Yamaichi Special Steel offers a broad range of services, providing a variety of Special Steel, fabricating high-precision parts for production tools and molds, and specializing in advanced manufacturing technologies such as additive manufacturing for engineering metal, plastics, and silicone rubber.

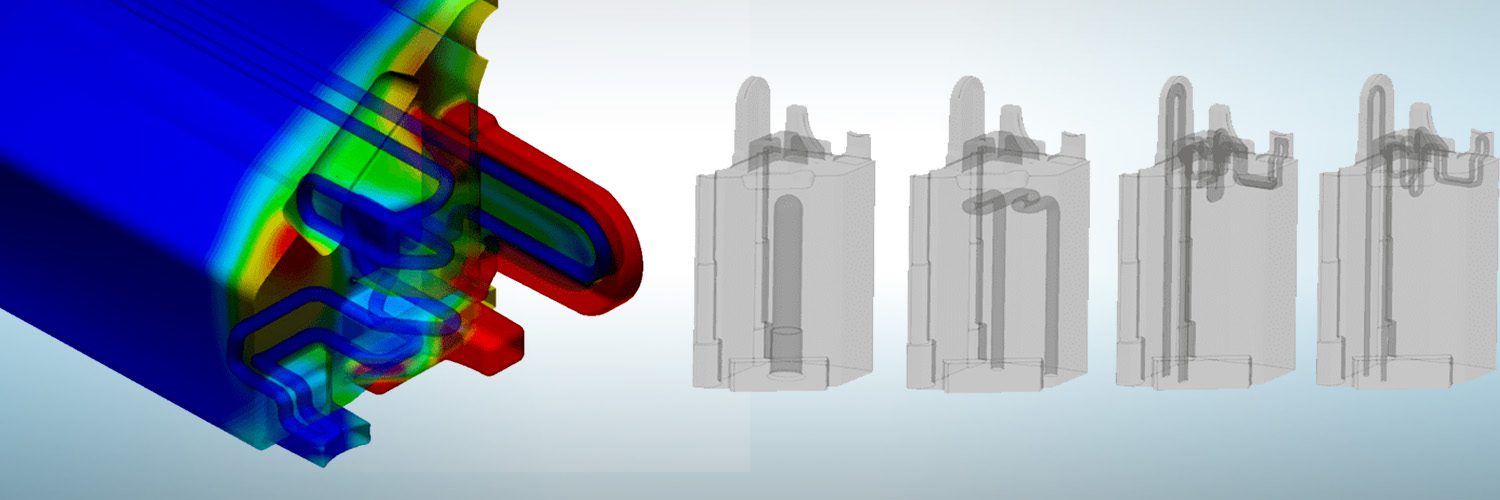

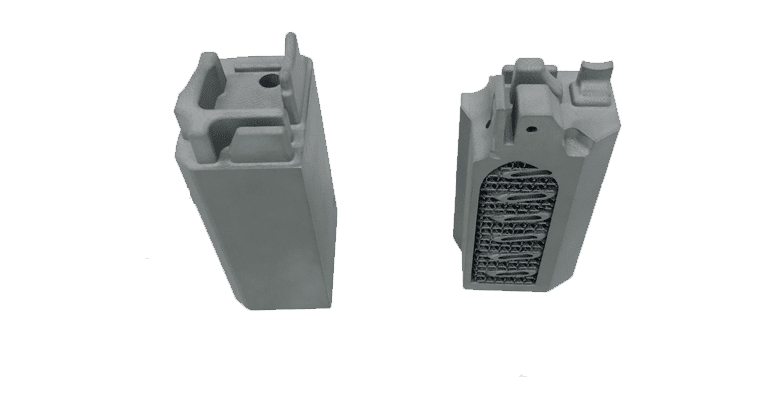

As there is a high demand for additive manufacturing in the automotive mold market for conformal cooling channels design, there were a number of goals in this case study. These objectives included but were not limited to, achieving faster mold prototyping, production lead time reduction, casting/injection cycle time reduction, and producing higher performant molds.

