As the industrial sector accelerates towards Industry 4.0, the demand for real-time data is growing exponentially. Facility managers require continuous monitoring of pipelines, valves, and machinery to predict failures and ensure safety. However, this digitization faces a critical physical barrier: power supply. Traditional hardwired sensors are expensive to install and often require disruptive facility shutdowns. Wireless alternatives, while easier to deploy, typically rely on batteries, introducing a perpetual maintenance burden—especially in hazardous (ATEX) zones or remote locations like district heating substations.

TEGnology, a Danish innovator and spin-off from the Chemistry Department at Aarhus University, addresses this challenge directly. Built on a rigorous technical foundation of patented research into advanced thermoelectric materials, their mission is to enable maintenance-free monitoring by converting thermal energy into electrical power. By utilizing the Seebeck effect, their devices harvest energy from the waste heat of the processes they monitor, using a Thermoelectric Generator (TEG). The TEG powers the device, eliminating the need for cables and battery replacements and creating autonomous sensors that operate for over a decade as a permanent part of the infrastructure.

The task of mastering the thermal complexities required for this technology lies with Development Engineer Jiří Hlaváček. With a background in mechanical engineering, Jiří specializes in the thermodynamics of energy harvesting. His role is pivotal: because the electrical output of a TEG is physically coupled to the heat flux passing through it, the thermal and mechanical designs must work in perfect harmony to extract the energy needed without overheating any of the components. To visualize and optimize these invisible heat flows, Jiří relies on simulation.

For TEGnology, the decision to adopt SimScale was driven by the need to balance enterprise-grade capability with the agility of a specialized startup. Having previously worked with traditional, desktop-based simulation platforms, Jiří found the shift to a cloud-native environment refreshing. He notes that the transition was seamless, stating, “It was a surprise for me how simplified the interface is and how much faster and easier you can set up the simulation compared to legacy tools.” This streamlined workflow allows the engineering team to bypass the steep learning curves often associated with CFD tools, enabling them to focus purely on product innovation rather than software management.

Beyond usability, the platform’s accessibility was a decisive factor. By offloading the heavy computational lifting to the cloud, SimScale allows the team to run complex parallel simulations from standard laptops, eliminating the need for expensive on-premise workstations. Jiří describes SimScale as the “most optimal” solution for their needs, combining high-end performance with cost-effective scalability.

“Anytime I need something I reach out to technical support, and they are very responsive. That helped a lot to get up and running quickly, and continues to save time and effort when we are looking into new areas of modeling”

Jiří Hlaváček

Development Engineer, TEGnology

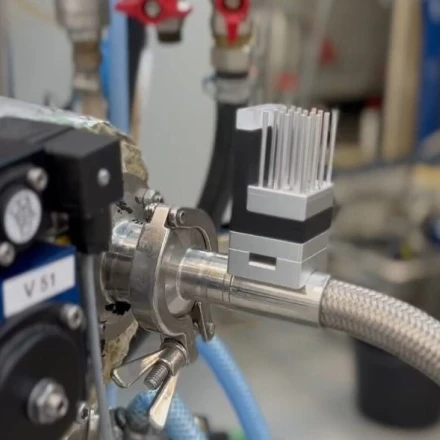

The focal point of TEGnology’s recent engineering efforts is the SensEver HSI BLE (Hot Surface Indicator – Bluetooth Low Energy). This dual-purpose device provides a visual safety alert (a blinking light) when a pipe is dangerously hot and simultaneously transmits precise temperature data wirelessly.

For Jiří, the ultimate objective of simulation is straightforward: “To develop a good enough digital twin that will accelerate our development by allowing us to eliminate physical testing.” However, achieving this fidelity in a virtual environment presented significant modeling hurdles. The most critical was the issue of contact resistance. In thermal engineering, the interface between two metal parts is never perfect; microscopic gaps create resistance that blocks heat flow.

