Griffon Hoverwork is a world leader in hovercraft design and manufacturing of hovercraft and has been involved in hovercraft development since they were first conceived, over 50 years ago. The company develops pioneering new products and solutions and offers expert advice, training, and consultancy. Over 180 Griffon Hoverwork craft operate in 41 countries, in extremely inaccessible and challenging environmental and geographical conditions. Griffon customers all have one thing in common — a need to access areas where conventional marine craft cannot operate. A core capability in designing and manufacturing hovercraft which are adapted to challenging environments is the use of simulation to virtually test and optimize craft performance.

Hovercraft developed at Griffon can be customized to meet different mission and environmental conditions. They are used for various purposes, including:

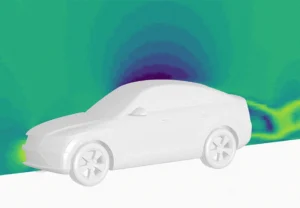

At Griffon Hoverwork, CFD simulations are an essential part of the product development process given the critical usage of these craft for essential services. By simulating key components such as the propulsion system, the team at Griffon gains valuable insights that directly influence the design and performance of the hovercraft.

“A Hovercraft is a fascinating vessel, blending naval, aero, mechanical, and electrical engineering, so working on hovercraft at Griffon Hoverwork presents a unique and exciting real-life engineering challenge. I recently joined Griffon Hoverwork as a Graduate System Design Engineer. My current work involves conducting Computational Fluid Dynamics (CFD) analysis using SimScale on critical systems of a hovercraft, and performing essential design calculations such as structural loading.”

