From tightening regulatory standards on water purity and air quality, to the drive for lower energy consumption and operational efficiency across industrial equipment and manufacturing, industries today face mounting challenges in filtration system design. Equipment manufacturers and plant designers need filtration solutions that perform reliably and efficiently under the full range of environmental and operating conditions. Crucially, they need to be able to deliver these systems faster than the competition. That is where filtration simulation comes in.

Filtering Out the Engineering Challenge

The performance of filtration media is influenced by several factors. One is the design of the design of the inlets, outlets and housing that immediately surround the filter. But just as important is the uniformity of the onset flow that arrives at the filter from the upstream equipment. In short, to ensure that filters are performing to their specifications, you need to test them in-situ, under real operating conditions.

At the same time, filtration systems themselves are becoming more complex, involving multiphase fluids, fine particles, and sophisticated media. Traditional design workflows that rely on physical prototypes and iterative testing are no longer sustainable for organizations striving to compete at the highest level.

CFD Simulation: The Filtration Engineer’s Essential Tool

Computational Fluid Dynamics (CFD) simulation provides a window into the complex flow behaviors that drive filtration performance. CFD allows teams to optimize pressure drop, maximize particle capture, and mitigate the risk of fouling or early failure, with no need for expensive physical protoypes.

Engineers are free to investigate the influence of filter geometry, placement, and operational parameters, while simulation also provides crucial quantitative data that is essential for certifying system performance and validating compliance with evolving regulations.

This digital transformation of the design process translates to shorter development cycles, greater innovation, and increased confidence.

The SimScale Advantage: Cloud-Native, Fast, and Accessible Filtration Simulation

While CFD is a powerful tool, in many organizations this power is locked away in siloed simulation teams, limiting accessibility and value realization. Broader usage is hampered by legacy simulation tools which are costly, complex, and constrained by local computing resources. SimScale’s cloud-native platform breaks down these barriers, making CFD accessible to every designer and engineer, regardless of their organization’s size or IT infrastructure.

Filtration simulation using SimScale’s browser-based environment eliminates the need for specialized hardware. Engineers can run even the most demanding filtration simulations from anywhere. With the power of the cloud, simulation jobs scale dynamically, with no queues or limited workstation capacity.

SimScale accelerates the design cycle further with AI-driven features and automation. AI acceleration translates to faster compute times and easier access to explore designs, empowering teams to test more scenarios and optimize sooner.

SimScale’s recent webinar dives deeper. The session demonstrates how SimScale enables rapid, high-fidelity assessments of filtration systems. Take a look at the recording to see how cloud-native simulation unlocks critical insights for filtration system designers, and how to leverage these insights to rapidly test design changes to improve system performance.

