In the third session of our AI Engineering Bootcamp series, we continued the journey to arrive at the bleeding edge of engineering strategy: building fully AI-native workflows – catch up below and watch the recording to learn more.

Eliminating Bottlenecks

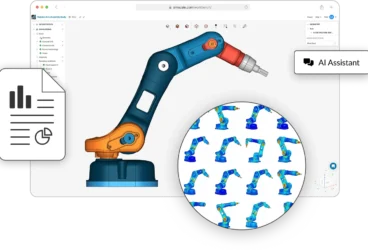

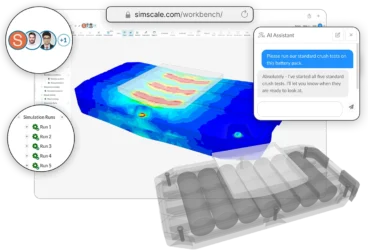

The session brought together three distinct perspectives on how to operationalize AI in production environments: Ram Seetharaman (Head of AI, Synera) on Agentic AI, Matthias Bauer (Director of Software Development, Autodesk / Founder, NAVASTO) on Physics AI, and David Heiny (CEO, SimScale) on the cloud-native infrastructure that binds them together.

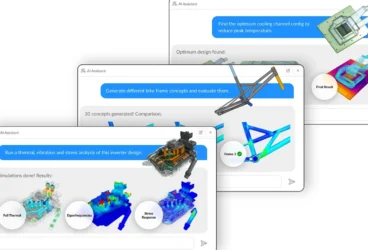

The consensus? The industry is moving past the “chatbot” phase. We are entering an era where AI Agents orchestrate complex tools to automate busy work, and Physics AI provides instant feedback loops, allowing engineers to traverse design spaces at unprecedented speed.

Key Takeaways:

1. Agentic AI is the “Digital Engineer,” Physics AI is the “Calculator”

The session clarified the distinction between the two critical types of AI. Agentic AI (using LLMs) acts like a digital employee—reasoning, planning, and orchestrating tools to handle complex processes like RFQ responses. Physics AI (using GNNs) acts as an ultra-fast solver, providing instant performance predictions to accelerate the design iterations that the agents (or humans) generate.

2. Integration is the Multiplier (The “Electric Motor” Analogy)

Matthias argued that simply swapping a solver for an AI model isn’t enough. He compared it to the industrial revolution: replacing a steam engine with an electric motor didn’t yield efficiency gains until factories were redesigned around the new power source. Similarly, AI only delivers ROI when deep-integrated into the tools engineers already use (like CAD), rather than sitting in a silo.

3. Trust Comes from Traceability, Not Blind Faith

A major barrier to AI adoption is the “black box” problem. The panel emphasized that trust is built through auditability. For Agentic AI, this means viewing the “chain of thought”—seeing exactly which tools the agent used and why. For Physics AI, it means statistical validation and “traffic light” confidence scores that tell an engineer when a prediction is reliable and when to fall back to traditional simulation.

4. The “Junior Engineer” Model

AThe most practical way to deploy AI today is to treat it as a “junior engineer.” It can autonomously handle tedious tasks (like meshing, setup, or initial design sweeps) and present 80% complete work for expert review. This keeps humans in the loop for critical engineering judgments while removing the bottleneck of manual execution.

Watch the full webinar recording below. And if this seems interesting, be sure to check out the rest of the series!