In an era where North American foundries are more often closing than starting out, Demir Engineering stands as a testament to innovation. While the traditional industry has largely moved overseas, Demir has established itself as a new and vital resource, built around a novel technological approach: metal casting in 3D printed sand molds. This process is at the heart of the company, giving them a decisive competitive edge and defining their identity in a challenging market.

Traditionally, casting a metal part requires creating a physical pattern—a positive replica of the component often made from wood or foam—around which sand is packed to create the mold. This process is time-consuming, and the cost of creating the pattern, which can run to $10,000 or more for a moderately sized part, is passed on to the customer as a hefty upfront “pattern fee”. By additively manufacturing their sand molds directly from a CAD file, Demir eliminates this step entirely. This makes them exceptionally cost-effective for the low-volume, high-complexity work that defines their business: creating one-off replacement parts for legacy equipment or prototyping a handful of design variations for a customer seeking a performance advantage.

Increasingly, Demir has become a full-spectrum solutions provider, combining a valuable engineering capability with their in-house foundry to tackle the jobs others cannot. Whether it’s reverse-engineering a component that has been corroded beyond recognition or designing a novel part that pushes performance boundaries, their agile manufacturing process allows them to deliver solutions that are, by their nature, irreplaceable.

Joseph Rodgers, is a Mechanical Engineering Technologist whose role bridges the digital and physical realms. Joseph is responsible for a wide range of design and reverse-engineering projects, with a recent focus on the complex fluid dynamics of pumps and turbomachinery. He explains that simulation is increasingly becoming an integral part of their projects, “our 3D printing process lets us create more complex and more accurate molds than traditional methods, so many of the manufacturability imitations that might previously have been there are now gone”.

This new design freedom opens up the possibility of improving and refining component designs to unlock greater performance and deliver better results for their customers. Without simulation, the team was often limited to creating one-to-one replacements of existing parts, lacking the insight to confidently make improvements.

They needed a tool that could provide certainty, de-risk innovation, and empower them to truly upgrade and optimize their designs. As Joseph explains “simulation offers us a way to explore those possibilities and see what works before we cast anything”. Without simulation, the team was often limited to creating one-to-one replacements of existing parts, lacking the insight to confidently make improvements.

“Simulation gives us the confidence to move beyond one-to-one replacements. It provides the insight we need to not just recreate a part, but to fundamentally improve it.”

Joseph Rodgers

Mechanical Engineering Technologist, Demir Engineering

Joseph’s search for a solution led him to SimScale. As a newcomer to Computational Fluid Dynamics (CFD), the primary drivers for his choice were accessibility and affordability. “There’s two main factors that come to mind,” Joseph recalls. “We needed a solution that was economical and one we could start small with and have it grow with us”. The second factor was usability. “SimScale really looked user-friendly and intuitive, and it has proven to be so… It really helped to cut the learning curve”.

The platform’s cloud-native architecture provided another immediate advantage, eliminating the need for a powerful, dedicated local workstation. Joseph could run multiple complex simulations in parallel on SimScale’s servers while keeping his own computer free for other critical design work. This combination of accessibility, power, and efficiency provided the foundation for Demir to not only improve their existing services but to take on projects they previously would have turned away.

