Unlock holistic analysis – from transient fluid dynamics and rotational modal analysis to core loss modeling – all within an intuitive, high-performance cloud environment.

Accelerate your rotating machinery simulation workflow. Leverage cloud-native multiphysics to simulate transient fluid dynamics, rotational modal analysis, and electromagnetic performance simultaneously.

Test pumps, fans, turbines, and motors under real-world conditions. Iterate on geometry and operating points in seconds—not days—to ensure your rotating engineering design delivers peak efficiency and durability.

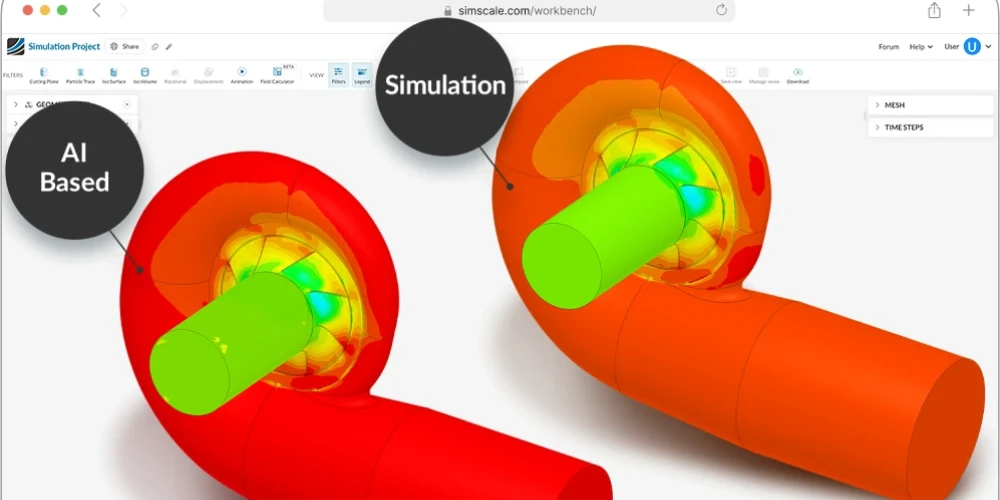

Use AI surrogates and pre-trained foundation models to get performance predictions in seconds. Explore thousands of design variants—from impeller shapes to stator configurations—and identify winning concepts before committing to high-fidelity analysis.

SimScale AI unlocks new ways to innovate in industrial equipment simulation. Explore whole design spaces in minutes and make design decisions with confidence, reducing iterations and increasing engineering velocity.