“If you connect two metallic parts in simulation, you need to know what the contact resistance is between those two surfaces” explains Jiří. If these resistances were ignored, the simulation would predict a higher power output than physically possible. To bridge this gap between the virtual and real worlds, Jiří used SimScale’s thermal analysis software to meticulously tune the contact resistance parameters in his models, correlating them against physical lab measurements. This rigorous process allowed TEGnology to build a proprietary library of validated thermal interface values, enabling them to predict how different thermal pastes, surface finishes, and clamping pressures will affect performance without needing to manufacture a prototype for every iteration.

Looking to simplify their product catalog and customer experience, TEGnology wanted to develop a product that could be attached to any size of pipe, without needing to match the shape of the clamping surface to that of the pipe wall.

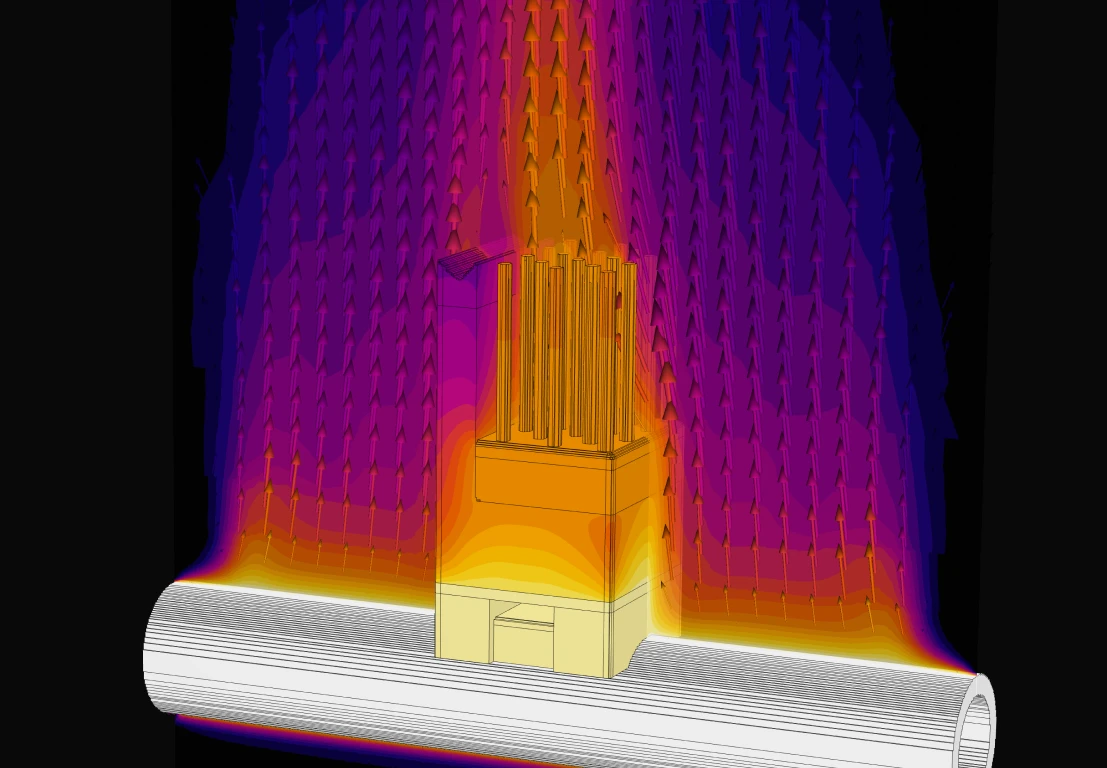

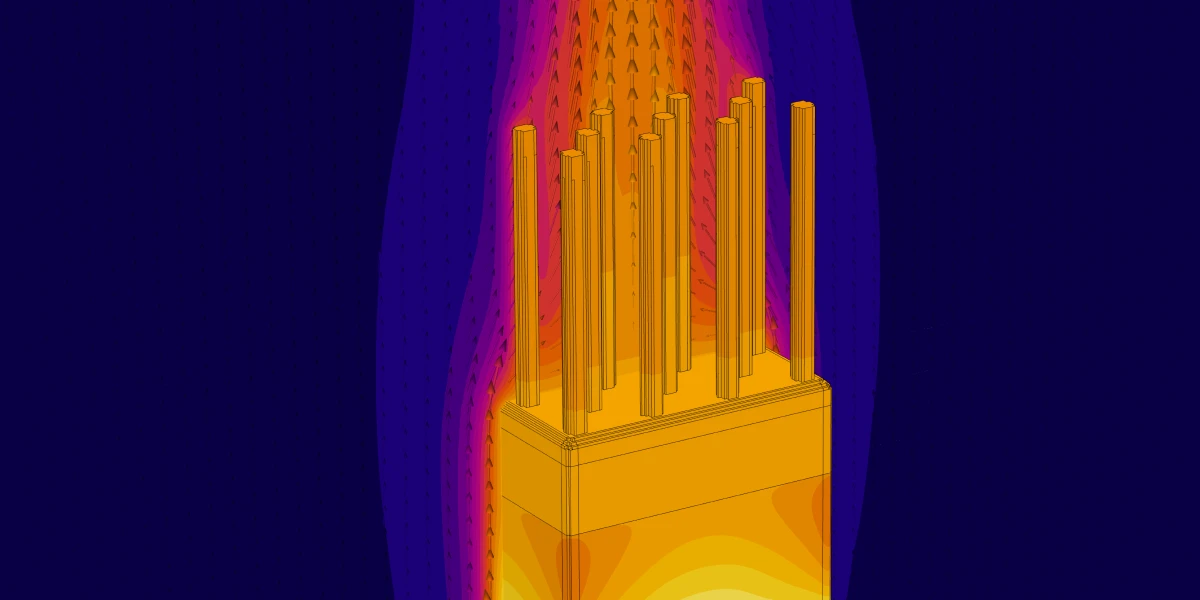

A key innovation for the HSI BLE was the development of a universal V-shaped adapter designed to fit pipes of various diameters. While versatile, this design brings new challenges by creating a “line contact” with the pipe, significantly reducing the surface area available for heat transfer.

Through simulation, the team visualized the thermal constriction caused by this design. The analysis quantified exactly how much high-performance thermal paste was required to ensure reliable operation, proving that the device could harvest enough energy despite the geometric mismatch. This insight enabled the commercial launch of a versatile product that simplifies inventory for customers without compromising reliability.

Simulation also provides a physical basis on which to calibrate temperature measurements. “The challenge is that the sensor is not directly on the pipe surface, but higher up in the housing”, Jiří explains, “so we need to know what the temperature differences are through the housing to determine what that offset should be.”

