Finite Element Analysis simulation concept developed from the theoretical basis established by the finite element method (FEM), which was founded with the publication of a set of scientific papers in the 1940s.

Created as numerical techniques for finding approximate solutions to boundary value problems for partial differential equations, FEM software is based on a problem domain’s subdivision into simpler parts—called finite elements—, and on the calculus of variational methods to minimize an associated error function.

The scientific pillars of the finite element method are a direct result of the need to solve complex elasticity and structural analysis problems in civil and aeronautical engineering. The first development can be traced back to the work of A. Hrennikoff in 1941[1] and R. Courant in 1943[2]. Although these pioneers used different perspectives in their finite element approaches, they each identified the one common and essential characteristic: mesh discretization of a continuous domain into a set of discrete sub-domains, usually called elements. Another fundamental mathematical contribution to the FEM is represented by the book “An Analysis of the Finite Element Method” by Gilbert Strang and George Fix, first published in 1973 [3]. Since then, FEM has been generalized for the numerical modeling of physical systems in many engineering disciplines including electromagnetism, heat transfer, and fluid dynamics.

Finite Element Method Benefits of the Finite Element Method (FEM)

Many specializations under the umbrella of mechanical engineering, such as the aeronautical, biomechanical, and automotive industries, are commonly using integrated FEM in product design and development. Several modern FEM packages include specific components such as thermal, electromagnetic, fluid, and structural working environments. For example, in a structural simulation, the FEM helps in “producing stiffness and strength visualizations and also in minimizing weight, materials, and costs”.[4]

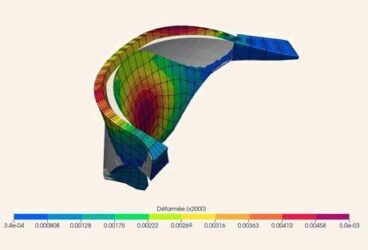

The main capability of FEM is its detailed visualization of bending and twisting places for a structure, indicating stresses and displacement distribution. Modern FEM applications software offer a variety of simulation options for modeling and analysis.

Some of the core benefits of FEM include “increased accuracy, enhanced design and better insight into critical design parameters, virtual prototyping, fewer hardware prototypes, a faster and less expensive design cycle, increased productivity, and increased revenue”.[5]

Over the course of modern engineering history, FEM algorithms were embedded in many powerful design tools, contributing to raising the standards of engineering and significantly improving the design process.

Using FEM algorithms integrated into FEA applications, any engineering structure design can be developed, tested, and modified in advance, long before the manufacturing of product prototypes.

Additionally, using the same digital format, any product can be optimized at any phase of the workflow process, from the engineering stage to design and testing in the laboratory. It has also been proposed that FEA software could be used in stochastic modeling for numerically solving probability models.

The purpose of a helmet is to protect the person who wears it from a head injury during impact. In this project, the impact of a human skull with and without a helmet was simulated with a nonlinear dynamic analysis. Download this case study for free.

FEM Main History Milestones

1941-1942 – Hrennikoff and Courant developed mesh discretization methods for solving elasticity and structural analysis problems in civil and aeronautical engineering.

1956 – Ray W. Clough published the first paper on the finite element method (FEM). The term “finite elements” was coined in a 1960 article. [6]

1959 – General Motors and IBM build the computer system DAC-1 (Design Augmented by Computers) to facilitate the design of cars.

1960 – William Fetter from Boeing coins the term “computer graphic” for his human factors cockpit drawings. [7]

1965 – NASTRAN (NASA Structural Analysis) is developed as structural analysis solver tool.

1977 – FIESTA, the first professional FEM p-version code, was initiated by Alberto Peano from ISME.

1982 – PROBE, developed by Barna Szabo and Kent Myers, was the first ‘industrial’ implementation of p-version FEA for research and aerospace applications.

1987 – MECHANICA was developed by RASNA Corp.

2001 – P-version FEM was proven to be the most efficient for plasticity by A. Duster. [8]

2006 – ASME Guide for Verification and Validation in Computational Solid Mechanics is released.

2008 – NASA released a standard for development of models and simulations.

2012 – Barna Szabo and Ricardo Actis introduce “Simulation governance: New technical requirements for software tools in computational solid mechanics”.[9]

2013 – SimScale officially released the world’s first cloud-based 3D simulation platform, offering a comprehensive set of linear and nonlinear FEA capabilities for structural mechanics, fluid dynamics, and thermodynamics. To discover all the features provided by the SimScale cloud-based simulation platform, download this document.

References

- Hrennikoff, A. (1941). “Solution of problems of elasticity by the framework method”. Journal of applied mechanics 8.4: 169–175.

- Courant, R. (1943). “Variational methods for the solution of problems of equilibrium and vibrations”. Bulletin of the American Mathematical Society 49: 1–23.

- Strang, G. Fix, G. (1973). “An Analysis of the Finite Element Method”. Prentice Hall.

- Kiritsis, D. Eemmanouilidis, Ch. Koronios, A. Mathew, J. (2009). “Engineering Asset Management” Proceedings of the 4th World Congress on Engineering Asset Management (WCEAM), 591-592.

- Hastings, J.K. Judes, M.A. Brauer, J.R. (1985) “Accuracy and Economy of Finite Element Magnetic Analysis”. 33rd Annual National Relay Conference

- Clough, R.W. (1960) “The Finite Element Method, in Plane Stress Analysis”, Proc. 2nd A.S.C.E. Conf: on Electronic Comp., Pittsburgh, PA

- Carlson, W. (2003) “A Critical History of Computer Graphics and Animation”. The Ohio State University

- Duster, A. (2001) “The p-version of the Finite Element Method compared to an adaptive h-version for the deformation theory of plasticity”. Computer Methods in Applied Mechanics and Engineering Journal Impact Factor & Information.

- Szabó, B. Actis, R. (2011) “Simulation governance: New technical requirements for software tools in computational solid mechanics”. International Workshop on Verification and Validation in Computational Science University of Notre Dame, October 2011