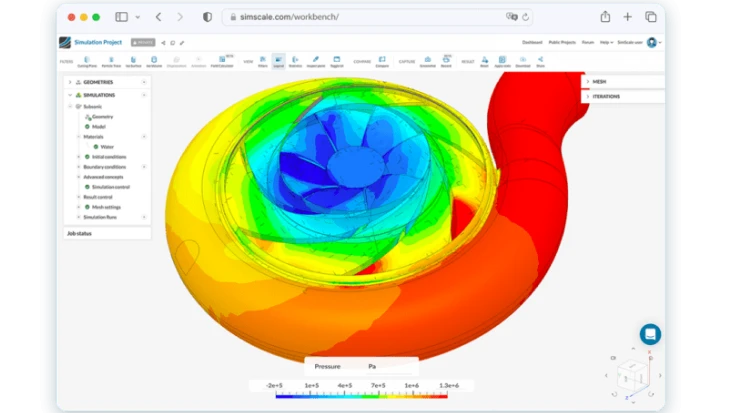

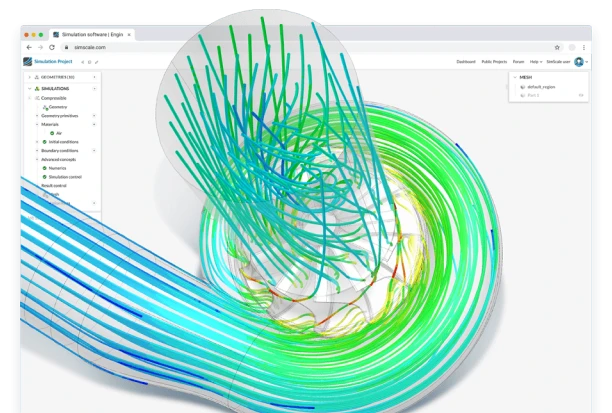

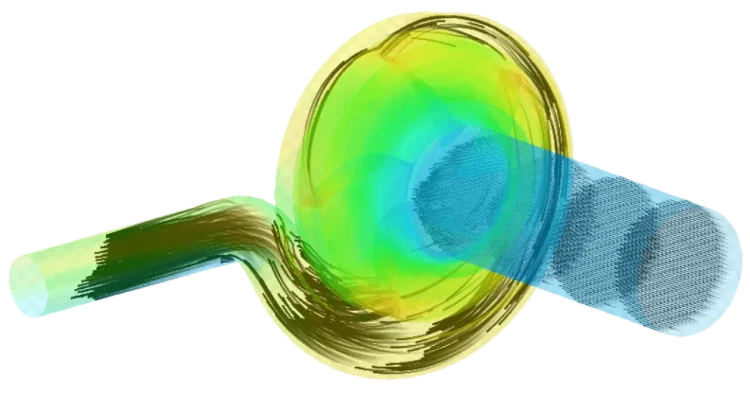

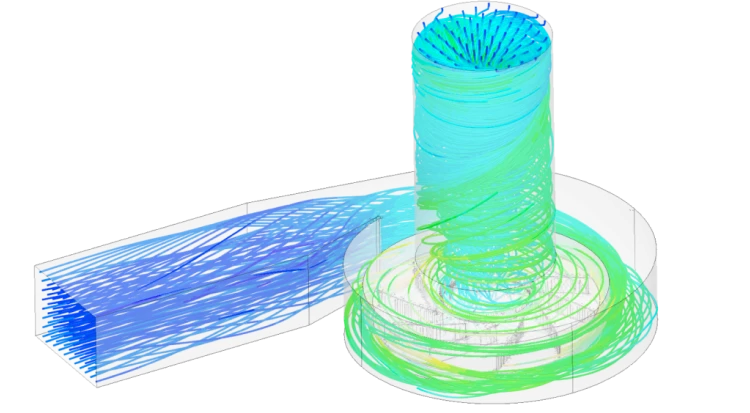

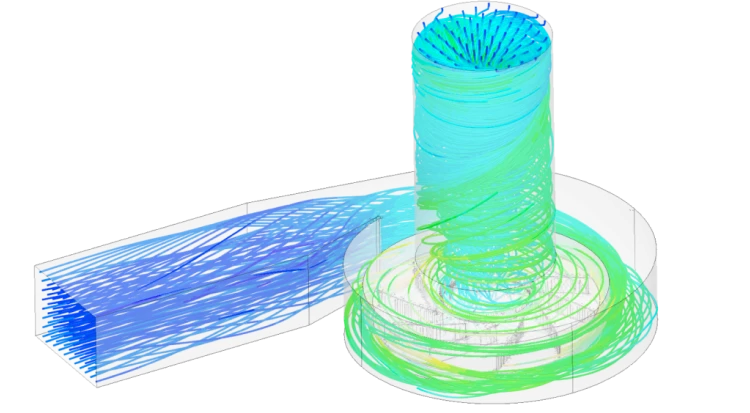

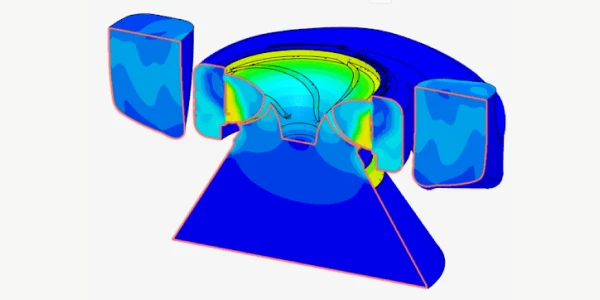

Capture Every Flow Detail Master the complex fluid dynamics defining your product’s performance. Whether you need rapid performance mapping via Multiple Reference Frame (MRF) or need to capture intricate wake interactions with full transient Sliding Mesh (AMI), SimScale adapts to your pace.

