Withings created the first smart scale in 2009 and has been the pioneer in connected health ever since. Its clinically validated and multi-award-winning range is used by millions worldwide and includes smart scales, hybrid watches, blood pressure monitors, sleep analyzers, and more. The team of engineers, data scientists, and healthcare professionals at Withings work alongside clinical experts to make it possible to take medical-grade measurements at home. Withings was the first to bring measurements for pulse wave velocity and electrodermal activity into the home – finding ever more precise ways to measure our health. Withings Health Solutions, its dedicated division serving healthcare professionals across chronic disease prevention and management, remote patient monitoring, clinical research, and more, helps bridge the gap between patients and their care teams.

Health monitoring devices must be highly accurate and provide valuable data. Critical lifesaving and care decisions rely on healthcare professionals receiving data from devices they can trust. The devices must be robust, fit for purpose, and operate effectively in various environments. Withings has been leveraging engineering simulation in the cloud via the SimScale platform to gain more engineering insight into their product development processes. Engineers at Withings benefit from having access to powerful physics analysis capabilities in the cloud with virtually unlimited computational power and storage, all accessed via a web browser from anywhere.

The engineering team at Withings has been using SimScale for structural analysis for developing monitoring equipment. Victor Pimenta, a mechanical engineer with Withings based in Paris, France, has been using SimScale to perform FEA on a snap-fit mechanism for one of their blood pressure monitoring devices, BPM Connect. BPM Connect was developed with the help of leading cardiologists and has been thoroughly tested against several reference devices to ensure best-in-class blood pressure accuracy. Snap-fit joints are a commonly used component for connecting plastic parts. They are a suitable replacement for fasteners such as screws or rivets, as they weigh less and are easier to assemble. The device’s structural robustness, the mechanism of placement on the patient’s arm, and its ease of use are essential for accurate readings considering it is designed for home use by non-medically trained persons.

The device uses a simple snap-fit clip mechanism for fastening that must exhibit long-term durability against the frequency of everyday use. It must be lightweight with enough strength to mate two fastening parts together. It will thus replace screws and offer significant weight reduction. It is easy to manufacture using injection molding and hence simple to assemble. The correct design and development of such a clip mechanism would require multiple physical prototypes for each design variant. These prototypes are often not a direct representation of the final injection molded part either, thus introducing testing errors that could lead to skewed results. Physical prototyping also gives less quantitative data on focus and stress on the prototype, and section visualization is impossible. There is also no direct feedback loop into refining the design or using the design of experiment or optimization tools, for example. All this means that using virtual prototypes and testing using engineering simulation is the primary method to explore and leverage. Withings has created digital twins of their health devices and can now run numerous design variants simultaneously using the parallel simulation capabilities in SimScale. This ability has significantly added to the engineering abilities and skills at Withings along with the following product design benefits:

By using the novel mechanical simulation based in the cloud offered by SimScale, we engineers at Withings have been able to reduce our design-to-prototype cycles from weeks to days. This tool widens our possibilities to test new designs, materials, and techniques and anticipate possible failures, as well as gains in mechanical performance within a few clicks.

Victor Pimenta

Mechanical Engineer at Withings based in Paris, France

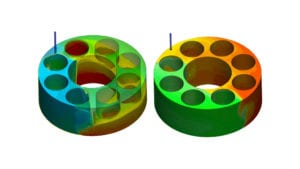

In the case of the snap-fit clip, Withings is interested in some essential design outputs, namely the mating force for the snap-fit mechanism and the deformation experienced by the clip. Using SimScale, engineers at Withings have been able to calculate insertion/extraction forces and visualize section stresses to identify potential fault zones inside the snap-fit component. Such data is also used to predict lifetime.

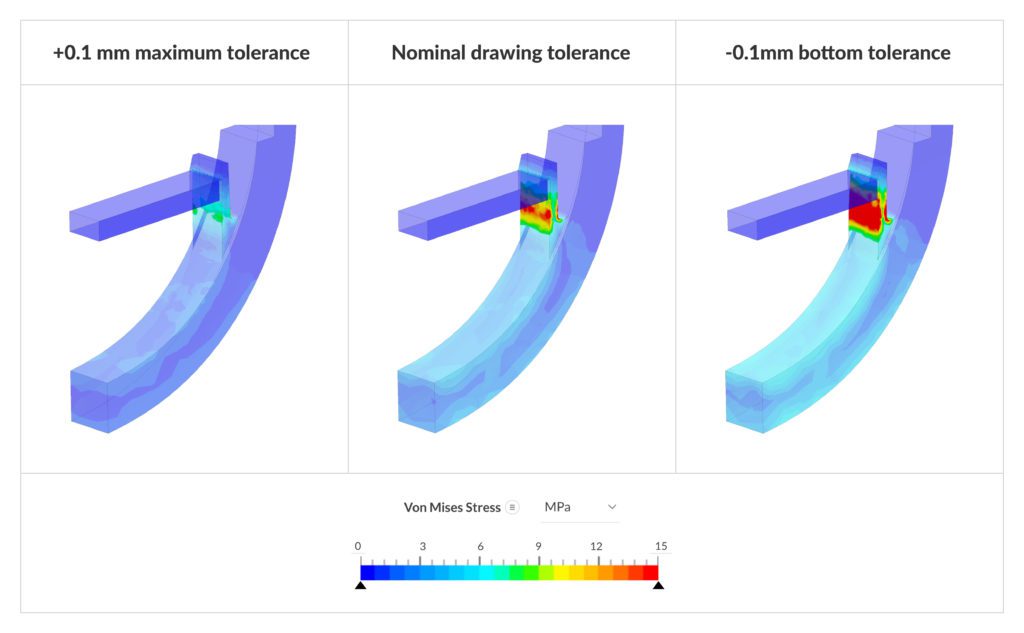

This case also has a nonlinear analysis due to the large deflection of the beam and the nature of the physical contact between the catch and the mating part in the clip. Withings has been able to ascertain the maximum stresses, deformations, and mating forces for different tolerances of the same design. Using a scenario analysis approach, for example, they based a comparative study on having a nominal case with two additional cases (see image below):

Withings has shown how nonlinear static analysis in early-stage design allows engineers to capture nonlinear effects at a critical design stage. With SimScale, Withings can validate the correct function of snap-fit joints, like those used in their at-home and wearable medical devices. Without access to robust nonlinear analysis, the design decision might have been misinformed, leading to faulty components.

Withings plans to further deploy simulation to more engineers across a distributed team of designers working on existing and novel product designs. Having access to a powerful SaaS tool like SimScale that can scale usage with flexible pricing plans is critical to achieving this goal. The SimScale public application programming interface (API) is another feature that Withings can leverage in the future and will enable them to develop a bespoke workflow for design optimization with third-party CAD tools and optimization algorithms.

Sign up for SimScale

and start simulating now