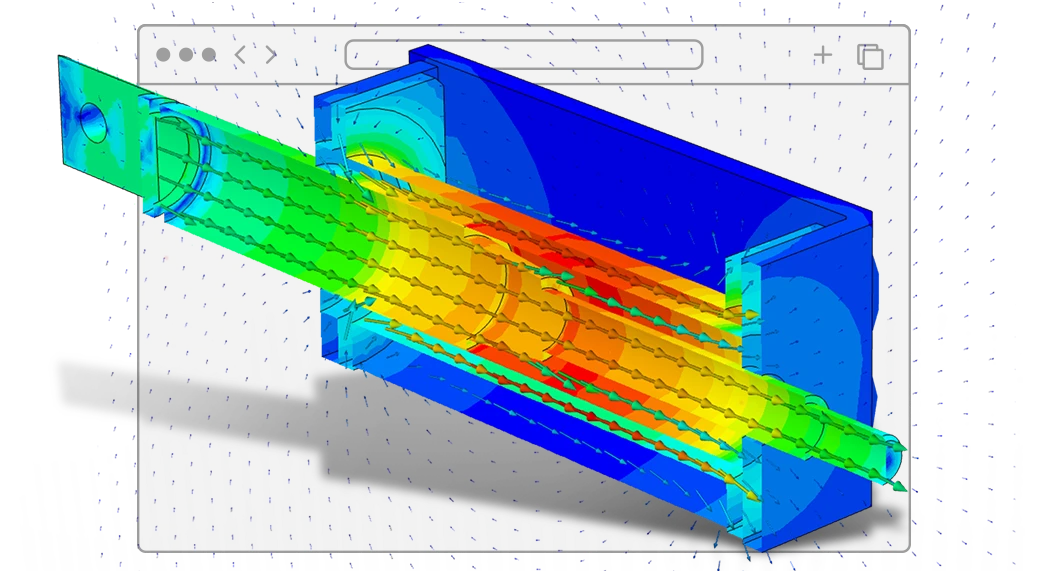

Solenoid actuators drive everything from locks to safety mechanisms, but designing them requires balancing multiple competing physical effects. In this video, we unpack the complete design validation process for a solenoid valve using SimScale’s cloud-native platform, which allows you to run high-fidelity multiphysics simulations without expensive hardware.

What is a solenoid?

A solenoid, a coil of wire, is an electromechanical device that uses electromagnetism to produce controlled motion. As an electric current passes through the wire coil, magnetic field that can move a ferrous armature is generated.

What is the function of a solenoid?

This controlled motion of a solenoid can open or close valves to control fluid flow in hydraulic and pneumatic systems, engage locks, activate switches – depending on the application.

Solenoids are widely used as they can provide precise motion control using electricity alone, without a need for complex mechanical linkages.

