The New Mandate for Engineering Leaders: Innovate Faster Under Unpreprecedented Pressure

The industrial machinery sector is in the midst of a full-scale transformation, aided by advancements in manufacturing simulation software . For decades, the industry evolved at a measured pace, but it now confronts profound shifts driven by a confluence of global macro trends.

For engineering leaders, the question is no longer how to innovate, but how fast.

The pressures are multifaceted and converging, creating an environment where speed, efficiency, automation and sustainability have become the new pillars of success. Companies that fail to adapt their core processes risk falling out of sync with a market that demands more, faster.

This new reality is shaped by several powerful forces acting in concert:

- Digitalization & Industry 4.0: The demand for digital twins and predictive maintenance requires managing massive amounts of real-time data from interconnected systems.

- Sustainability & Regulatory Pressure: Stricter global regulations on emissions and efficiency make sustainability a core business imperative, requiring scrutiny of every design choice.

- New Power Technologies: The shift to electrification and hydrogen forces a complete rethink of design, balancing performance, weight, energy storage, and cost.

- AI & Machine Learning: Integrating AI/ML for design optimization requires robust data infrastructure and new skills to manage powerful predictive tools.

For the engineering decision-maker, these trends create a core conflict—a difficult balancing act between competing priorities. They are tasked with managing increased product complexity and optimizing production processes while simultaneously shortening design cycles.

They must drive relentless innovation while controlling costs and improving resource utilization in an environment of volatile energy and material prices. And they must deliver ever-higher levels of performance while complying with an increasingly stringent and complex web of global regulations.

This convergence of challenges fundamentally changes the role of the engineering leader. It is no longer enough to be a technical manager.

The modern engineering leader is now a strategic transformer, standing on the front lines of the company’s response to its most critical business challenges. In this high-stakes environment, clinging to outdated development methods is not just inefficient; it’s a direct threat to competitiveness and long-term survival.

From Bottleneck to Accelerator: How Simulation Transforms the Manufacturing Process

To counteract the immense pressures of the modern industrial landscape, leading manufacturers are turning to simulation-driven product development that enhances process flow. This approach represents a fundamental shift away from the slow, linear, and risk-laden process of relying on physical prototypes for validation.

The linchpin of this transformation is early adoption.

When simulation is used not as a final validation check but as an exploratory tool from the very beginning, its strategic value multiplies. This “simulate early and often” philosophy allows teams to identify potential design flaws, test performance limits, and optimize for multiple variables before a physical prototype is built. This virtual testing environment drastically reduces development time and de-risks the entire process.

This approach directly addresses the core conflicts facing engineering leaders:

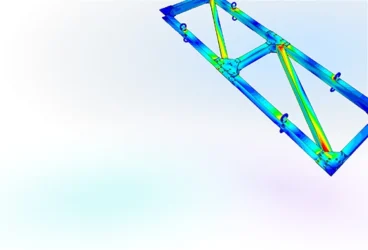

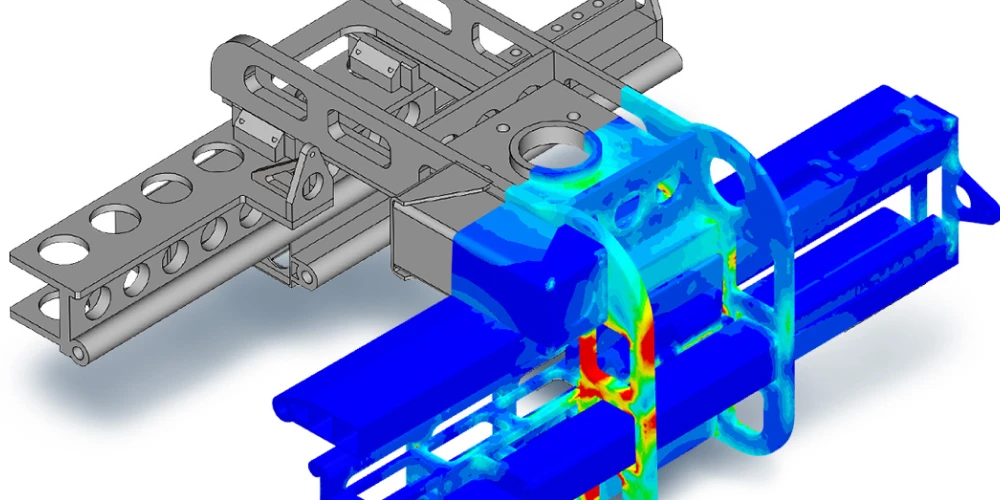

- Tackling Complexity: Simulation allows engineers to analyze the holistic behavior of a system, ensuring all components work together as intended in a way that is impractical or impossible with physical testing.

