Oxygen8, headquartered in North America, delivers fully electric, high-efficiency HVAC and DOAS (Dedicated Outdoor Air System) solutions for commercial and residential applications. Their mission is to provide healthy indoor environments while reducing energy consumption and operational emissions.

As a product innovation leader, Oxygen8 has embraced simulation as a key enabler of faster development, better performance, and cost-effective design iteration.

Oxygen8 is redefining how energy-efficient ventilation systems are designed and delivered. With a strong focus on sustainability, indoor air quality, and energy optimization, the company is leveraging SimScale’s cloud-based engineering simulation platform to accelerate the design and validation of its next-generation air handling units (AHUs). Their latest development, the Terra V system, showcases how CFD simulations helped optimize airflow distribution, improve heat transfer across coil surfaces, and eliminate inefficiencies in early-stage designs. This was done with only one prototype iteration to validate the simulation and physical performance.

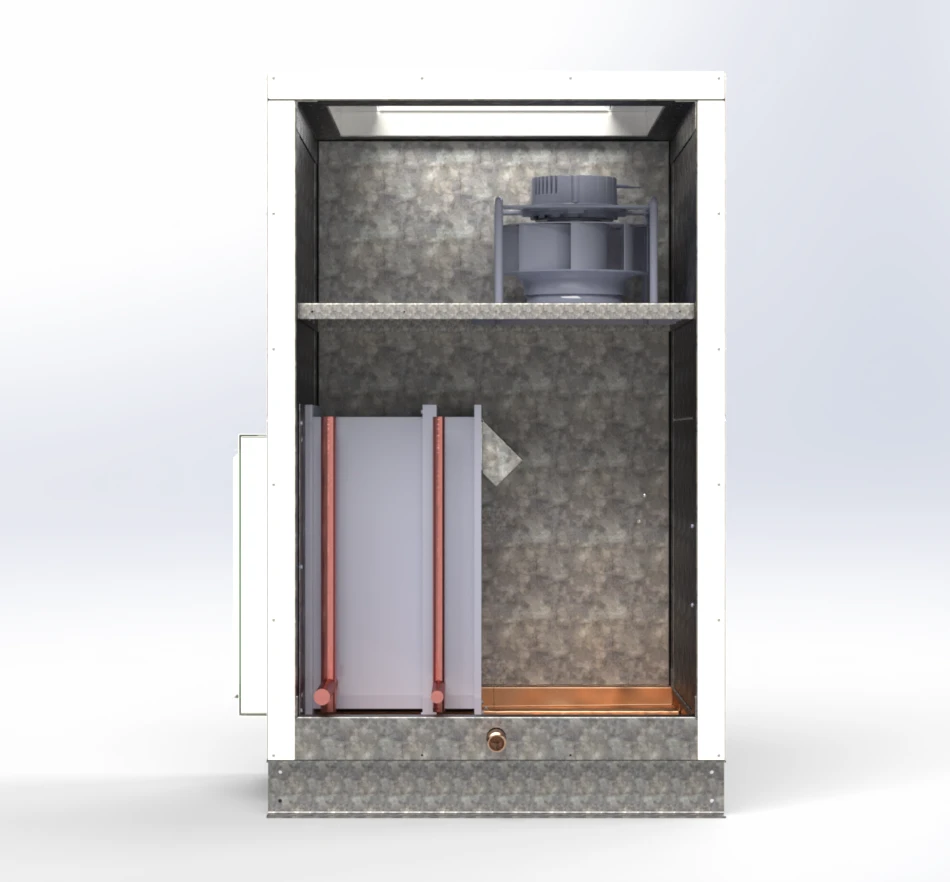

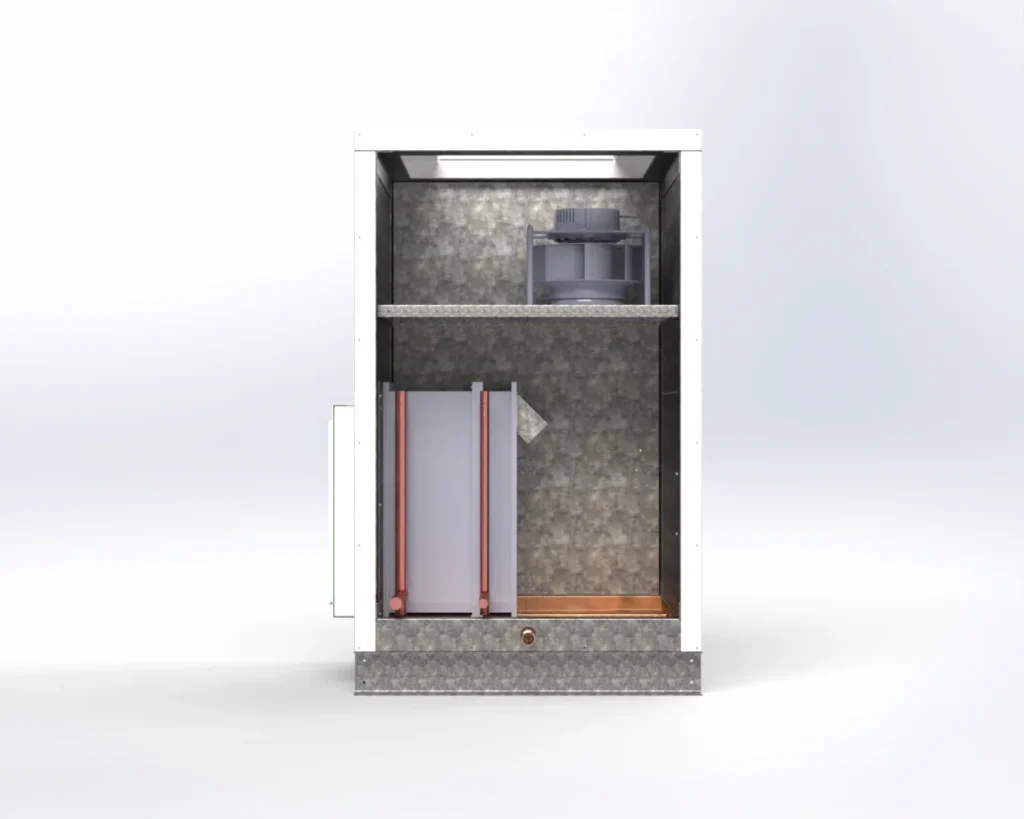

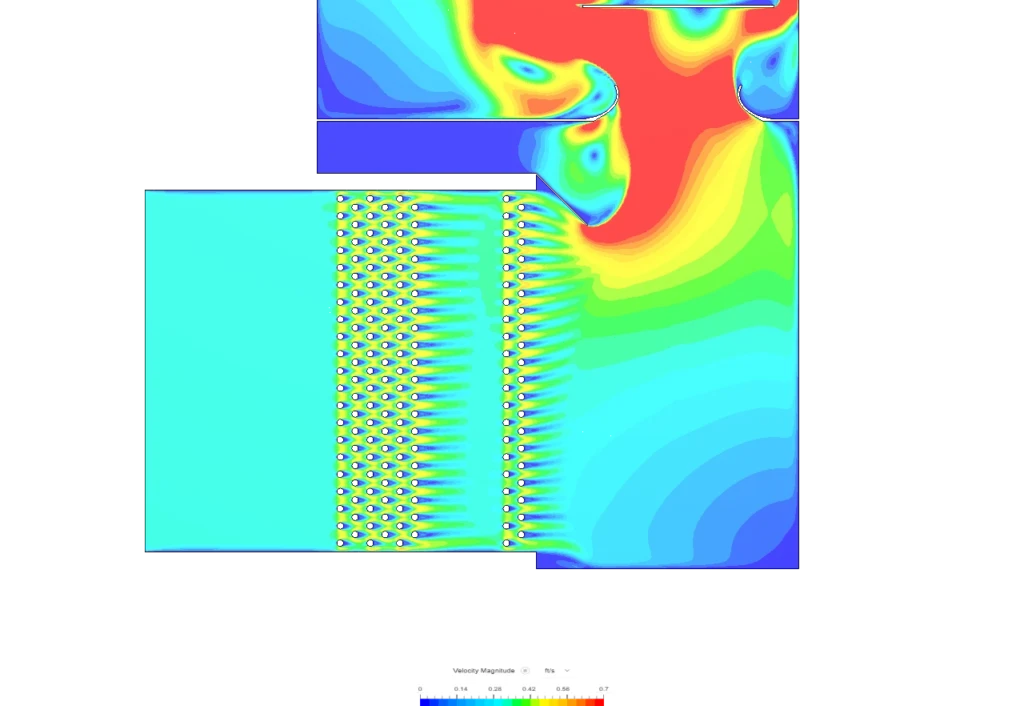

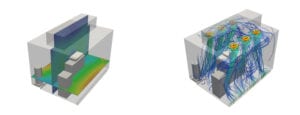

The Terra V is a compact, base-mounted air handling unit designed for retrofits and space-constrained installations in commercial buildings. It features chilled water cooling, direct expansion (DX) coils, hot gas reheat, and ECM direct drive fans supplying a range from 450 to 10,000 CFM. In this configuration, air enters from the side, flows through a series of thermal coils, passes a fan section, and exits from the top into the ductwork. Oxygen8 used SimScale to simulate and refine the internal airflow of the Terra V system. Key goals included ensuring uniform face velocity across the coil surfaces for effective heat transfer and verifying that fan pressurization led to smooth, non-turbulent supply air discharge.

Using models imported from SolidWorks, the Oxygen8 team first conducted CAD cleanup to prepare simulation-ready geometries. CFD simulations were then configured in SimScale, using a pressure inlet boundary and velocity outlet condition to target supply air velocity values. Cooling coils were modeled both geometrically and with porous media approximations to compare accuracy and simulation efficiency.

Specific objectives of the Terra V simulation included:

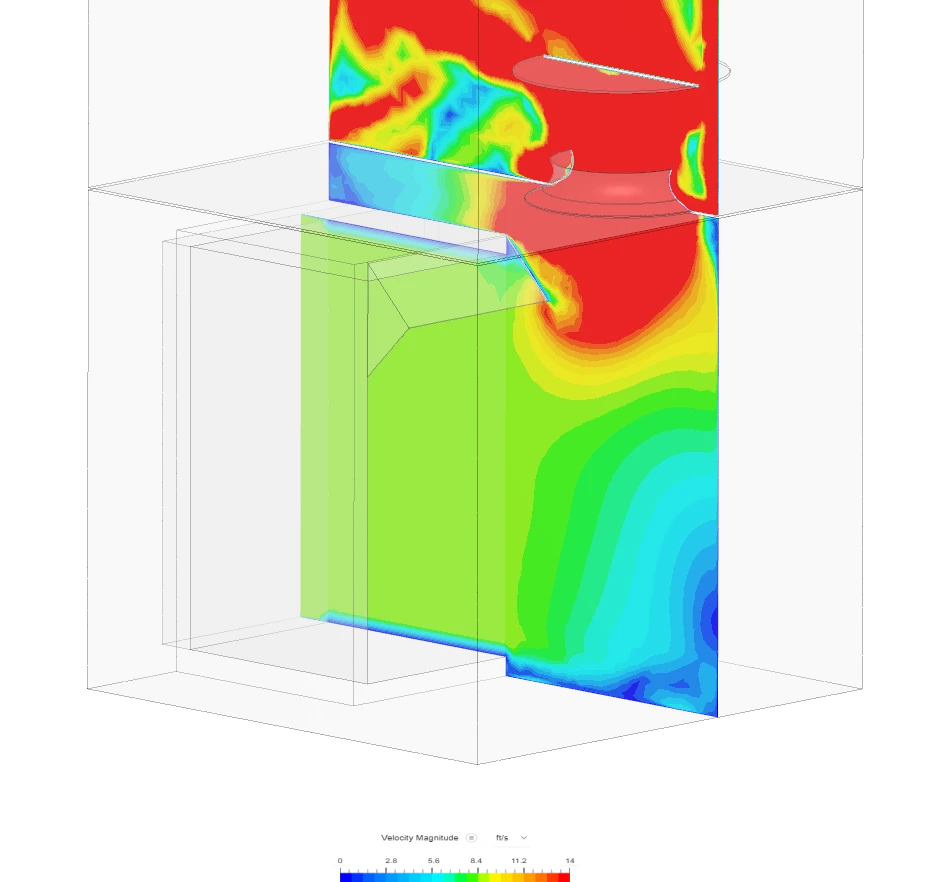

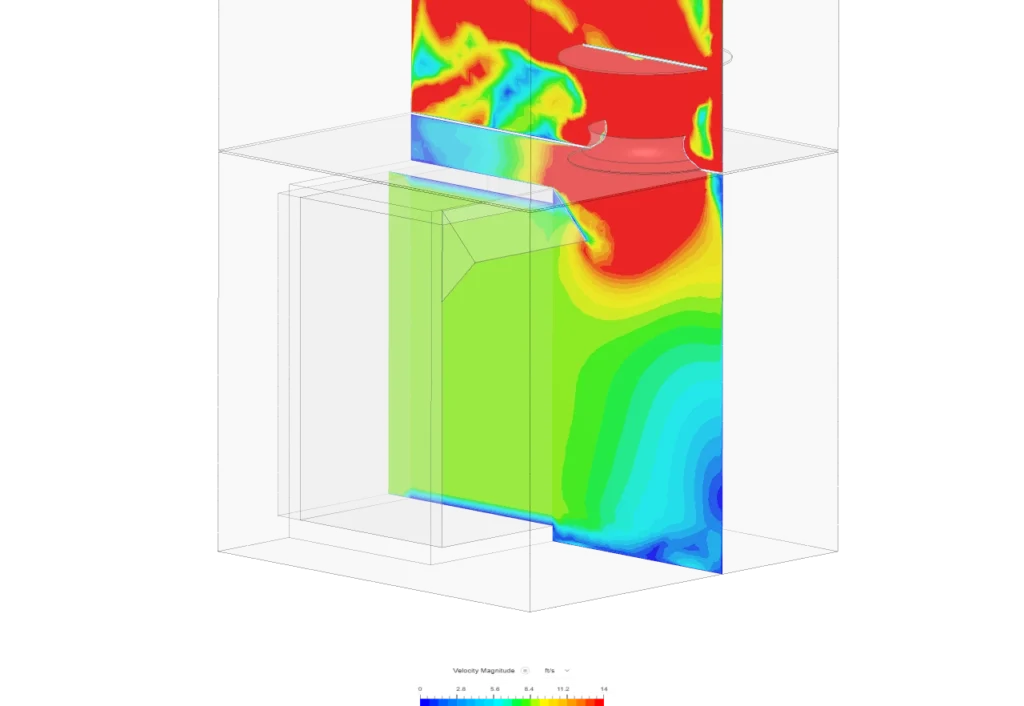

Initial simulations revealed regions of recirculation and uneven flow across the coil face. This would have resulted in suboptimal heat transfer, risking performance degradation and potential comfort issues in end-use installations. By iterating within SimScale, Oxygen8 was able to redesign internal baffles and adjust component placements to flatten the velocity profile across the coil surfaces.

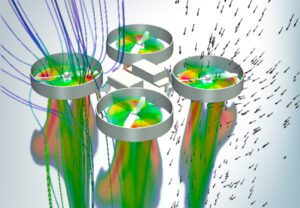

With refined internal geometry, later simulation runs showed significantly more uniform velocity distribution. Streamlines demonstrated smoother transitions through the coil region and into the pressurized plenum above the fan. Supply air flow was consistent with design targets, ensuring reliable performance and optimal thermal exchange without over-sizing components.

Rendered CFD visualizations helped communicate simulation results to cross-functional teams, reinforcing the engineering decisions made during design iteration and for compliance with ASHRAE standards.

While CFD was the primary tool used, Oxygen8 also employed SimScale’s FEA functionality to optimize sheet metal thickness for structural integrity and manufacturing cost savings. Gauge thicknesses for base-rails and support brackets were evaluated against loading conditions using static stress analysis.

Ethan Quisias, one of the lead product development engineers at Oxygen8, noted that while he had previous experience using ANSYS, SimScale offered a more accessible and faster workflow, allowing the team to explore more design options with less friction.

By adopting SimScale as a core design and validation tool, we have reimagined how ventilation systems are developed. From rapid concept evaluation to final optimization, cloud-native simulation enabled faster iteration, better decision-making, and superior product performance during the entire development process. The Terra V is a prime example of how simulation can eliminate costly guesswork and accelerate the delivery of high-performance HVAC solutions to market. The simulations were used as the decisive factor in determining geometry and layout.

Ethan Quisias

Product Development Engineer at Oxygen8

The integration of SimScale into Oxygen8’s design workflow yielded several critical benefits:

Ethan and the engineering team now use SimScale for continuous improvement projects across multiple products, with a growing focus on CFD and FEA to support innovation.

Sign up for SimScale

and start simulating now