The team could use insights from Conjugate Heat Transfer (CHT) analysis to see how the temperature offset was created within the assembly and to refine the correction algorithm that they had developed through lab testing. This “back-calculation” is crucial to delivering accurate temperature data to the end-user.

SimScale has transformed TEGnology’s development cycle, shifting their approach from iterative design and physical testing to simulation-driven design, saving “significant amounts” by reducing physical prototyping.

“We developed a digital twin methodology by correlating CFD results with laboratory testing – building up a library of contact resistance values for different materials and surface treatments. Now we can explore new design territory in simulation without needing to go back to the lab, which has transformed our NPD process”

Jiří Hlaváček

Development Engineer, TEGnology

Simulation with SimScale has also transformed the way the company engages with customers, too. Now, the team can prove out specific deployments by simulating a customer’s specific environment, such as unique pipe diameters or marginal temperature ranges. This “virtual commissioning” approach allows them to validate energy yield before a sale is even made.

Looking forward, TEGnology plans to expand their simulation scope to include additional physics such as Joule heating to drive new product development and further refine their industrial edge solutions. By leveraging the power of cloud simulation, TEGnology continues to drive the adoption of sustainable, self-powered monitoring across the industrial landscape.

Set up your own cloud-native simulation via the web in minutes by creating an account on the SimScale platform. No installation, special hardware, or credit card is required.

Sign up for SimScale

and start simulating now