- Accelerating Timelines: By replacing slow and expensive physical iterations with rapid virtual ones, simulation directly shortens the product development cycle.

- Optimizing for Sustainability and Cost: In a virtual environment, engineers can make data-driven decisions that meet sustainability targets and reduce operational and production costs.

Perhaps the most profound impact of this approach is how it inverts the traditional economics of innovation. Historically, the high cost of physical experimentation has limited exploration and encouraged conservative design choices.

Cloud-native simulation shatters this model.

Consider the case of the Bühler Group, a global leader in manufacturing processing technology. By leveraging simulation, their teams were able to evaluate 60 different design variants for a food processing project in just two weeks—a feat unimaginable with physical prototyping.

This demonstrates a complete inversion of the development funnel. Instead of limiting exploration, simulation enables a massive, parallel exploration of the entire design space at the very beginning of the process. Failures in a virtual world are cheap and provide valuable learning data, which helps to improve quality.

This de-risks innovation and empowers engineering leaders to shift their teams’ focus from simply finding a design that works to discovering the absolute optimal design. This capability is not merely an efficiency gain; it is a powerful strategic weapon.

The Proof: Quantifiable Returns from the Factory Floor to the Bottom Line

The strategic shift to simulation-driven workflows is not a theoretical exercise; it is delivering tangible, measurable business outcomes for industry leaders today. Across the manufacturing sector, companies are leveraging advanced simulation to accelerate innovation, enhance product performance, and optimize resources while achieving significant returns on investment that resonate from the R&D lab to the C-suite.

The evidence is compelling, showcasing dramatic improvements in speed, cost savings, and operational resilience.

Disruptive Speed and Cost Savings

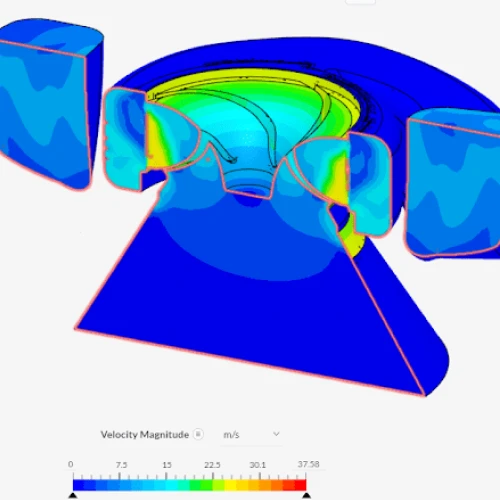

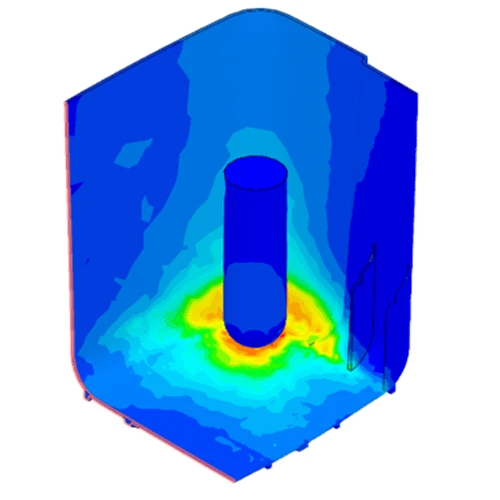

For companies like Hazleton Pumps, a global supplier of heavy-duty pump systems, the adoption of early-stage simulation was transformative. Previously reliant on a slow physical prototyping process, the company embraced simulation to evaluate multiple layout configurations and design configurations virtually.

