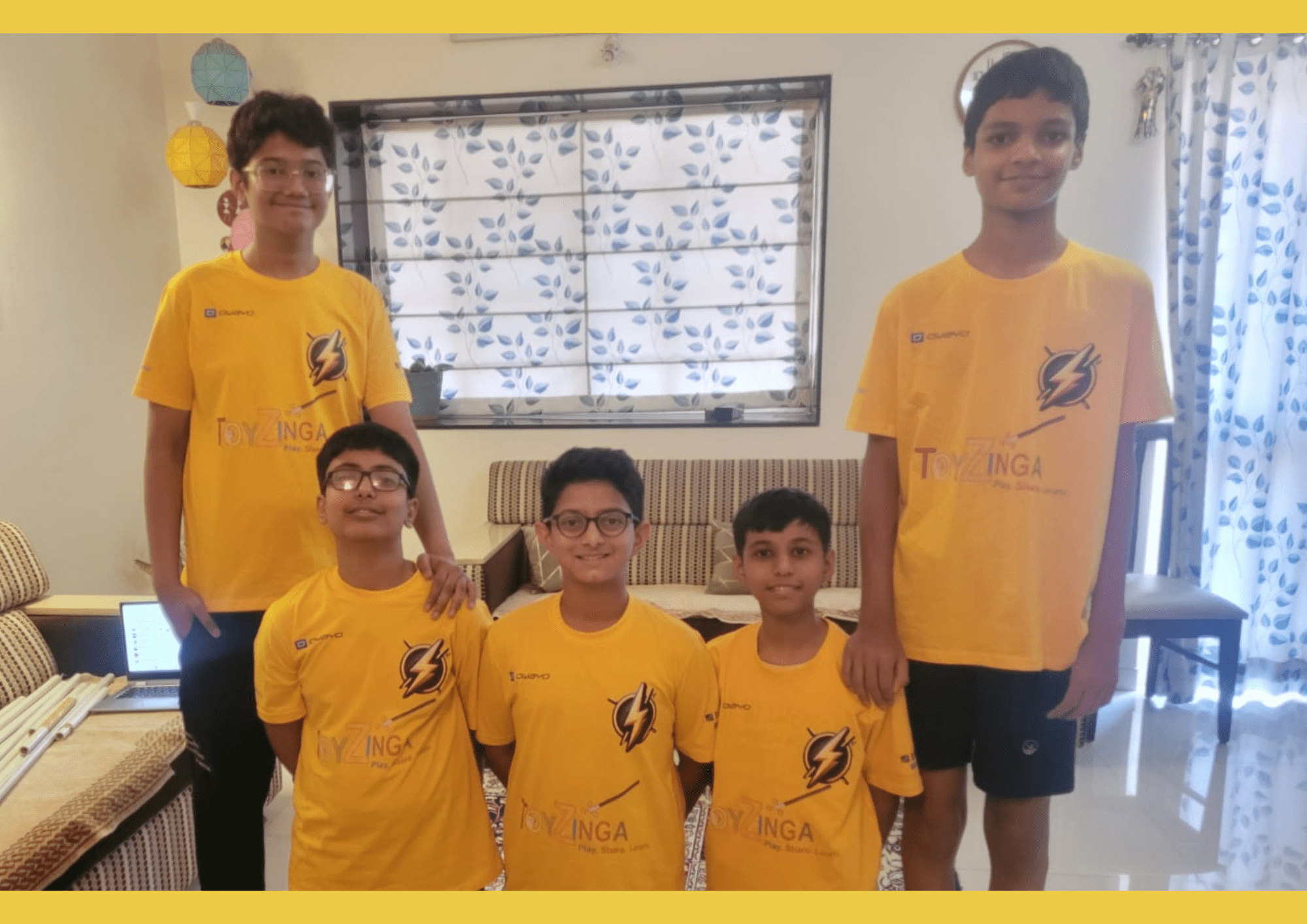

Team Lightning Demons, an enthusiastic and innovative group from Ryan International School, is proudly competing in the STEM Racing competition—the world’s largest STEM program. After qualifying from the West India region, the team advanced to the National Level, securing 7th place and winning the award for Best Engineered Car, along with a nomination for Best Pit Display.