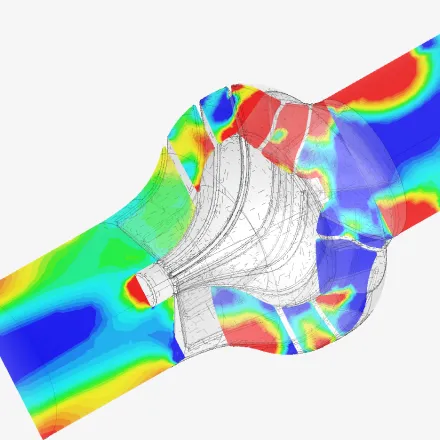

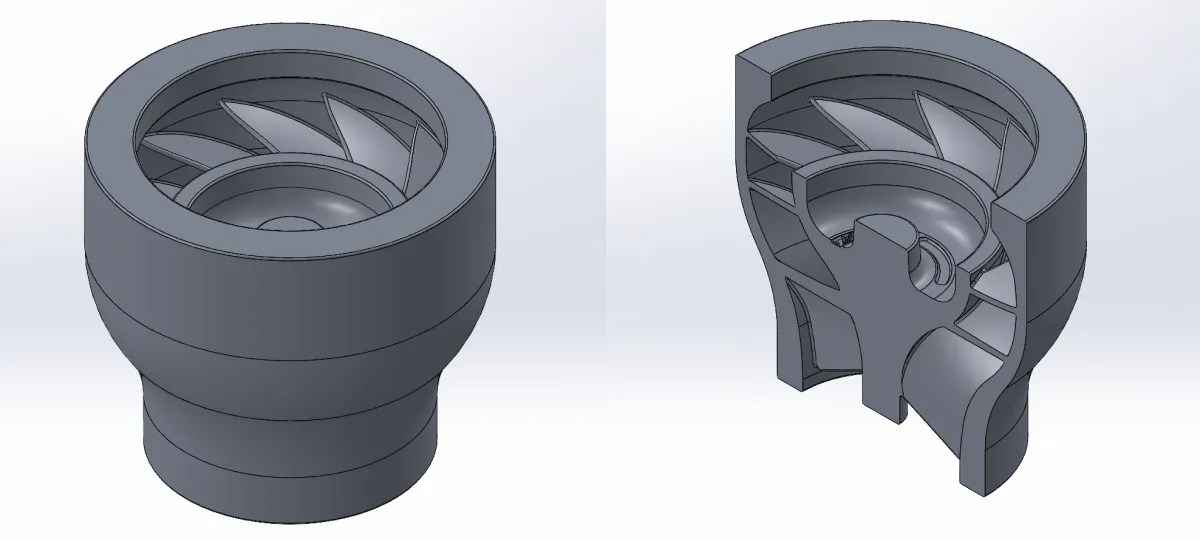

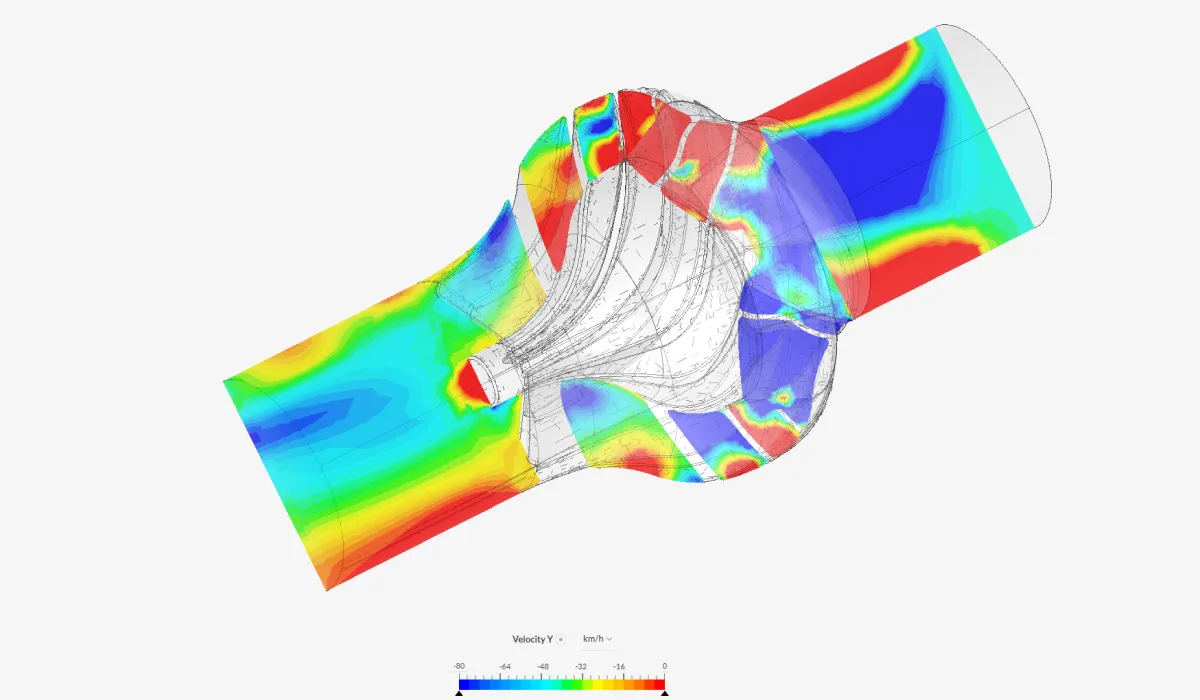

Demir’s simulation capability proved essential when a client requested a replacement for a highly eroded jet drive stator from a racing powerboat. The stator is a critical component that straightens the swirling flow from the impeller, converting it into thrust. The customer, a competitive racer, was looking not only for a replacement aluminium part but also for a performance increase.

Leveraging their 3D printed mold process, the project scope extended to produce four different stator designs – one copy of the original and three experimental designs for added performance. These would be cast in a single mold, allowing for rapid and cost-effective experimentation. Joseph used SimScale to diagnose the shortcomings of the original design, which had been originally produced without the aid of modern simulation tools. The analysis revealed several locations with poor alignment and high turbulence, leading to excessive total pressure losses through the drive.

