Founded in 1864 in Olpe, Germany, Kemper is a family-run market leader driven by deep technical expertise. The company philosophy is “Driving Progress”, as evidenced by their evolution from a metal foundry into a global player with sites from the UK to Singapore. Kemper’s Building Technology division applies the same approach to the design of valves and sanitary water systems, in which water must be kept flowing to prevent pathogen growth and maintain water safety.

Kai Günther is a Mechanical Engineer in the Building Technology division. With experience in simulation from previous roles, Kai is responsible for assessing the hydraulic efficiency of design candidates to support the new product development process. The company uses simulation with SimScale to virtually develop and test prototypes to accelerate design cycles and reduce spend on 3D-printed physical prototypes.

Simulation is essential to Kemper’s development process, allowing the team to compare different design geometries early in the cycle. The goal is to identify performance trends—determining if one design offers better flow characteristics than another—before committing to physical manufacturing. While Kemper has internal resources for 3D printing, the physical verification process is costly and slow. Producing a single prototype involves printing the component in stainless steel and then machining the sealing surfaces, often requiring the fabrication of custom clamping fixtures. This physical cycle takes up to three weeks per iteration, creating a significant bottleneck.

For Kai Günther, a mechanical engineer at Kemper, the transition to SimScale was driven by a need to democratize this simulation capability. Previously, the department relied on a CAD-embedded solution, but the workflow was restrictive. The software required a dedicated, heavy-duty workstation that tethered engineers to a single desk and locked up resources during calculations. “We searched for something that was easy to learn for colleagues who are not experienced with CFD simulation,” Kai explains.

Beyond accessibility, the legacy tool struggled with the team’s “dirty” CAD geometry. Preparing a model for simulation required Kai to spend up to an hour manually closing gaps and fixing sealing surfaces to create a watertight fluid volume. The team needed a solution that was not only browser-based and scalable but robust enough to handle complex assemblies without hours of pre-processing. After benchmarking several solutions, SimScale emerged as the clear winner due to its user-friendly interface and the power of its solvers.

“We estimated that physical prototyping takes at least two or more weeks, so an iteration in SimScale is a lot faster… a design comparison takes about one day.”

Kai Günther

Mechanical Engineer, Kemper

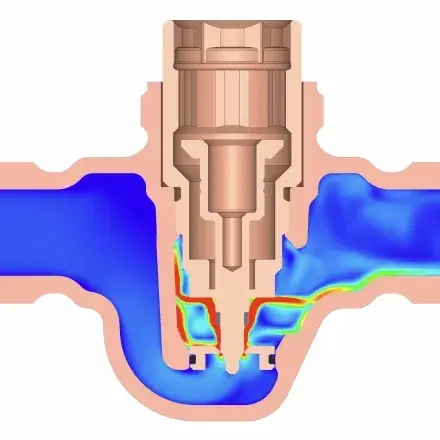

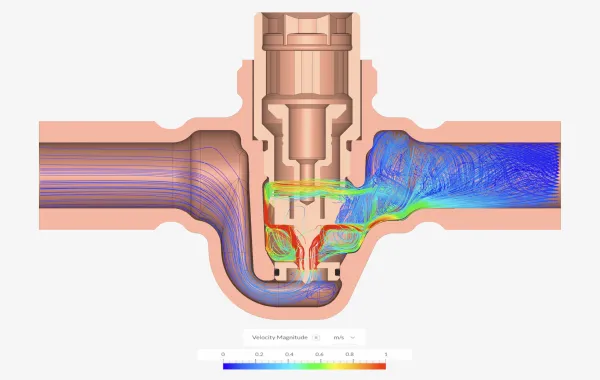

The capabilities of the new platform were tested on the ETA-THERM, a thermostatic balancing valve designed to regulate hot water circulation systems. The valve operates dynamically, adjusting its flow resistance based on water temperature to ensure that hot water is available at every tap in a building immediately.

The engineering challenge lay in the valve’s “regulated” position. In this state, the valve is nearly closed, leaving a very small gap for water to pass through. “We always had problems modeling that condition using our CAD-embedded tool, the results were quite some way off” Kai notes regarding their previous software. The legacy solver could not accurately resolve the fluid dynamics in these tiny spaces, often producing unrealistic values or failing to converge entirely.

Using SimScale, Kai was able to simulate the flow through these sub-millimeter gaps without needing to spend time manually redesigning the CAD model to be watertight. “We initially established the accuracy of SimScale by running a blind benchmark against physical lab data, and the results almost perfectly matched”, Kai recalls. With a reliable simulation process in place, the team could progress in their aim to eliminate the expensive physical prototyping that has previously limited their engineering velocity: “This built confidence in the workflow and the Subsonic Analysis in SimScale, so we can now lean into to simulation more heavily”.

The adoption of SimScale has collapsed Kemper’s design iteration time from three weeks (for 3D printing and machining) to just one day. Looking forward, the team plans to expand their use of simulation beyond simple performance verification. Plans are in place to use SimScale for optimizing the integration of vortex and temperature sensors within valve bodies, ensuring that measurement instruments do not disrupt the hydraulic balance. By building a digital library of these simulations, Kemper is also securing institutional knowledge, ensuring that the engineering reasoning behind every design is preserved for future generations.

Set up your own cloud-native simulation via the web in minutes by creating an account on the SimScale platform. No installation, special hardware, or credit card is required.

Sign up for SimScale

and start simulating now