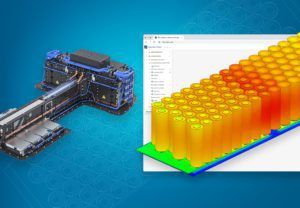

In order to evaluate the mold’s cooling channel performances directly at the design stage for closed-loop design, Yamaichi Special Steel turned to CAE to reduce developmental costs and overheads.

Carrying out the design process for additive manufacturing requires knowledge in many fields. While most jobs can be completed digitally by one person, an engineer is responsible for all stages of product development; innovative part design, topology, optimization, mechanical and thermal validation, industrialization, product preparation, and so on.

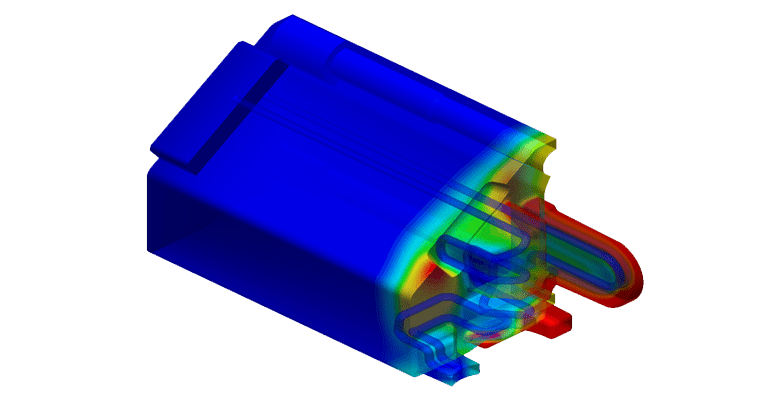

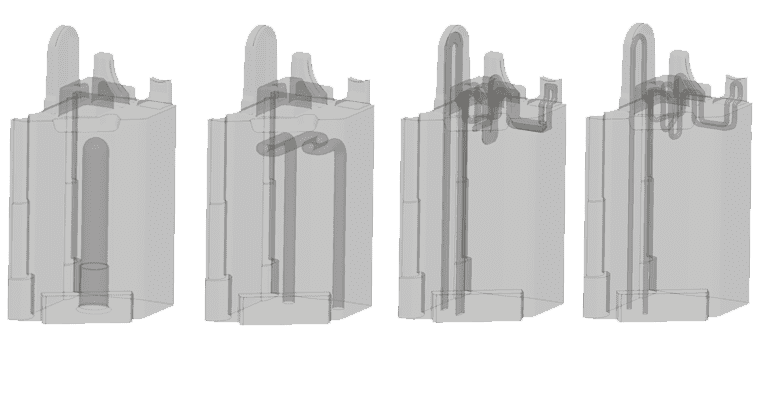

Large amounts of hardware and software are naturally needed to carry out these tasks, and shifting between each can be troublesome. By using SimScale, Yamaichi Special Steel was able to keep simulation parameters and easily swap the geometry for different design iterations, in turn allowing for direct design validation. Moreover, the cloud-native platform allowed the team to easily collaborate on one project.

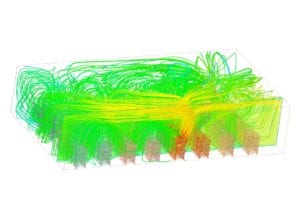

The design of conformal cooling channels requires a lot of iterations, and often project and production lead times are very short.

Yamaichi Special Steel needed an efficient time-dependent simulation, and a smart method of performing a CFD analysis of the metal and cooling water flow to gain results that would lead to the next stage of the development process−SimScale provided this. Yamaichi Special Steel continues to work with SimScale on additional design tests and evaluations.

With the Simscale Team, we could make a simplified simulation model simulating the injection and cooling time with heat flux. The simulation is not 100% accurate with reality but represents kind of the “worst-case scenario”, which was perfect for our needs.

Henri de Charnacé

Engineer

Sign up for SimScale

and start simulating now