Real-World Impact of Filtration Simulation: See the Results

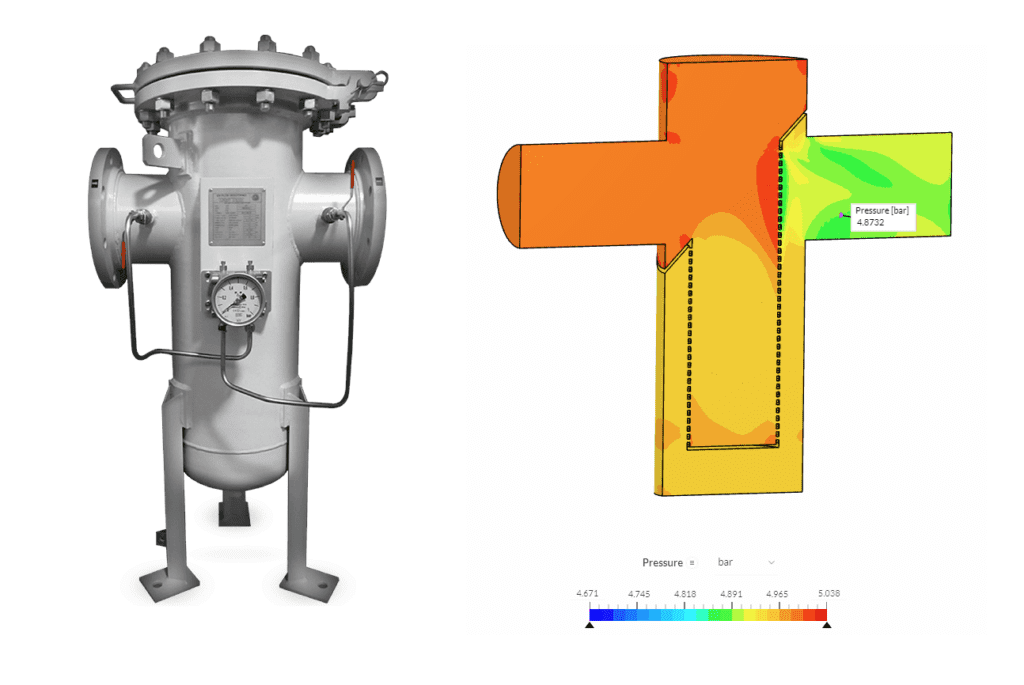

Case Study: GV Filtri

GV Filtri is a manufacturer at the forefront of industrial filtration innovation. They use CFD and FEA simulation with SimScale to support research and development activities as well as to validate performance against individual customer requirements. Having rapid access to simulation tools allows them to value engineer their products for cost containment and increased market competitiveness.

With SimScale, GV Filtri moved beyond the limitations of analytical calculations to be able to accurately predict pressure drop performance of their products, allowing them to take better informed design decisions and communicate these results easily to external stakeholders.

The case study highlights how SimScale’s fast, browser-based platform enabled the GV Filtri team to run detailed simulations without investment in specialized hardware. They performed parametric studies to pinpoint the optimal configuration for their application, iterating much more rapidly than before.

The result was a better-performing, more efficient product brought to market in record time. Read the full GV Filtri case study here.

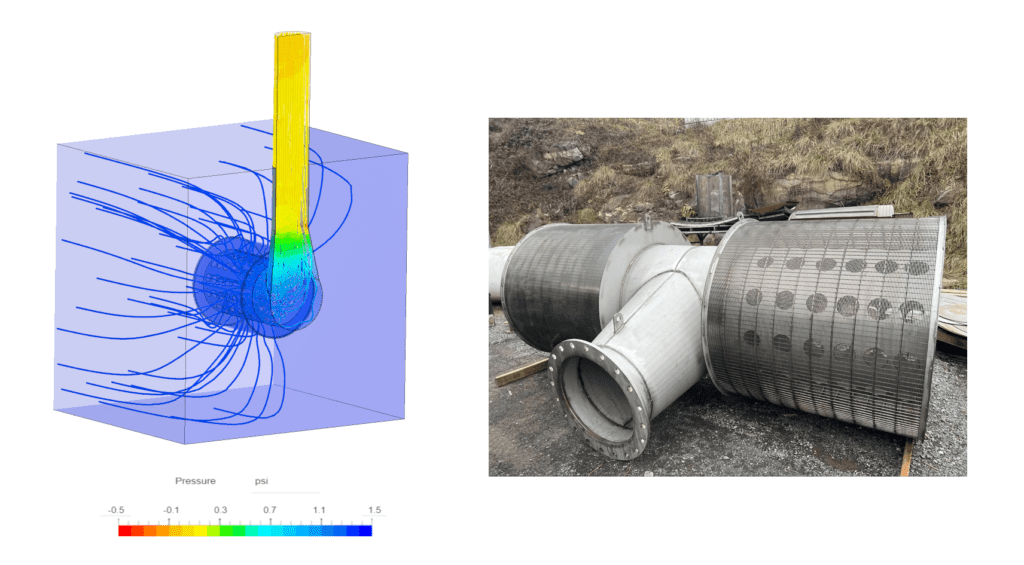

Case Study: Elgin Separation Solutions

Elgin Separation Solutions, a global provider of specialized industrial processing equipment. Their water intake division provides solutions designed to deliver water to industrial systems in a way that is both efficient and environmentally safe. Proper design of industrial water intakes is essential for ensuring uniform flow distribution, limiting hydraulic losses, and achieving compliance with operational requirements.

With SimScale’s intuitive cloud-based CFD, Elgin’s engineers are able to rapidly explore different design variants when configuring water intakes for each unique project. The platform allows them to visualize flow patterns, identify zones of high flow velocity, and fine-tune structures to optimize hydraulic performance. Crucially, Elgin leverages SimScale’s scalability to run simulations in the cloud to reduce overall project timelines, and deliver better performing products. Explore Elgin’s case study here.

Shaping the Future of Filtration System Design

The pressure on industrial filtration system designers is not going away. Success now depends on the ability to respond with agility, precision, and confidence. Cloud-native, AI-accelerated CFD from SimScale empowers engineers to meet these challenges head-on, delivering superior products, faster—at a lower cost and risk profile.

If you’re responsible for innovation, compliance, or operational excellence in filtration systems, now is the time to make cloud-native simulation a core part of your workflow.