Ayano Maeda

Systems Design Engineer at Griffon Hoverwork

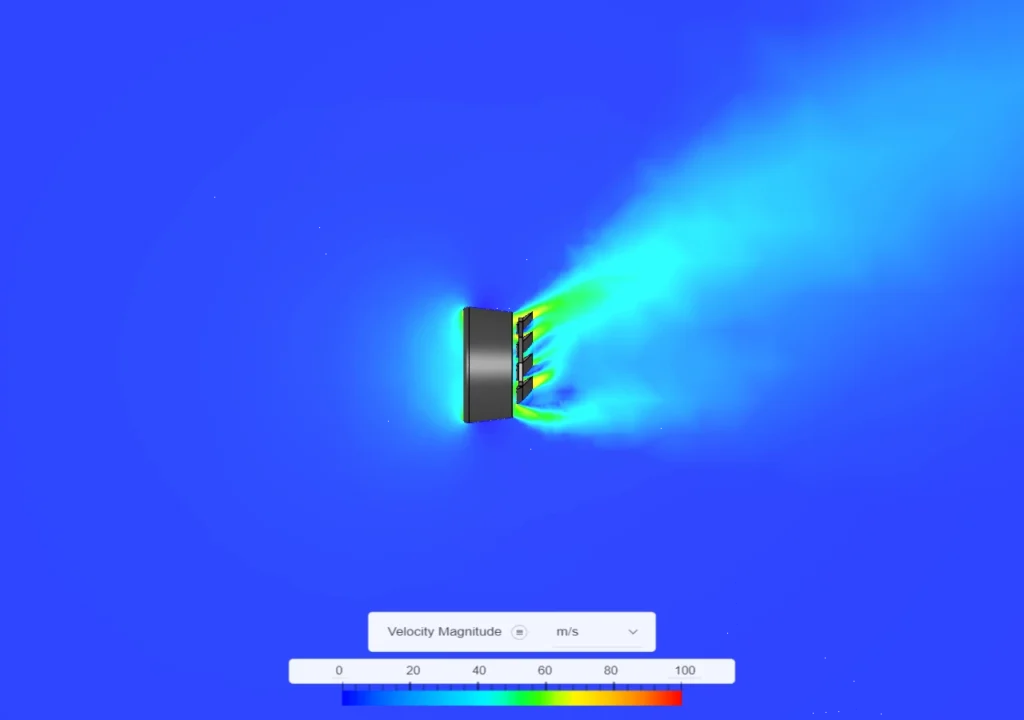

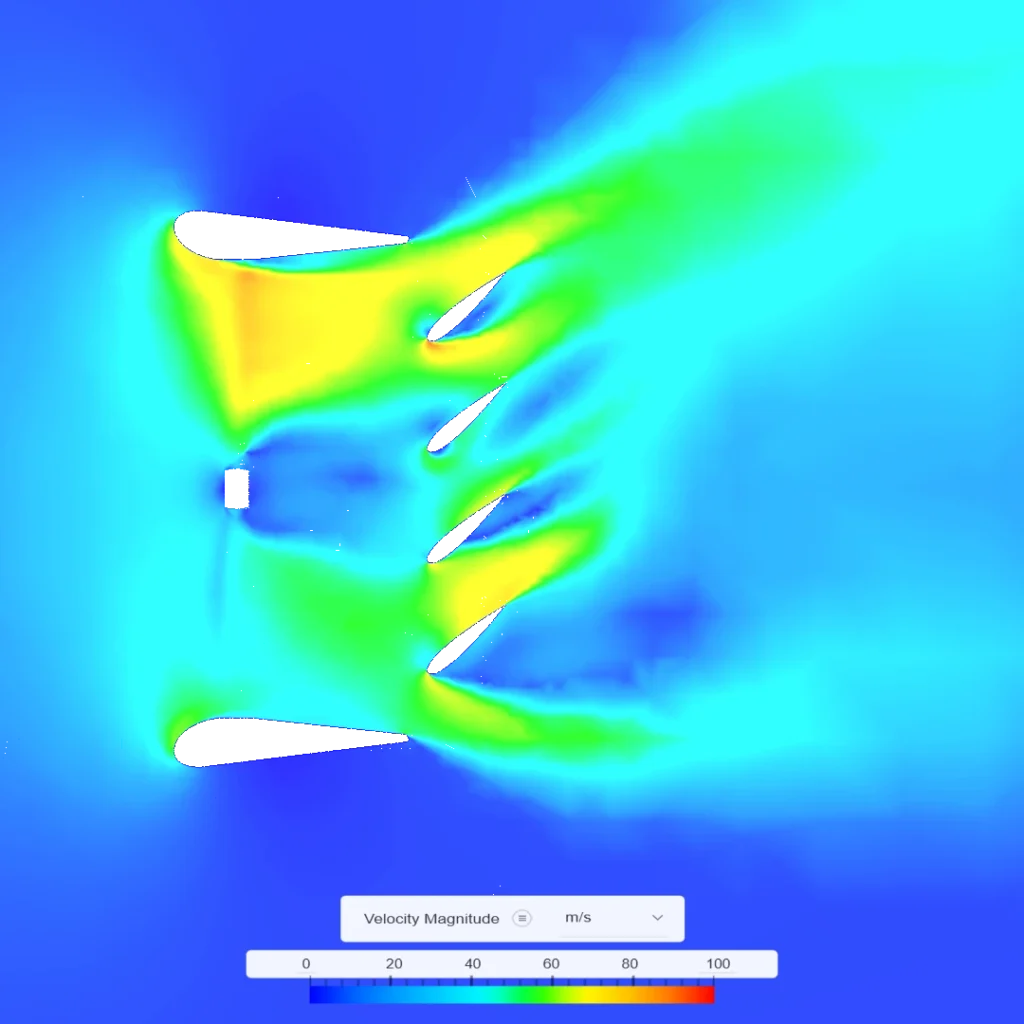

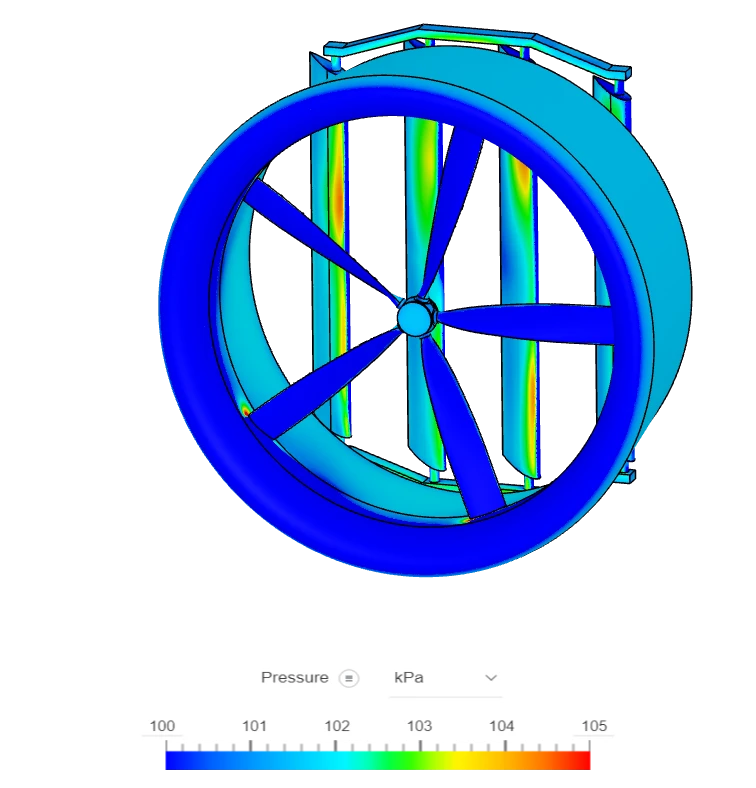

This simulation example below represents the main propulsion system on a type of hovercraft to scale. The propulsion system consists of a propeller, duct, and rudder (4 aluminum blades in cascade setup). The primary objective of this simulation was to determine the load on each rudder blade. This data is crucial for:

“Using SimScale has given us many advantages in product development. It has resulted in significant cost and time savings achieved by reducing the need for physical testing, which requires expensive components, labour and specialised facilities. The component CAD model we have can be easily changed and re-simulated in SimScale. Given the cloud-native nature of SimScale, there is no limit to the number of simulations of competing CAD variants that can be run. Since our simulations were run for a range of operating conditions, parametric boundary conditions were used. This would have been more challenging on a local computer due to limited processing power. However, the cloud-based nature of SimScale allowed us to adjust the computational resources as needed, making the simulation process more efficient. I also found that the robust auto-meshing capabilities in SimScale significantly reduced meshing time and thus simulation set-up time and, the collaboration features in the SimScale platform allowed us to seamlessly talk with the support team in the live simulation project environment.”

Ayano Maeda

Systems Design Engineer at Griffon Hoverwork

Sign up for SimScale

and start simulating now