STEM Racing challenges students to design, analyze, and manufacture a miniature Formula 1 car, which is raced on a 20-meter track. Beyond racing, the competition emphasizes key skills such as teamwork, project management, and entrepreneurial thinking.

Design Challenges

To compete successfully, the team needed a fast car—something only achievable through aerodynamic optimization. While physical track testing offers accurate results, manufacturing prototypes was both costly and time-consuming. To overcome these limitations, the team turned to SimScale’s online CFD platform.

Before adopting CAE, they faced several challenges:

- No visual feedback to guide design changes

- Inability to calculate drag and lift forces

- Slow and expensive trial-and-error with physical prototypes

With SimScale, the team gained access to:

- Accurate and fast cloud-based simulations

- A student-friendly, browser-based interface—no installation required

- A wealth of tutorials and learning resources that made onboarding easy

SimScale proved to be a powerful and accessible tool that allowed us to efficiently evaluate and enhance our car’s aerodynamic performance.

– Team Lightning

How SimScale Simulations Led to Success

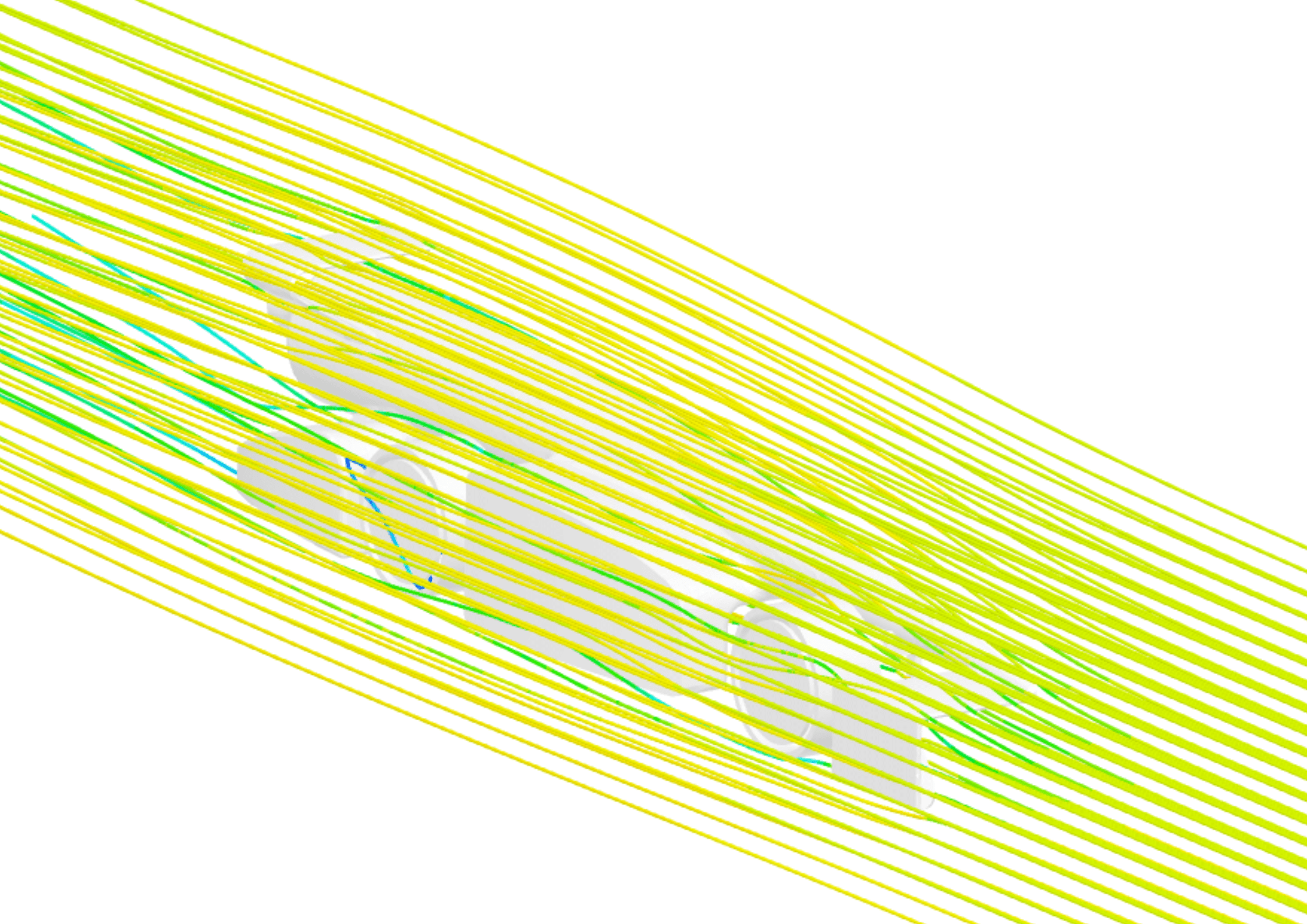