Don’t simplify your reality—simulate it. From the chaotic multiphase flows inside industrial mixers to critical cavitation risks in pumps, get the high-fidelity insights you need to push rotating machinery analysis to the limit.

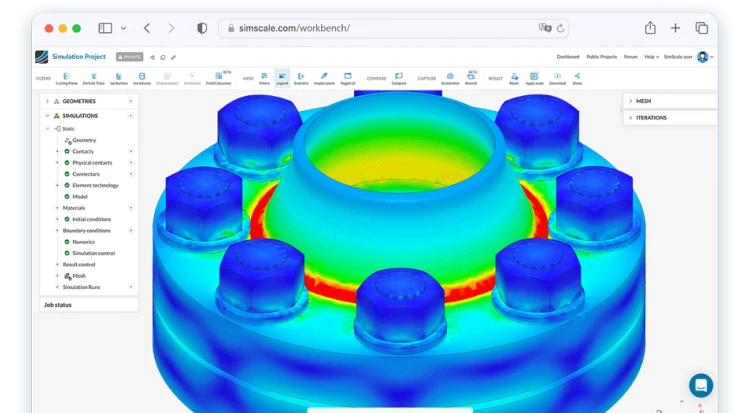

Push your design to the edge, then ensure it stays there. Assess vibration, thermal stress, and fatigue on high-speed rotors with confidence. Use Rotational Modal Analysis to generate Campbell Diagrams and spot critical resonance speeds long before hardware testing.

Go beyond the rotor. Validate the integrity of static rotating equipment—casings, volutes, and baseplates—against dynamic loads like unbalance and shock. With SimScale, you ensure that every inch of your rotary equipment installation is built to last.

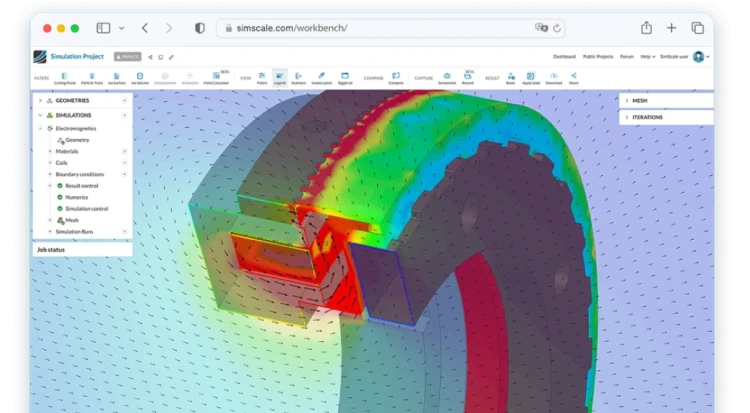

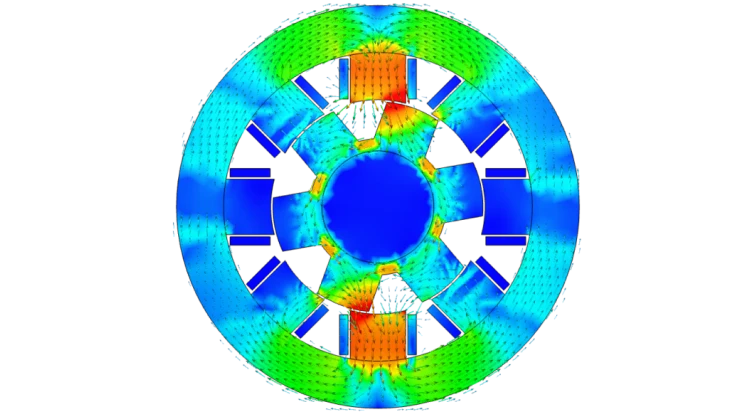

The motor is the heartbeat of your machine—optimize it without compromise. Our specialized solvers for rotating engineering design let you visualize static magnetic fields and capture complex eddy current phenomena with speed and accuracy.

