The European Gravitational Observatory (EGO) was established in 2000, tasked with detecting gravitational waves – faint whispers from the universe’s most cataclysmic events. It is one of only four such facilities in the world and the only one in Europe.

EGO’s ear to the cosmos is the Virgo detector, a colossal laser interferometer near Pisa, Italy. Its two arms, each three kilometers long, are designed to sense a passing gravitational wave as a distortion in spacetime smaller than one ten-thousandth of a proton’s diameter. This almost unimaginable sensitivity necessitates a “cascade of precision” where every component must perform at the absolute limit of engineering.

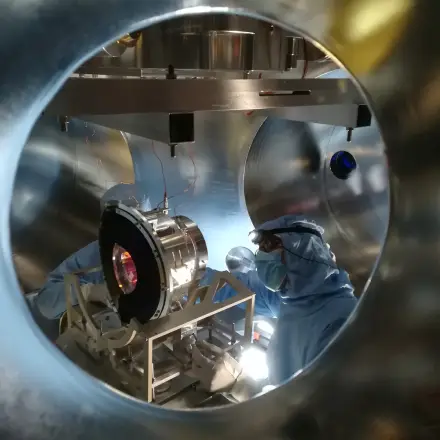

Virgo’s ability to detect the passing of a gravitational wave depends on the perfect function of the optics and mirrors, polished to near-atomic flatness. In this environment of ultimate precision, the greatest threat is microscopic contamination. A single dust particle landing on a mirror’s surface can scatter light or absorb energy from the high-power laser, creating a localized hot spot that could cause irreversible damage and blind the detector. Beyond solid particles, molecular contaminants pose another severe risk, forming thin films that degrade performance over time. This makes absolute cleanliness a non-negotiable, mission-critical requirement, demanding an environment that meets the stringent ISO 5 standard, typically reserved for the semiconductor industry.

The Virgo detector operates inside one of Europe’s largest ultra-high vacuum (UHV) systems to prevent scattering of the laser beams. The moment of greatest vulnerability therefore occurs during periods of maintenance or upgrades, when these chambers must be opened to carry out work inside. After they are carefully vented with clean air, the risk arises when personnel and equipment enter, inevitably introducing contaminants into the pristine environment. The way to mitigate this risk is to design the chambers to operate as cleanrooms with highly effective air flushing systems, continuously ‘washing’ the interior with a curtain of ultra-pure air which safely removes dust particles before they can settle on surfaces or optical equipment.

The continuous evolution of the Virgo detector is part of a global effort to enhance the sensitivity of the gravitational wave network. EGO operates in upgrade cycles of four to five years, during which the detector is taken offline for significant enhancements. The current upgrade cycle involves adding eight new, smaller vacuum chambers and reconfiguring existing ones, triggering a critical infrastructure project to design the new chambers and their HVAC systems which maintain a cleanroom environment inside.

Leading this crucial design effort is Julien Gargiulo, a Vacuum Engineer at EGO. His journey into the world of high-physics experiments began with a mechanical engineering degree in France, specializing in material science and simulation. Early CFD experience in the steel industry was followed by a role at CERN, where he was immersed in the world of large-scale vacuum systems. It was there, working with the vast underground accelerators, that he became involved in vacuum engineering. “I came to appreciate that vacuum is not simply “nothing,” but a demanding engineering environment,” Julien remarks. At EGO, his role is varied, covering everything from material analysis and 3D modeling to hands-on operations on the detector itself. This project required him to deliver a robust airflow system that could ensure ISO 5 cleanroom conditions while coping with a range of internal blockages from people and equipment moving around inside.

Recognising the importance of capturing existing operational know-how to inform design direction, EGO intended to bring simulation expertise in-house, to gain control over the design process and move away from relying solely on the expertise of external contractors. Julien sought an in-house online CFD simulation tool. Having previous experience of resource-hungry desktop software, he made a strategic decision to look at cloud solutions and chose to adopt SimScale for its unique advantages. “It’s way more user-friendly,” Julien notes, “in the sense of finding options, managing the models and changing setups. It’s much easier to handle.”

The intuitive, cloud-native platform empowered Julien, a domain expert rather than a full-time analyst, to run his own simulations without needing powerful local hardware. Bringing this capability in-house transformed EGO’s workflow. By performing their own feasibility checks, they could provide a well-analyzed design concept to the construction company, saving an estimated two to three months of engineering time and tens of thousands of euros in consultancy fees for each project.

“The technical support team is very fast and responsive,” Julien adds, highlighting the convenience of the in-product support. “Being able to immediately share models for someone else to review is super-convenient, especially compared with spending time uploading files and ticketing systems I’ve experienced before”.

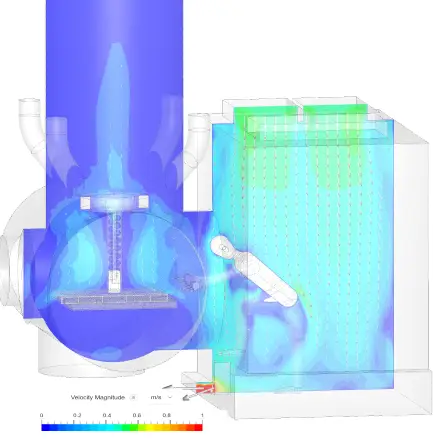

Using SimScale, Julien was able to confront the critical fluid dynamics challenges of the cleanroom design, transforming abstract risks into visible, quantifiable problems that could be solved through simulation.

“We are looking for overall quality of air circulation. We don’t want to see turbulence, which introduces unpredictability, but we also don’t want any dead spots, where dust particles can settle out. The only way to engineer a solution is with a 3D flow simulation that is easy to explore and iterate with.”

Julien Gargiulo

Vacuum Engineer EGO

Julien’s approach was primarily qualitative, using SimScale’s 3D visualizations to gain a holistic understanding of the airflow behavior. The goal was to ensure contaminants were generally pushed down to the floor to be safely removed. The simulations allowed him to experiment with ventilation strategies, combining insights from the analysis with his deep knowledge of the facility to develop effective solutions that could be implemented in the highly restricted physical design space.

Insights gained from simulation allowed Julien to arrive at a well-proven configuration before the detailed engineering design of the chamber was started. “Simulation provides the essential insight we need to be able to position and size vents that clean effectively, but without introducing any large eddies which could re-entrain and deposit contaminants on the optics”, Julien reflects, “it allows us to avoid an immense amount of potential rework and risk.”

By leveraging SimScale’s cloud-native CFD capabilities, EGO successfully navigated a complex design challenge, enhancing the protection of its mission-critical hardware while optimizing for cost and efficiency. The project delivered proactive risk mitigation, moving EGO from a reliance on external contractors to a rigorous, data-driven internal process. The accessible visual outputs also streamlined collaboration and decision-making, fostering a more agile design cycle.

The success of this project has established a new benchmark for facility design at EGO. With further upgrade projects on the horizon, Julien sees a continuing need for simulation to support engineering work. For an organization where scientific progress is paramount, simulation is not just a way to save time and cost, but a strategic capability that ensures project certainty, operational efficiency, and ultimately, mission success.

Set up your own cloud-native simulation via the web in minutes by creating an account on the SimScale platform. No installation, special hardware, or credit card is required.

Sign up for SimScale

and start simulating now