Armed with this insight, Joseph developed several variations, subtly modifying the vane geometry—adjusting the wrap angle and changing how closely the vanes approached the impeller—to smooth the flow and convert more of the water’s rotational energy into thrust. The best-performing design showed a predicted increase in exit velocity of around 20 km/h—a massive gain in a competitive racing environment. “This isn’t even a project we’d probably try if we didn’t have it,” Joseph admits. “We’d just be shooting in the dark… It’s awesome that we offer our clients this service now”.

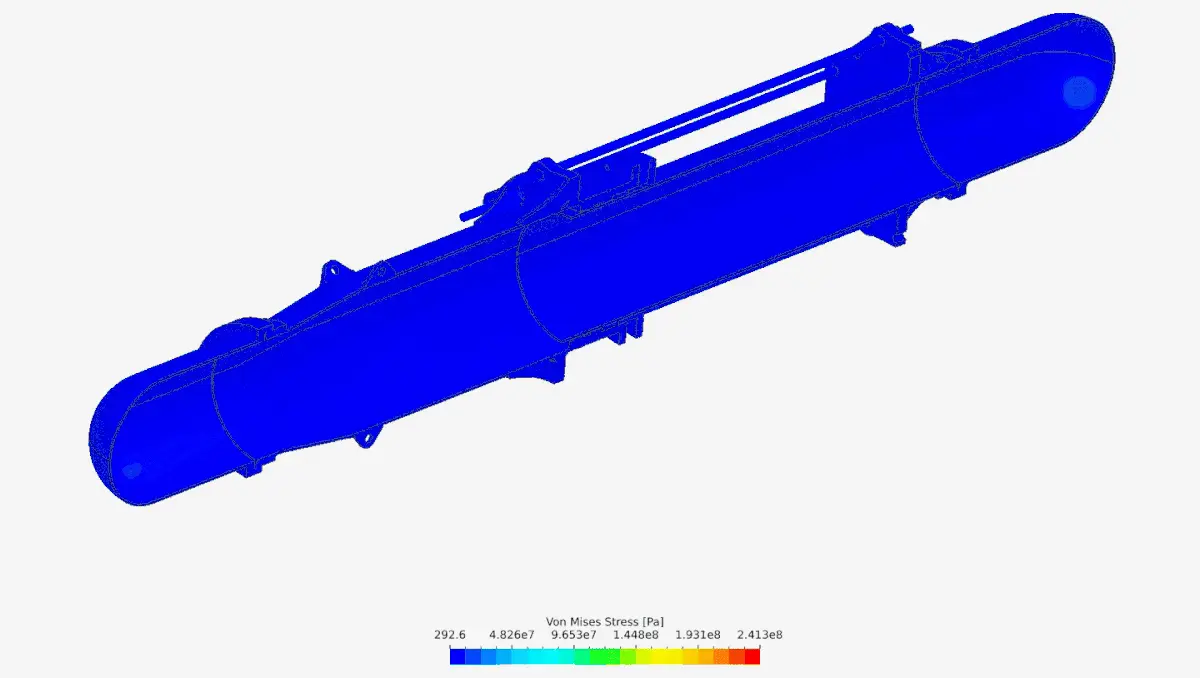

While many of the use cases at Demir are in fluid dynamics, SimScale’s versatility has also proven invaluable for structural analysis. The team was tasked with analyzing a large expansion barrel, a component in piping systems designed to absorb movement from thermal expansion and contraction. The assembly involved two large steel components sliding against a series of PTFE seals, and the team needed to understand the sliding force required to overcome the friction from the compressed seals during a hydrotest.

This type of non-linear analysis, involving large displacement and contact between parts, proved to be a struggle for their standard CAD-embedded simulation tool. In SimScale, however, the setup was far more straightforward. “It seemed very easy to get a meaningful simulation running compared with what I was used to”. SimScale provided the reliable data point they needed, demonstrating its value across different physics disciplines and solving a problem that had stumped other tools.

The integration of SimScale has fundamentally reshaped Demir Engineering’s business. It has given them the confidence to move beyond simple part replication and into the realm of true performance optimization, allowing them to expand their expertise and take on new challenges. By including simulation work alongside their differentiated manufacturing process, they can access the critical data needed to innovate boldly and deliver on their promise to engineer the irreplaceable.

Simulation activity at Demir is on an upward trend. “I only see the space for us increasing,” Joseph says. “It seems to be becoming more and more of our main business”. The team is particularly excited about upcoming platform features for multiphase simulation, where they see applications in slurry pumps in the oil sands and mining industries. By embedding cloud-native simulation at the core of their operations, Demir Engineering is not just surviving in a tough market; they are forging a new, more innovative path forward.

Set up your own cloud-native simulation via the web in minutes by creating an account on the SimScale platform. No installation, special hardware, or credit card is required.

Sign up for SimScale

and start simulating now