Cloud-based simulation to test, validate, and iterate designs easily

For temperature-sensitive biopharmaceuticals, freezing and thawing rooms along with processes, equipment, and freeze-thaw chambers need to function at their best to avoid premature degradation, minimize the risk of microbial growth, and prolong shelf life. Controlled freezing and thawing rates are absolutely crucial to maintaining stability and quality of biotech and biopharma products, particularly where proteins are involved. Uncontrolled freezing and thawing can quickly alter a product’s properties and even lead to product loss.

Freezing and thawing units are used in a range of medical/pharma applications including:

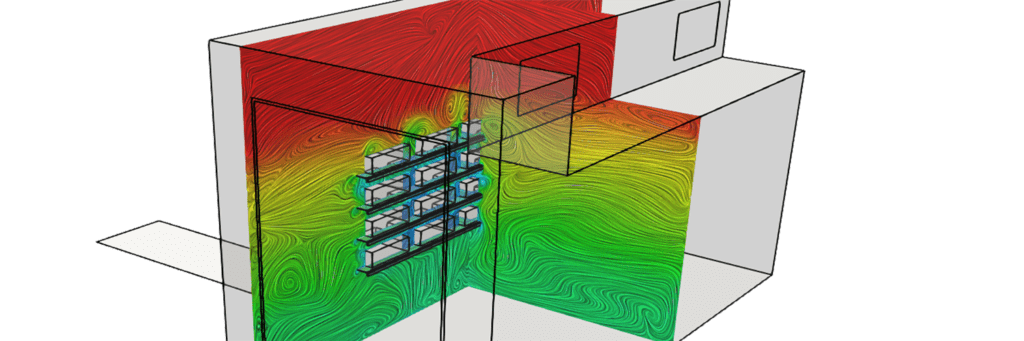

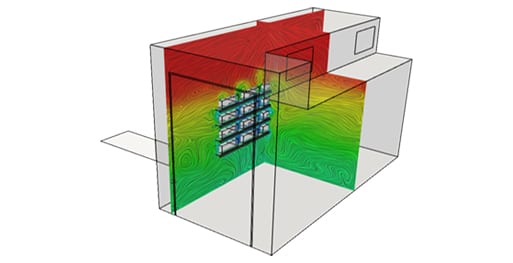

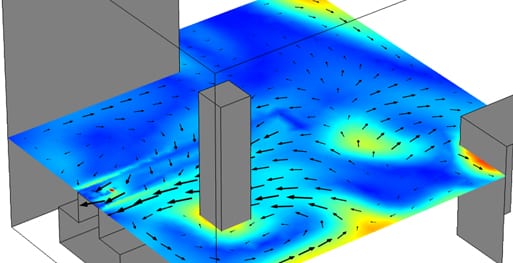

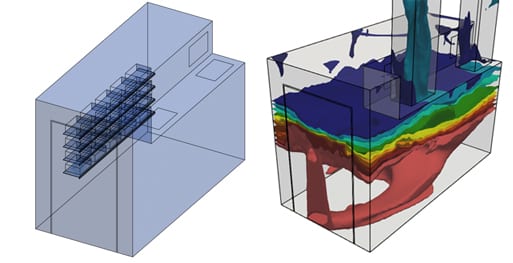

Where airflow and heat are concerned, simulation can be extremely useful in assessing and improving HVAC design. Using online simulation you quickly and easily visualize air behavior and identify areas of recirculation or unstable temperatures. Whether assessing an existing thawing unit or optimizing a design before construction, simulation offers engineers the results they need to ensure a stable and controlled environment for freezing and thawing processes.

However, the steep cost of hardware and steep learning curves of traditional, on-premises tools leave many designers to feel that simulation is not an option. SimScale has eliminated such traditional hurdles, thanks to the power of the cloud. With SimScale, engineers can:

In addition to adequate freezing and thawing equipment, an important contributor to freeze-thaw stability is proper HVAC design. Biopharma products can be extremely sensitive to temperature, air, and light exposure. Maintaining consistent freeze-thaw rates for all products within a cabinet relies on valid assessment of photostability, airflow, heat transfer, and average ambient temperatures. See how CFD can be used to assess airflow in healthcare environments in this webinar.

When a client wanted to analyze the airflow within a thawing room where 20 frozen packs are thawed at -40 degrees C, SimScale created a simulation to enhance understanding of air changes and the local mean age of air within the design. See the initial results of the convective simulation performed and how the results led to improvements in the design in this presentation. View the slides here:

Sign up for SimScale

and start simulating now