The results were staggering: a 99% reduction in their development timeline and a savings of $40,000 per pump assembly through value engineering of structural supports.

Simulation (with SimScale) drastically changed our R&D landscape regarding time (99.9% quicker), cost (no HPC and data storage), and simulation accuracy. It allows us to complete development cycles within days instead of months, giving us a massive advantage compared to our competition. I would say that this (software) is not evolutionary but rather disruptive.

— Benjamin van der Walt, Engineering Manager at Hazleton Pumps

Manufacturing Operations Uptime and Crisis Aversion

The value of simulation now extends far beyond the initial design phase into critical plant operations and maintenance. This is where the technology proves its worth not just as a tool for innovation, but as a crucial asset for risk management.

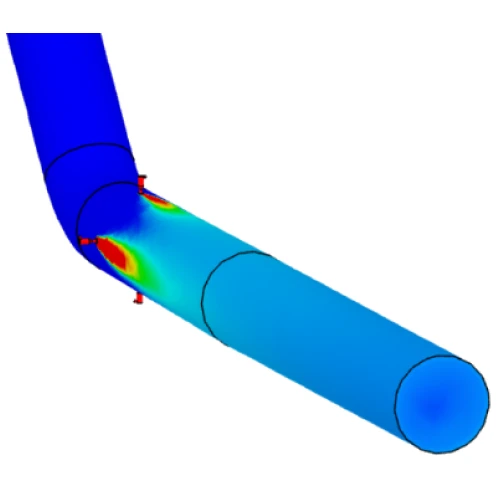

Methanex, the world’s largest methanol producer, faced a potentially high-risk leak in one of its production plants. A forced shutdown would have resulted in massive production losses. Instead of waiting for a physical fix, their Reliability Engineering team used simulation to design and verify a new leak containment component.

They delivered a validated solution in a single business day, with the component itself designed and optimized in just 8 hours. This rapid response avoided a costly plant outage, saving the company an estimated $3.5 million.

Similarly, Nalco Water, a leader in water treatment solutions, used simulation to solve a critical operational issue at a large paper mill in Brazil. A faulty water nozzle was causing repeated, costly downtime. By using CFD simulation to quickly optimize the nozzle design, they achieved a 70% reduction in unplanned downtime, equating to an annual saving of $10 million for their client.

Sustainability Meets Profitability

Simulation is also proving to be a key enabler for companies striving to meet ambitious sustainability goals without sacrificing profitability.

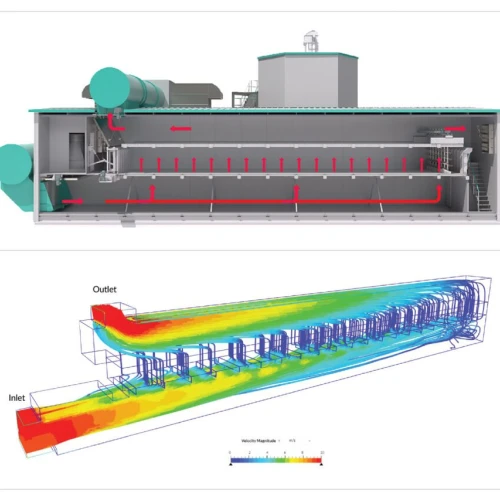

Kreyenborg, a leader in food drying technologies, used simulation to optimize airflow and heat transfer in their industrial dryers. This focus on efficiency and the use of digital models led to a 25% cost reduction in their new designs and shortened their time-to-market by 2-3 months per product.

In Denmark, the design consultancy Böhme specializes in sustainable plastics manufacturing. By integrating simulation into their process design, they were able to provide their customers with solutions that delivered 15% energy savings and 10% material waste reduction, providing a direct and quantifiable return on investment.

