Nantoo is an innovative Italian technology startup and part of the Leafcycle project. The core value proposition is that Nantoo tech can transform leaves from waste to a productive resource and it is their commitment to a greener world that drives the level of passion and innovation at Nantoo. The underlying concept is to rethink the concept of waste starting with everyday garden leaves. Leaves are no longer just debris to be discarded but valuable resources to be cherished and utilized. To this effect Nantoo studied the needs of those who care for their outdoor spaces and translated them into innovation and advanced performance leading to the biocycle— the first system designed for 360° care of the garden and outdoor spaces: it vacuums on every surface and vacuum-packs the leaves to 1/10 of their normal volume. The use of computational fluid dynamics (CFD) has been essential to design and optimize the innovative Biocycle product.

Thanks to the revolutionary vacuum function, Biocycle compresses leaves, reducing their volume by 90%. The Biocycle is designed to be ergonomic, lightweight, and easy to handle; it transforms garden maintenance into an effortless activity with a core powered by an advanced brushless motor, a proprietary rotor impeller and a lithium battery, striking a perfect balance between high performance and lightness.

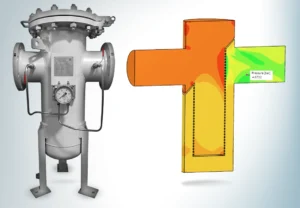

The Nantoo Biocycle is an innovative, powerful yet elegant product that uses an all-cloud product development stack by using Onshape to seamlessly push the CAD model into SimScale. Many aspects of it needed flow analysis using SimScale. The impeller is a highly optimized proprietary design we achieved through simulating many hundreds of design variants. Its ability to collect and vacuum pack leaves to 1/10 of their original volume is unique given how energy efficient and quiet the motor is. We were able to reduce the motor power consumption by 20% by easily applying powerful flow analysis in SimScale to optimize the impeller design.

Beatrice Sileno

Founder & CEO of Nantoo

The engineering team at Nantoo, led by Andrea Taurino the Chief R&D Engineer, has applied SimScale for CFD mainly to optimize the shape of the impeller and the flow/pressure profile of the air inlet and outlet. This approach to optimizing geometries of all components in parallel driven by a six-sigma methodology, has enabled the team to reduce motor power consumption by 20% whilst improving airflow and suction performance by a 10%. A co-benefit has been the allowance to reduce battery size further reducing cost and weight. By arriving at a more converged final design much faster in the R&D process the team has saved 15% of the planned development project length they had originally anticipated.

The technical support from SimScale has been the best I have ever experienced. SimScale’s support engineers shows so much interest, dedication and meticulous detail when helping us to get moving with SimScale quickly. This has been critical for a startup like ours to move faster from the concept to the physical prototyping stage and we have saved 15% of our planned R&D time by using SimScale.

Andrea Taurino

Chief R&D Engineer at Nantoo

Sign up for SimScale

and start simulating now