Hydrogen is a highly versatile industrial gas and energy carrier, essential for storing and delivering energy as well as serving as a key building block in a wide range of heavy industries and processes.

Versogen’s breakthrough electrolyzer technology produces green hydrogen at scale using only water and renewable energy. Built around patented PiperION® anion exchange membranes (AEMs) and earth-abundant materials, these systems offer a cost-effective, sustainable path to decarbonization. Versogen’s hydrogen-generating solutions are engineered to significantly reduce industrial carbon emissions and form the backbone of a clean energy future. Designed for the renewables, these electrolyzer stacks respond seamlessly to intermittent power from wind and solar sources, ensuring flexible and resilient hydrogen production.

Versogen’s patented PiperION® platform is setting the industry benchmark for anion exchange membrane (AEM) technology. With manufacturing scaled to support 1 gigawatt per year, PiperION® membranes are enabling breakthrough performance in hydrogen electrolyzers, fuel cells, carbon capture, and carbon conversion systems.

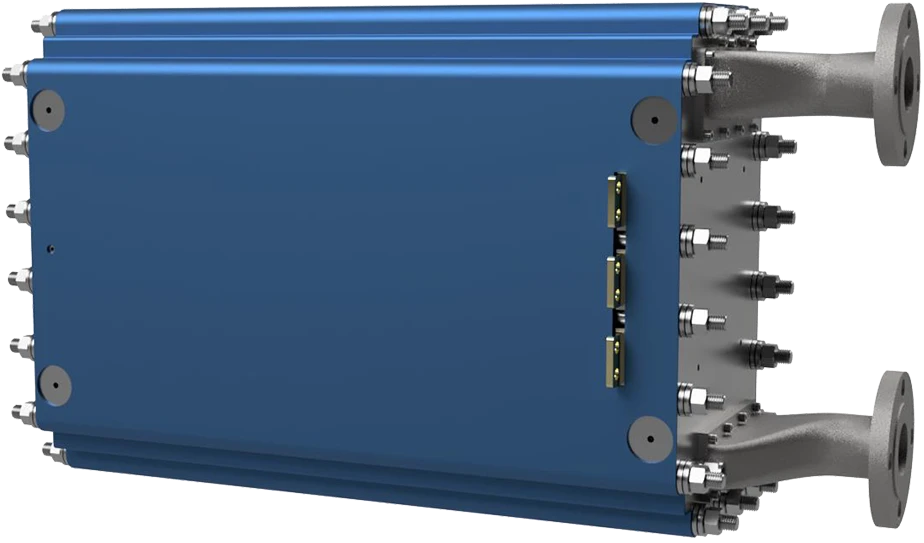

Taking advantage of its strong foundation in membranes, Versogen offers industry-leading stack design to deliver unmatched efficiency, durability, and cost-effectiveness in alkaline environments. This cutting-edge design powers Versogen’s 300 kW electrolyzer stack, now available for licensing, offering a scalable solution for clean hydrogen production across industries.

Notably, Versogen’s AEM stack has already exceeded the U.S. Department of Energy’s 2026 performance targets, further cementing PiperION® as the premier AEM stack on the market today.