These examples, summarized in the table below, paint a clear picture. Modern simulation software delivers a powerful, multi-faceted business case that speaks directly to the core priorities of engineering and executive leadership.

| Company | Key Challenge | Simulation-Driven Outcome | Quantifiable Impact |

|---|---|---|---|

| Hazleton Pumps | Long development cycles; high prototyping costs | Early-stage virtual prototyping and value engineering | 99% reduction in development timeline; $40,000 saved per assembly |

| Methanex | Urgent plant leak; risk of costly shutdown | Rapid design and verification of a containment solution | $3.5 million saved by avoiding plant downtime; 8-hour solution turnaround |

| Nalco Water | Unplanned equipment downtime in a paper mill | CFD optimization of a faulty water nozzle | 70% reduction in unplanned downtime; $10 million/year saved |

| Kreyenborg | Energy inefficiency in food drying technology | Airflow and heat transfer optimization | 25% cost reduction; 2-3 months faster time-to-market |

| Cryo Pur | Slow, iterative design optimization | Parallel computation in the cloud | Simulation time reduced from 26 hours to 1 hour per design |

The cases of Methanex and Nalco Water signal a crucial evolution in the application of this technology. Historically confined to the R&D department, simulation is now being deployed more broadly across the product lifecycle as a critical operational asset for maintenance, reliability engineering, and real-time problem-solving.

This uncovers a new and compelling justification for investment. The ROI is no longer measured just in R&D efficiency gains but in avoided operational losses and protected revenue streams.

An engineering leader building a business case for investment should consider not only how simulation can benefit the R&D and design process, but also how simulation-driven insights can drive operational excellence and predictive maintenance of in-service equipment.

The Technology Shift: Why Cloud-Native Platforms are Outpacing Legacy Tools

The remarkable results achieved by companies like Hazleton Pumps and Methanex are made possible by a fundamental technology shift: the move from traditional, on-premise simulation software to modern, cloud-native platforms. Legacy tools, while powerful in their time, have become a source of frustration and a significant bottleneck for agile engineering teams.

The Legacy Bottleneck

Traditional simulation software is often characterized by inherent limitations that stifle the very innovation it is meant to support:

- Slow and Serial: Long solution times tie up computing resources for hours or days, forcing a slow, serial design process.

- Siloed and Restrictive: Steep learning curves and complex licensing create specialist bottlenecks, slowing down development.

- Hardware-Dependent: Requires massive, expensive investment in on-premise HPC hardware with fixed capacity, limiting simulation scale.

The Cloud-Native Advantage

Cloud-native simulation platforms were built from the ground up to eliminate these bottlenecks. By leveraging the immense power of cloud computing, they offer a fundamentally different approach that aligns with the needs of modern, globally-distributed engineering teams.

- Unlimited Scalability and Flexibility: Provides virtually limitless computational power on demand, allowing engineers to run hundreds of simulations in parallel without hardware constraints.

- Seamless Cloud-Based Collaboration: Accessible via a web browser with built-in collaboration tools, enabling global teams to work together on the same project in real time.

- Comprehensive Multiphysics on a Single Platform: Integrates a full suite of solvers (flow, thermal, structural and electromagnetics) into a single interface, providing a holistic view of system performance.

- Democratized Access and Early Integration: A browser-based interface and templated workflows lower the barrier to entry, empowering more design engineers to use simulation early and often.

- Enterprise-Grade Security: Employs robust encryption and compliance with rigorous standards like SOC 2 Type II to ensure intellectual property is protected.

This transition from legacy to cloud-native is more than just a technological upgrade; it represents a profound organizational and cultural shift. The old model centralized power with a few specialists, creating dependencies. The new, cloud-native model democratizes access across teams and organizations..

At Bühler, 15% of all mechanical and process engineers now use simulation regularly.

This means simulation is no longer a service requested by designers but a tool wielded by them directly.

For an engineering leader, this flattens the organizational structure, accelerates problem-solving, and upskills the entire team. This cultural shift toward proactive, data-driven engineering is a far more durable competitive advantage that can increase throughput than any single software feature.

Expanding the Frontier: Latest Trends and Applications in Manufacturing Simulation

As cloud-native platforms mature, they are enabling engineers to tackle new challenges and push the boundaries of what’s possible, ultimately leading to increased throughput. The application of simulation is expanding beyond product design into a host of cutting-edge areas that are defining the future of manufacturing.