Hunt down inefficiencies. Calculate hysteresis and core losses to maximize output, and define permanent magnet magnetization to smooth out torque ripple. It’s the fastest path to a high-efficiency electric drivetrain.

Real-world machinery doesn’t respect physics boundaries, and neither should your simulation. Break down the silos by coupling solvers to reveal the complete picture. Map electromagnetic losses or fluid temperatures directly onto structural models to uncover hidden thermal stresses.

Bridge the gap between aerodynamics and durability. Transfer pressure loads from CFD to FEA to guarantee blade strength, and run parametric sweeps across all domains to find the perfect balance for your rotating machinery design.

Stop guessing and start mapping. Generate comprehensive pump performance curves in parallel, sweeping across flow rates simultaneously. Visualize head-flow characteristics and identify the Best Efficiency Point (BEP) in minutes, not days.

Unlock maximum energy extraction by analyzing transient flow patterns around water turbines. Assess performance under fluctuating conditions and refine blade geometry to ensure hydraulic stability and peak power generation.

Take the guesswork out of industrial equipment simulation. Analyze mixing efficiency and multiphase behavior to ensure absolute process consistency. Eliminate dead zones and thermal non-uniformities to guarantee safety and product quality.

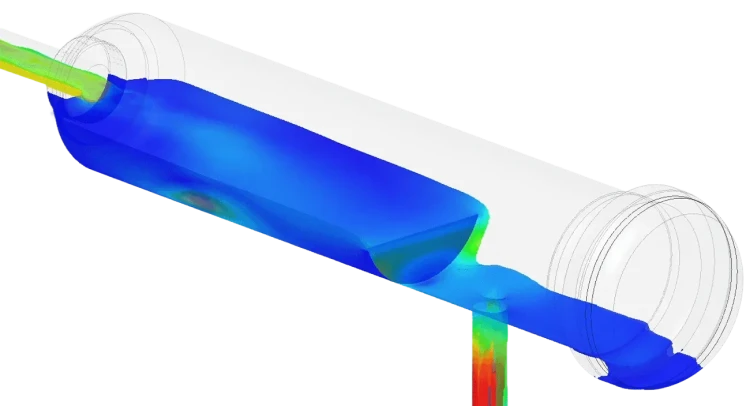

Accelerate your development cycle for turbochargers and fuel cells. Leverage the cloud to generate accurate compressor maps for varying speed lines rapidly, defining surge lines and choke points without the hardware bottleneck.

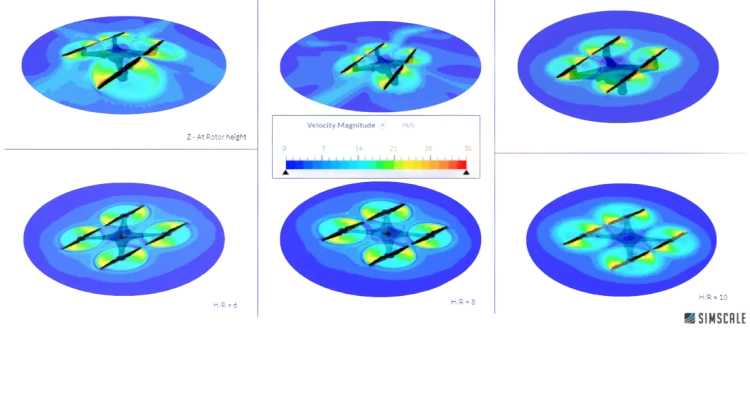

Balance acoustics with performance. Test and validate industrial fans and blowers for P-Q efficiency instantly. From simplified fan modeling to full 3D geometric optimization, find the aerodynamic sweet spot that reduces power consumption and noise.