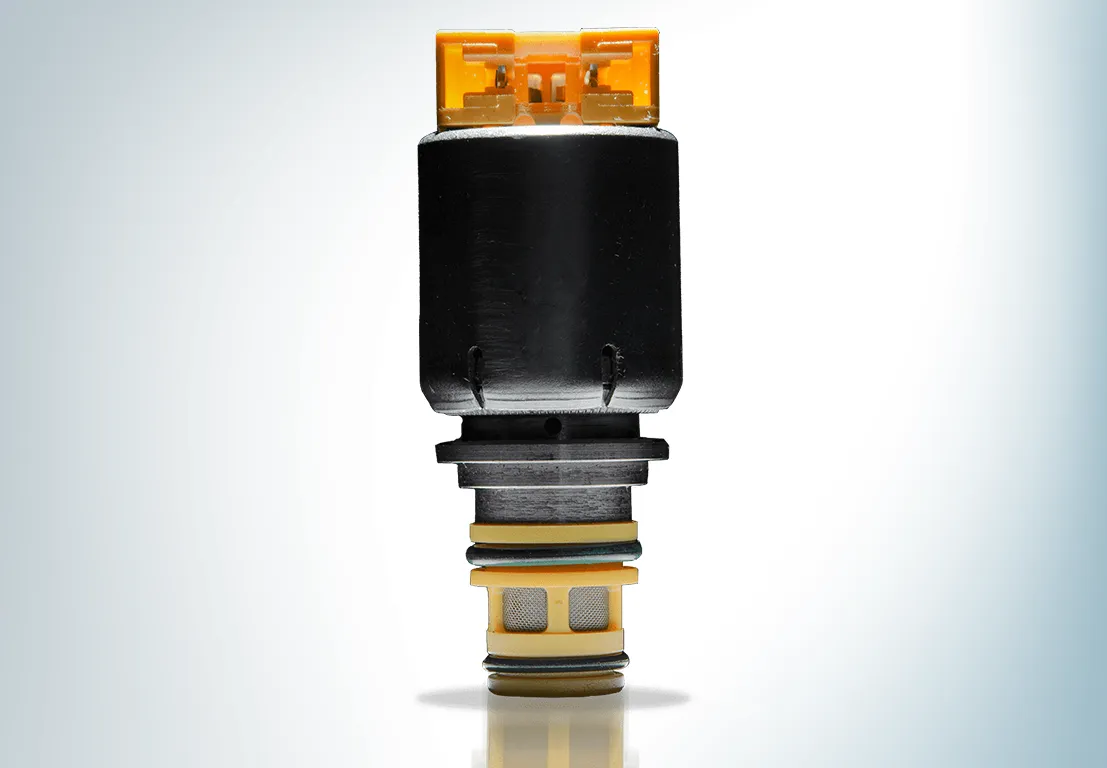

Parts of a Solenoid

Here is a breakdown of the key components that work together to generate and utilize a magnetic field for mechanical action.

| Part | Description | Key Design Considerations |

|---|---|---|

| Coil (Winding) | A copper wire tightly wound around the stationary core, where the electrical current is passing through. | Number of turns, wire gauge, current capacity, and insulation material determine field strength and heat dissipation. Coil design must balance force, efficiency, and temperature rise. |

| Stationary core | A ferromagnetic cylinder that provides a low-reluctance path for the magnetic flux generated by the coil. It concentrates the field and enhances magnetic force on the plunger. | Material selection, geometry, and surface finish affect magnetic permeability and saturation. Must minimize eddy current and hysteresis losses. |

| Plunger (Armature) | Part of the stationary core that moves under the influence of the magnetic field. | Stroke length, mass, and surface finish affect response speed and reliability. |

| Spring | Returns the plunger to its original position when the coil is de-energized. | Spring constant (stiffness), preload, fatigue life, and temperature resistance. Must be designed to balance return force with electromagnetic pull for proper actuation timing. |

How does a solenoid work step-by-step?

To truly understand how a solenoid works, it helps to look inside and observe what takes place the moment electricity is applied.

Below is a step-by-step explanation of the entire process – starting with the initial flow of current and ending with the resulting mechanical motion:

- Electrical current energizes the coil (solenoid activation) : Once voltage is applied to the solenoid, electrical current starts flowing through the copper winding. This flow of electricity creates a magnetic field around the coil, a process explained by Ampère’s Law. How strong this magnetic field gets depends on factors such as: the number of turns in the winding, how strong the current is, and the magnetic permeability of the core material.

- Magnetic field strengthens and focuses in the core: Next, the stationary core – usually made of something like soft iron – channels and intensifies the magnetic flux created by the coil. This process creates a powerful magnetic circuit between the core and the plunger (also known as the armature). At this point, the magnetic energy is concentrated and ready to push the plunger into motion.

- The plunger is pulled in: Now the magnetic force comes into play, pulling the plunger toward the coil’s center. This is how electromagnetic energy is converted into linear mechanical motion. Depending on how the solenoid is built, the plunger either moves in (pull-type) or pushes out (push-type). That movement is what performs the work – whether it’s flipping a switch, opening a valve, or locking something into place.

- Power off – the spring takes over: As soon as the power is cut, current stops flowing and the magnetic field fades away. Without that force holding the plunger in place, the return spring takes over and pushes the plunger back to its ‘resting’ position. This mechanism ensures fail-safe operation and resets the solenoid for its next activation.

Types of Solenoids

Without realizing it, solenoids are actually used every day for a variety of purposes – quietly powering a wide range of devices.

Their adaptability in size and strength makes them suitable for everything from small gadgets to heavy-duty machines. Different jobs call for different traits – like how fast they respond, how much energy they use or how they move – so there are many types of solenoids, each built to handle specific tasks.

Solenoid types can be broken down as follows.

Based on function and design

- Linear solenoids: These produce a linear, in-and-out motion, most commonly seen in push/pull applications.

- Push/pull (or monostable): The armature moves in or out when the coil is energized and returns to its original position when the power is removed, often with the help of a spring.

- Latching (or bistable): These require a pulse of energy to move to an “on” or “off” state, and they stay in that position without continuous power.

- Proportional: The position of the plunger is proportional to the amount of power supplied to the coil.

- Rotary solenoids: These create a rotational motion instead of linear movement.