AI and Machine Learning Integration

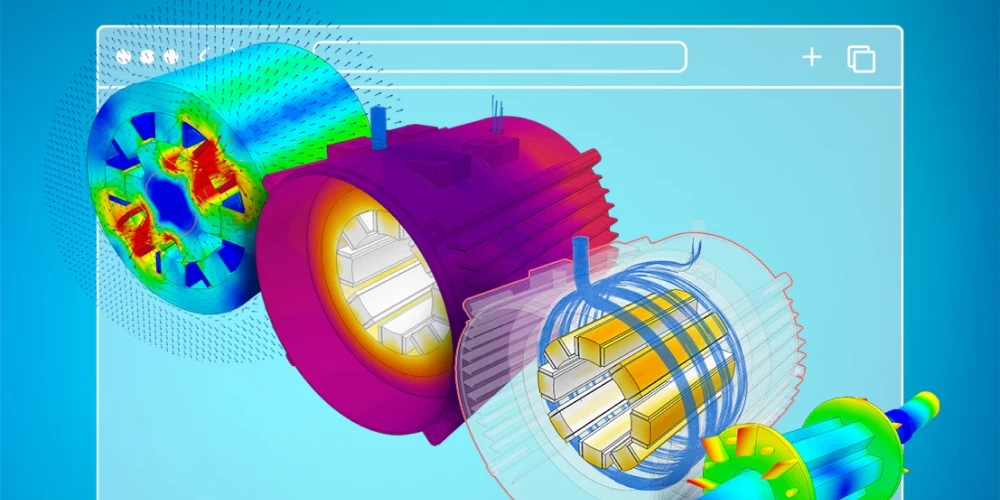

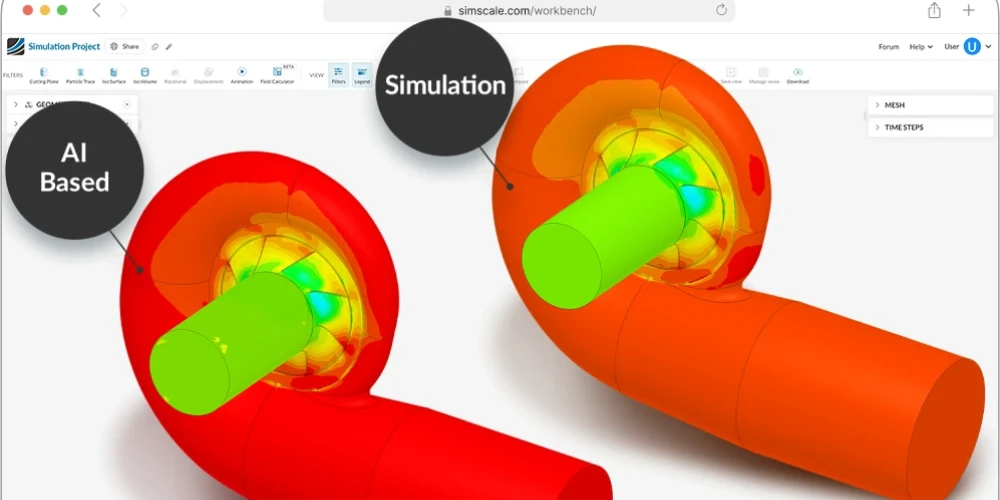

The fusion of physics-based simulation with artificial intelligence is creating a powerful feedback loop that accelerates the entire innovation cycle.

- AI-Powered Simulation: Physics AI models speed up analysis by providing near-instant performance predictions, enabling rapid evaluation of hundreds of early-stage design options.

- Simulation-Generated Data for AI: Simulation generates high-quality synthetic data to train AI models, especially when real-world data is scarce. This creates a symbiotic relationship: simulation makes AI smarter, and AI makes simulation faster.

- Pre-trained Foundation Models: Trained on broad datasets, foundation models provide a ‘quick start’ to help companies start leveraging AI, as well as being a highly effective way to democratize access to simulation-driven insights.

Powering the Green Transition

Simulation is playing an indispensable role in developing the next generation of sustainable technology needed to power the global energy transition.