Whether it’s a UAV micro-rotor or a massive marine propeller, master propulsion efficiency. Visualize cavitation volume fractions to predict erosion and noise, ensuring your design delivers maximum thrust and torque under any condition.

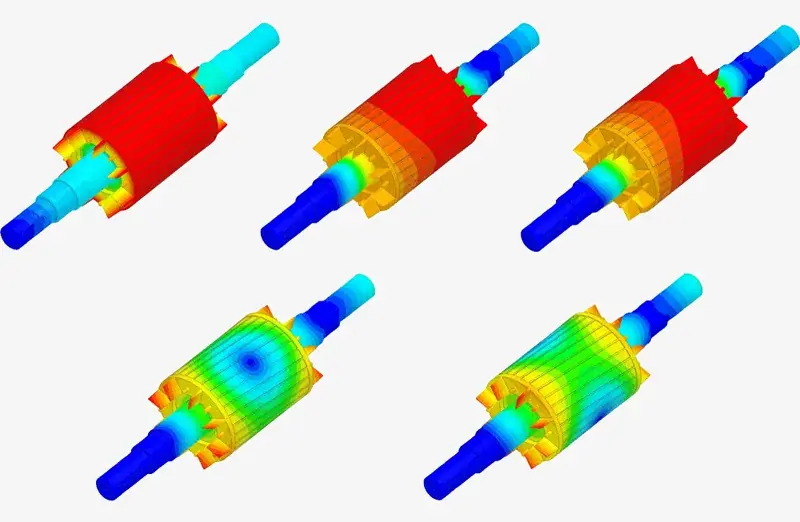

Design electric motors without limits. gain deep insights into torque generation using the EM solver, then seamlessly couple with thermal analysis to engineer cooling systems that prevent overheating and extend the life of your machine.

By switching to SimScale, Hazleton Pumps reduced simulation time from weeks to just 7 minutes—a 99.9% acceleration. This cloud-native efficiency saved them over $200,000 on a single retrofit project, all while maintaining result accuracy within 3% of physical tests.

Check out the latest thermal management simulations performed in SimScale and validated against experimental and/or analytical results.

Check out our amazing content written by our in-house experts.

Check out the latest thermal management simulations performed in SimScale and validated against experimental and/or analytical results.

Subscription Plans Adapted to Your Needs

Free for testing & learning

For higher fidelity simulation work

For team collaboration

For broad simulation roll-outs

Absolutely. SimScale offers high-fidelity capabilities for rotating machinery analysis, including full cavitation modeling (NPSHr studies), multiphase flow for mixers and marine propellers, and transient Sliding Mesh (AMI) interfaces to capture complex rotor-stator interactions and wake effects.

You only need a standard laptop and an internet connection. SimScale offloads the heavy lifting to the cloud, giving you access to HPC (High-Performance Computing) resources on demand. You can run hundreds of complex parallel simulations—like pump curves or compressor maps—simultaneously without slowing down your local machine.

Yes. SimScale’s solvers are rigorous, industry-proven, and validated against both analytical and experimental data. We provide a comprehensive library of validation cases for pumps, fans, turbines, and motors to demonstrate that our results match real-world physics within critical engineering tolerances.

SimScale supports all standard CAD formats (including STEP, IGES, Parasolid, and STL) and offers direct plugins for major CAD tools like SolidWorks, Autodesk Inventor, and Revit. You can import your geometry directly, and our platform automatically detects fluid domains and rotating zones to streamline setup.

Not at all. Since SimScale is 100% cloud-native, there’s nothing to download or install. You access the full power of our platform directly through your web browser. This means no waiting for large installers, no managing license servers, and no hardware compatibility headaches – just log in and start simulating.

Sign up for SimScale

and start simulating now