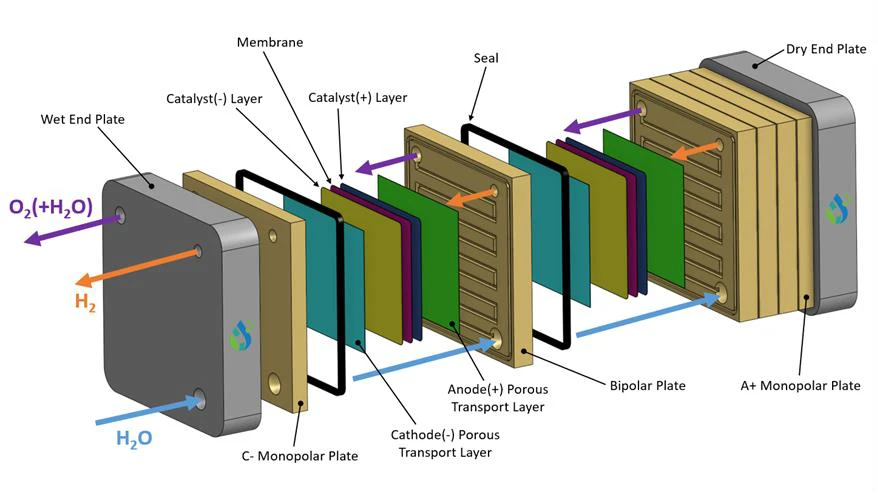

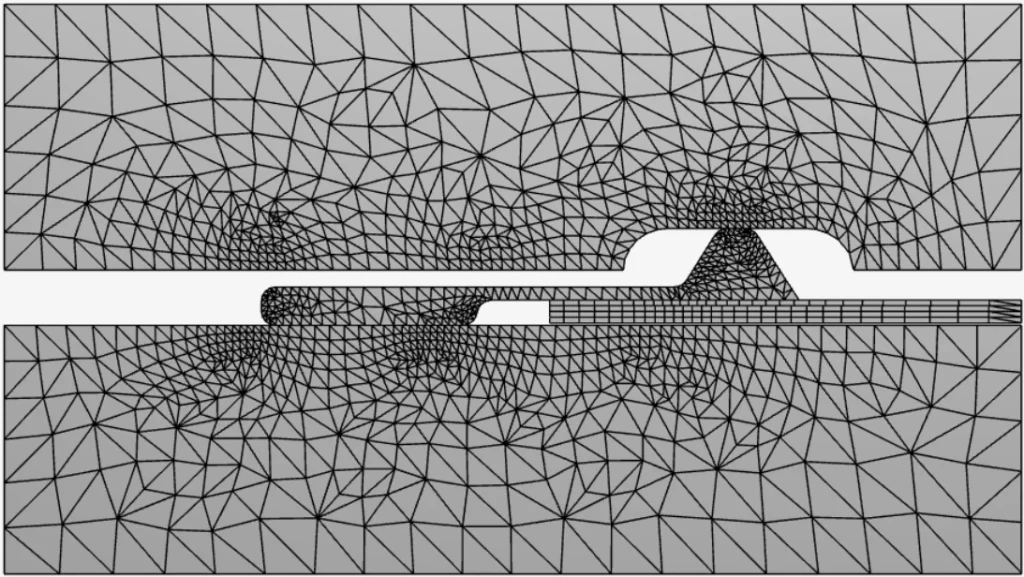

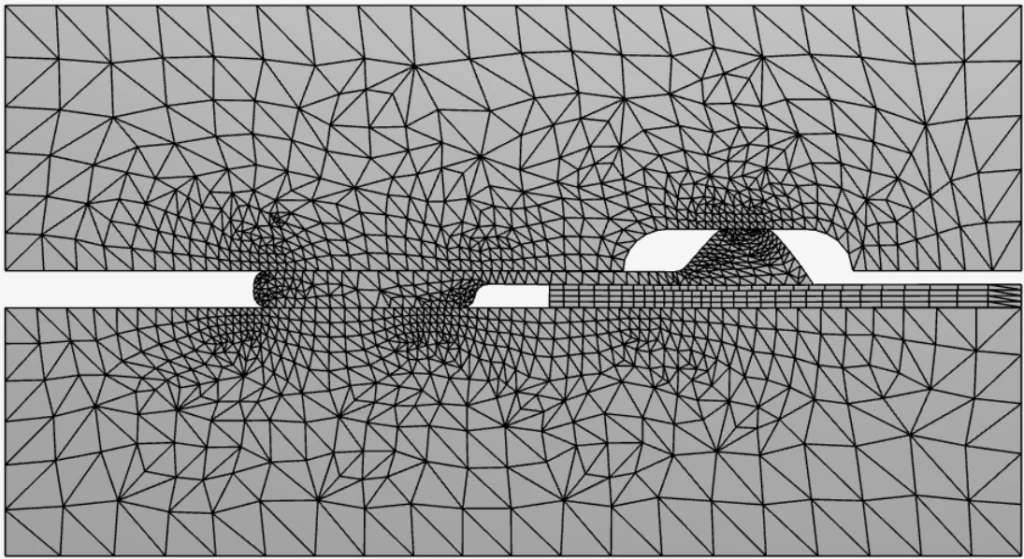

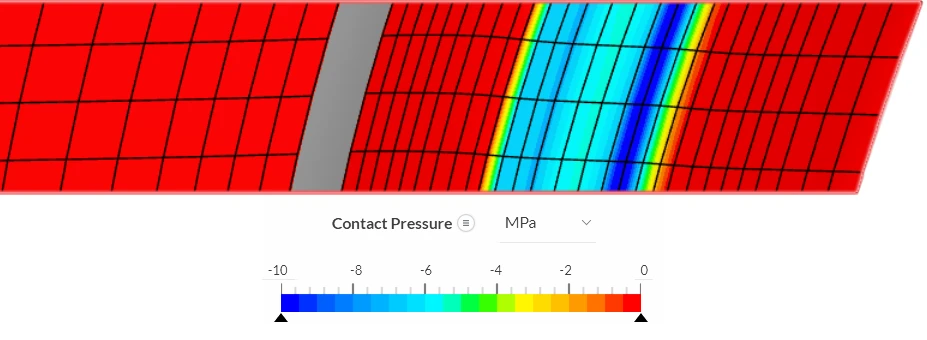

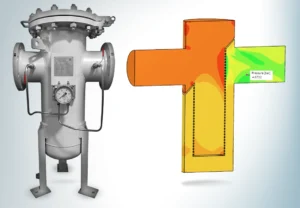

The team at Versogen has been using SimScale to design and test the performance of its electrolyzer stacks, specifically using CFD and FEA solvers for flow analysis and structural optimization. The electrolyzer stack shown above has a high-performance proprietary seal that must perform for the overall device to function at high efficiency.

The elastomeric seal from a single-cell stack is simulated with compressive loads applied to it from both sides (Solid and fluid). The stack contains many elements, including membranes, diffusion layers, seals, bipolar flow plates, and catalysts, and must be simulated in detail for precise calculations. The purpose of the seal is to stop leakage of water and H2 into the atmosphere and to make sure there is no H2 leakage at 35 Bars pressure to the O2 side.

The use of simulation in the cloud has been a huge benefit for a high-tech startup like Versogen. We have a distributed team of engineers working on some of the most promising decarbonization technologies globally. The fact that we can access high fidelity simulation whenever we need it means our aggressive product development strategy is never compromised by simulation lead times or unavailable compute resources. Simulating electrochemical energy conversion devices can be complex and we have found SimScale is always adding new physics or features to facilitate flow, thermal and mechanical studies that we are reliant on.

Balsu Lakshmanan, Ph.D.

Chief Technology Officer at Versogen

Sign up for SimScale

and start simulating now