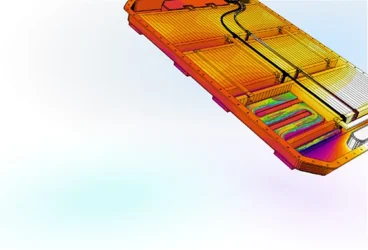

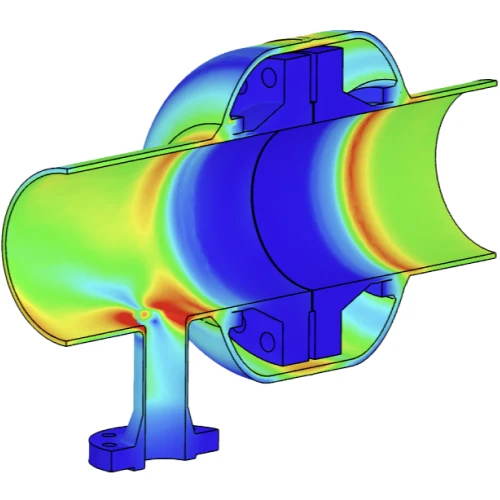

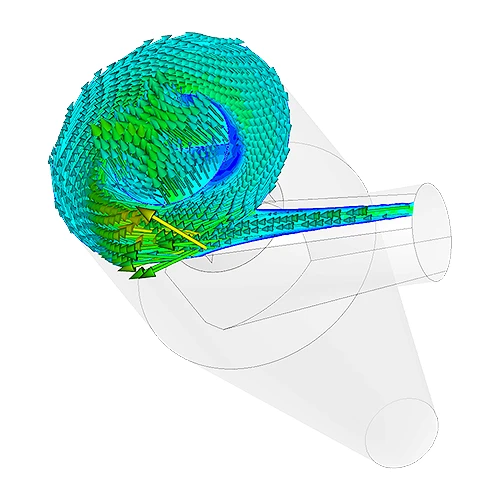

- Electrification and Hydrogen: Simulation helps solve complex multiphysics challenges in designing efficient electric motors, batteries, and hydrogen systems by modeling thermal, electromagnetic, and fluid dynamics.

- Renewable Energy Systems: Simulation optimizes renewable energy tech like Energyminer’s micro-hydropower plants and Cryo Pur’s biogas liquefaction systems, which cut simulation time from 26 hours to just one.

Deeply Integrated, Application-Specific Workflows

Modern platforms are also developing highly tailored workflows that address the specific needs of different manufacturing domains, demonstrating a deep understanding of industry challenges.

- Turbomachinery: Generate full pump curves in under an hour or complete cavitation studies in two hours—tasks that previously took days.

- Valves and Flow Control: Automated calculations for valve coefficients (Cv, Kv) and pressure loss enable rapid optimization of flow control systems.

- HVAC and Built Environment: Optimize everything from heat exchangers to entire building ventilation systems. Fusion Modulair verified the HVAC design for a 55,000 m2 building, ensuring code compliance with a massive 47 million cell mesh simulation.

Future-Proofing Your Engineering Workflow

The pressures facing the industrial machinery sector are immense, but the tools available to meet these challenges have evolved dramatically. Simulation has transitioned from a niche, late-stage validation tool into a core strategic asset for driving innovation, maximizing efficiency, and ensuring inventory control and operational resilience.

The evidence is clear: companies that embrace a simulation-driven approach are innovating faster, operating more efficiently, and building a significant competitive advantage.

Adopting a cloud-native simulation platform is therefore not merely a software purchasing decision; it is a strategic investment in your organization’s future competitiveness. It is an investment in agility, resilience, and innovation for optimizing your production line, giving your engineers the freedom to explore the boundaries of design without the constraints of physical prototyping.

Ultimately, success in this new era will require more than just technology. The most successful companies will be those that foster a cultural shift toward collaboration, agility, and proactive, data-driven problem-solving. By investing in cloud-native simulation today, you are not just acquiring a powerful tool; you are laying the foundation for this culture and investing in your ability to lead, not just react to, the changes that will shape your industry for years to come

Unlock new levels of innovation and efficiency in industrial machinery manufacturing with SimScale’s cloud-native simulation platform.

Get started for free today to explore how early-stage simulation can optimize your designs for performance and sustainability.

For tailored solutions to your specific manufacturing needs, request a personalized demo or consult with our experts to discover how SimScale can help you accelerate product development, reduce costs, and meet evolving industry demands.