- Solenoid valves: These control the flow of fluids or gases by using a solenoid to open or close a valve.

- Direct-acting: The solenoid directly opens or closes the valve, and this can be done with or without pressure acting on the valve.

- Pilot-operated (or indirect-acting): These use the fluid pressure as a pilot force to help operate the valve.

Based on electrical type and frame design

- AC solenoids: Solenoids designed to run on alternating current, often using a laminated frame to prevent buzzing.

- DC solenoids: Solenoids designed to run on direct current.

- C-Frame solenoids: These have a C-shaped frame around the coil and are popular in many DC applications.

- D-Frame solenoids: These have a two-piece, D-shaped frame and are commonly used in industrial applications.

Solenoid Applications

Compact, efficient, and remarkably versatile – solenoids play a quiet but crucial role in powering modern technology.

Whether in automotive, manufacturing equipment or medical devices, their ability to deliver precise motion makes them indispensable to today’s engineering solutions. Let’s explore some of the most common and important solenoid applications.

| Application Field | Specific Use Case | Why a Solenoid is Used / Benefit |

|---|---|---|

| Powertrain and Engine Control | Fuel-injector control, starter solenoid, shift solenoids, transmission valve body solenoids (gear shifting) | Improved fuel efficiency by ensuring timely gear changes, smoother transitions, fluid temperature management |

| Body and Comfort Systems | A/C system control, door lock/unlock mechanisms, trunk/hood latches | Compact solenoid actuators provide reliable motion for locking/unlocking, remote control, and safety interlock functions |

| Process Control and Valves | Solenoid-controlled hydraulic valves, pneumatic cylinders in manufacturing systems, robotic actuator control, on-off and proportional valves in process plants | Solenoids allow quick fluid or air flow control, increasing automation, precision, safety and response times on the production line |

| Industrial Automation | Conveyor diverters, gate actuators, locking pins in robotics or automated assembly lines | Deliver rapid, programmable mechanical movement, bridging electronic control systems with physical motion for smart manufacturing and robotics |

Design & Simulation of Solenoids

Designing a well-functioning solenoid involves carefully balancing several interdependent factors – including magnetic strength, actuation speed, heat buildup, and in certain cases, fluid behavior. The key design challenge is to ensure the solenoid generates sufficient electromagnetic force to move the plunger reliably, all while avoiding overheating or performance drops under real-world conditions.

Since solenoids operate through interconnected physical processes, their design requires consideration of multiple physics. The flow of electric current produces a magnetic field, which in turn drives motion and can cause heat generation. In valve-related applications, this motion further influences fluid pressure and flow.

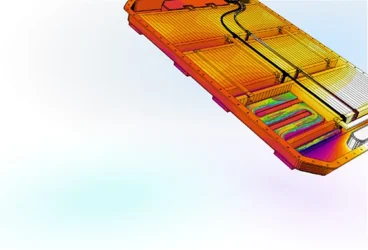

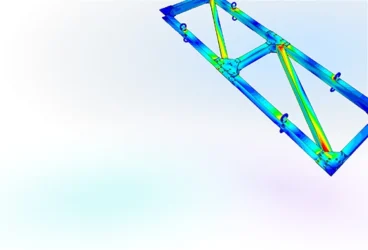

Accurately modeling these various physical phenomena requires a combination of electromagnetic, thermal and fluid dynamics simulations.

With SimScale’s cloud-based multiple physics platform, engineers can simulate and refine every aspect of solenoid behavior in a single workspace – from observing magnetic field distribution to assessing thermal performance and analyzing internal fluid flow. This holistic simulation approach speeds up development, cuts down on physical prototyping and ensures consistent performance across a wide range of use cases.

Solenoids in our projects

Here are some amazing SimScale projects simulating solenoids.

FAQs

Commons causes of solenoid failure are; electrical problems such as incorrect voltage, power surge or poor connection, mechanical problems such as wear and tear, excessive pressure or improper installation, and environmental problems such as extreme temperatures, moisture or vibration can degrade the components

To choose the right solenoid, you first need to define your application’s performance parameters/criteria. The best way to accomplish this is to use the following factors as a guideline: Solenoid size/geometry, Direction of the required motion, Solenoid stroke length, Actuation force, Duty cycle, Environmental factors

SimScale allows engineers to carry out multiple physics simulations in a single platform that reflects the complete behavior of a solenoid valve – including its electromagnetic characteristics as well as thermal and fluid analysis. Based on specific design objectives, multiple simulation types can be integrated to deliver a comprehensive, end-to-end analysis.