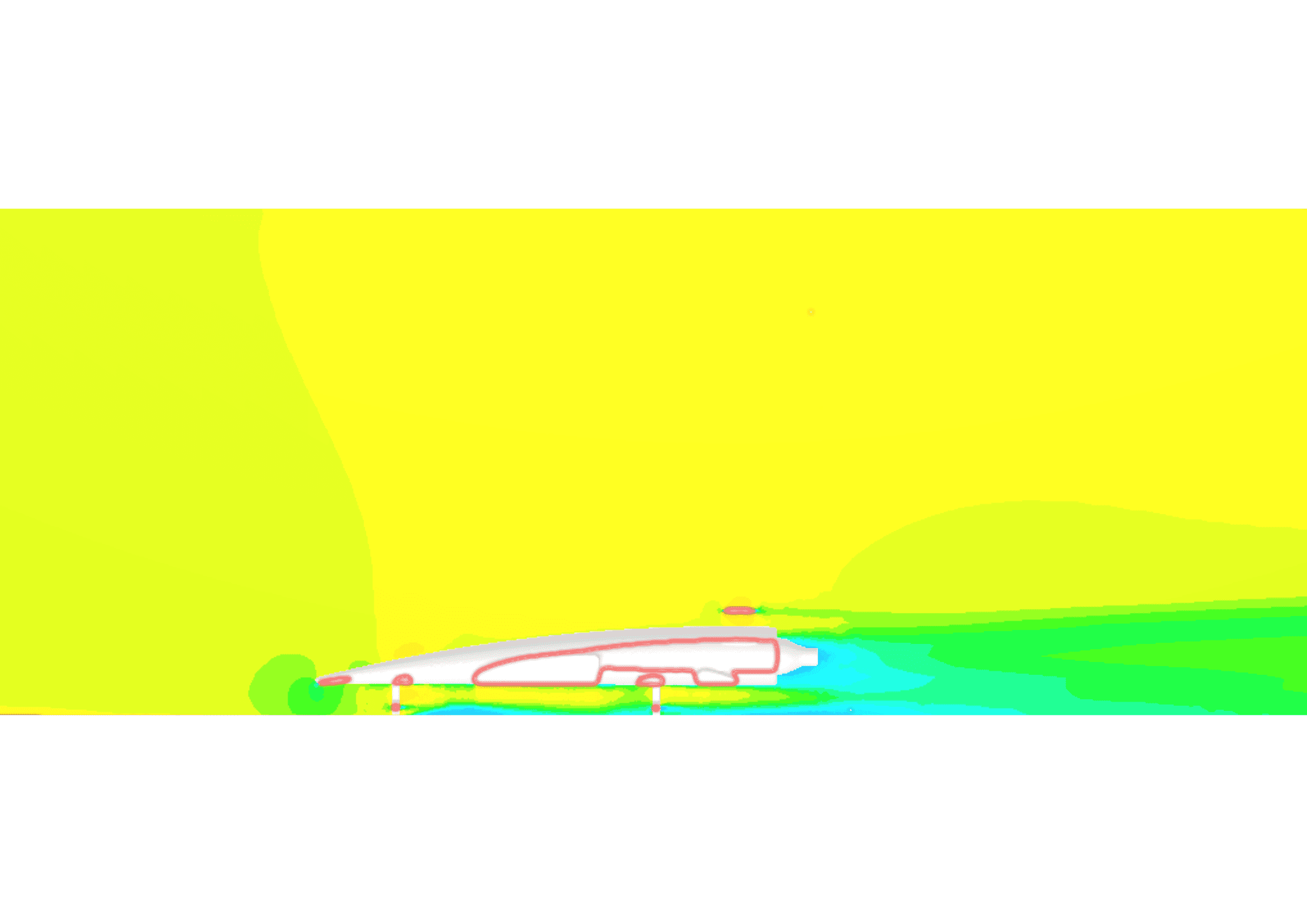

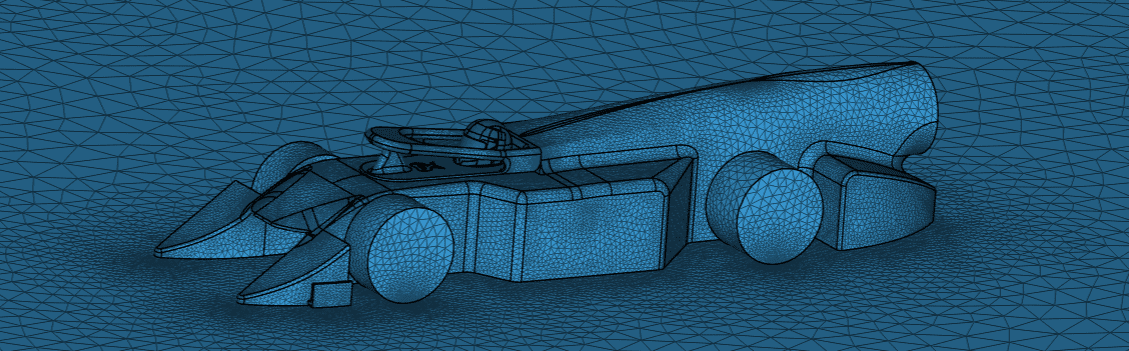

The team imported their F1 car model into SimScale and created a flow volume to simulate a wind tunnel. Using an incompressible steady-state setup, they assigned air as the working fluid and defined key boundary conditions, including a 20 m/s velocity inlet, pressure outlet, and no-slip walls on the car’s surfaces. A hex-dominant mesh with surface and region refinements, as well as inflation layers, was used to ensure accuracy. A forces and moments control was added to track drag and lift throughout the simulation.

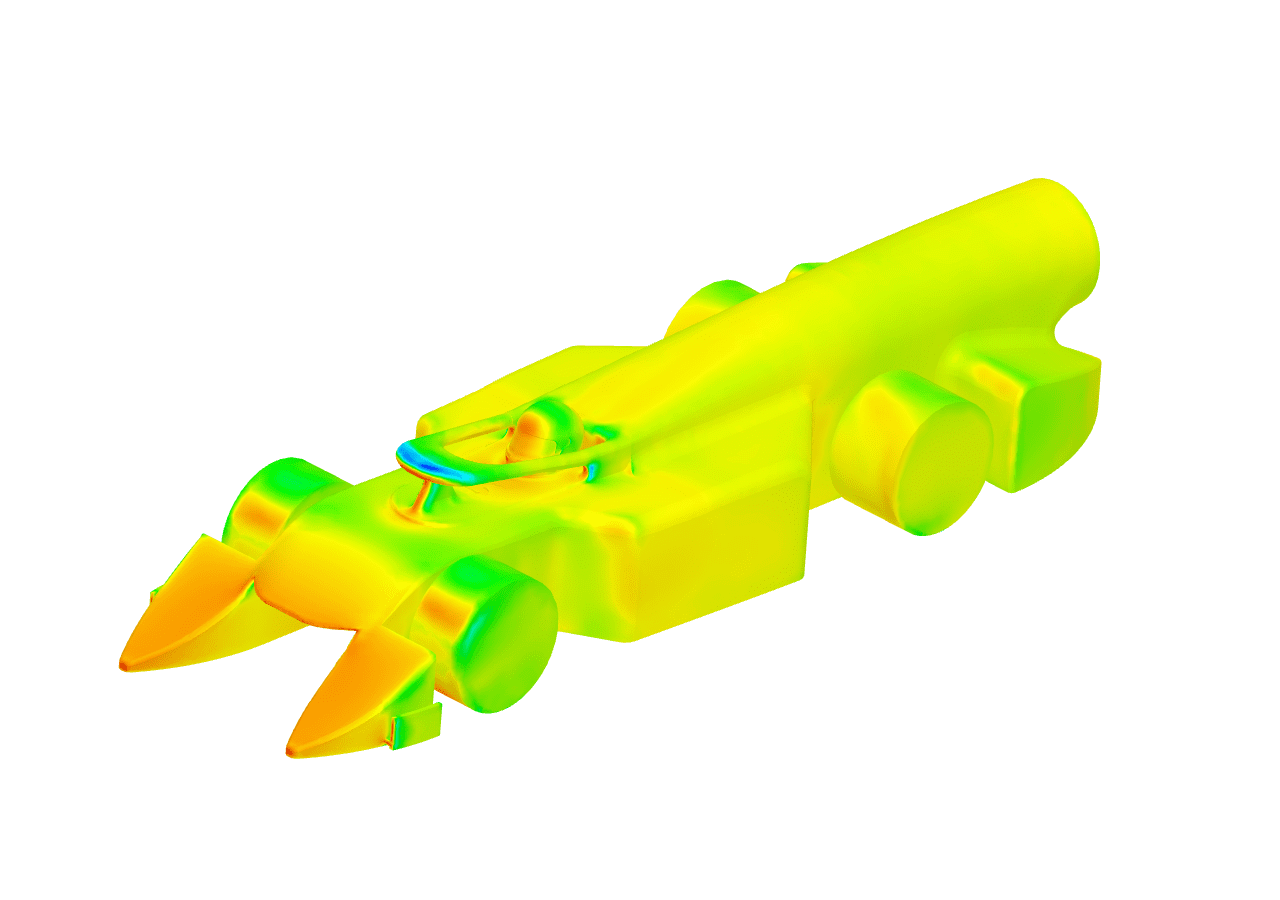

Over the course of development, the team ran 12 CFD simulations, each focusing on refining aerodynamic components such as the nose, side pods, and diffuser. Simulations averaged 25–30 minutes each, with SimScale automatically allocating cores based on mesh complexity. The final mesh contained approximately 1.4 million nodes, using the hex-dominant automatic meshing algorithm at a medium-to-fine fineness level.

SimScale provided the team with detailed results, including velocity planes, pressure distribution, and force coefficients. Particle traces revealed vortex behavior and flow separation, while wall shear stress and velocity contours guided further surface optimizations. The clear visual outputs and reliable data enabled efficient, data-driven design improvements throughout their project.

The team plans to use simulation results to refine key aerodynamic elements such as the nose, side pods, and diffuser, while also conducting FEA to evaluate structural strength. By virtually testing each component before physical production, they aim to ensure a more precise and efficient development process, reducing reliance on trial-and-error prototyping.

SimScale has been a game-changer in our F1 in Schools journey. Their support has been instrumental in helping us develop and refine our car. The cloud-based platform gave us the freedom to run high-quality simulations without hardware limitations, delivering accurate and reliable results throughout the process.

– Team Statement