HVAC is one of the many industries facing many challenges related to digital transformation and emerging technologies in product and process manufacturing, construction building, or factory and plant infrastructure design.

HVAC equipment and systems are an essential element in a number of areas from home heating and ventilation to industrial ecosystems based on energy savings, thermal comfort, and air quality and noise standards. In the current climate, manufacturers of HVAC equipment must remain at the cutting-edge of industry standards and performance criteria in order to maintain efficiency and control in a very competitive market. In industrial areas, such as factories and plants, the engineering team should work in close cooperation with architects, constructors, and designers, as they fit building plans with adequate infrastructure and utilities.

Due to their complexity and the high-quality standards they must meet, the HVAC systems require intensive testing. In addition to physical prototyping, Computer-Aided Engineering (CAE) ensures maximum design optimization, efficiency, and performance while offering significant cost reductions and control of investment. As the first cloud-based engineering simulation platform, SimScale allows product development team members at all levels to simulate the physical behavior of products or building structures within a standard web browser.

What is HVAC Equipment? 5 Ways to Improve HVAC Designs

Here are 5 applications of simulation of HVAC equipment and numerous ways that 3D simulations with SimScale can be used to optimize HVAC designs:

1. Improve Thermal Comfort

The most common functionality of HVAC equipment is related to maintaining and optimizing thermal comfort. But what does “thermal comfort” mean? And which metrics should we consider when carrying out an optimization analysis?

Ventilation and heating equipment is installed in many places, from home apartments, cars, any vehicle cabin, school classrooms, office and meeting rooms, entertainment spaces such as restaurants or cinemas, to industrial facilities dedicated to computer servers, manufacturing machines, warehouses or industrial heating equipment. Any thermal comfort analysis for an indoor space or industrial facility should make adequate considerations with regards to equipment optimization and ventilation air control.

Although the air temperature is the most commonly used indicator in thermal comfort analysis, it is vital that it is considered in relation to other key environmental and personal factors. The factors affecting thermal comfort are both environmental (such as air temperature, radiant temperature, air velocity, and humidity) and personal (such as clothing insulation and metabolic heat) [1].

These factors may exist independent of each other, but together they all contribute to the general thermal comfort of the environment. The environmental factors can be controlled by the HVAC equipment and the optimal thermal comfort is provided only if the heating, ventilation, and air conditioning systems are well-designed to meet all specific indoor conditions. While air temperature is easily controlled, the radiant temperature has a greater impact on how heat is lost or gained within the environment. Air velocity and humidity are also important factors to consider when optimizing thermal comfort.

Considering all these factors and identifying a sufficient solution for them requires testing in a virtual environment. 3D engineering simulation (CAE) is the technology that is helping HVAC engineers design, analyze, and optimize key elements such as AC, heating, and ventilation systems.

Let’s take a look at an HVAC equipment simulation example available in the SimScale Public Projects:

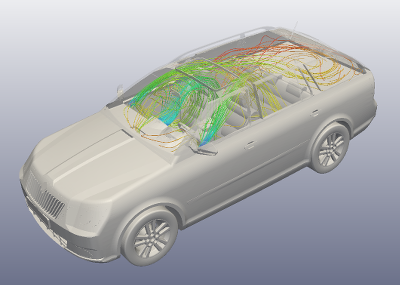

In this project, a steady-state, natural convective heat transfer analysis was carried out to simulate the internal airflow. The geometry includes a standard, wagon type, four-door car that is modified for internal flow analysis. The cabin interior has four front inlet air conditioning ducts and one outlet vent on the hood. The initial car temperature was 30°C, and the temperature of the airflow was set at 10°C. The final results demonstrate the airflow velocity contour through the cabin and the temperature.

Another similar project available in SimScale Public Projects is this analysis of the ventilation in an aircraft cabin, in which two configurations and their effect on the airflow pattern are illustrated.

2. Save Energy

Energy consumption in data centers and server rooms is a critical issue that the IT industry has been striving for decades to improve. The exponential growth of information volume related to data center globalization and cloud computing infrastructure require vastly more powerful equipment and more complex IT services. In the past, the focus was placed on energy-saving measures, and the primary strategy was to build effective solutions for power supply and cooling. New measures addressing IT hardware efficiency are now at the forefront, and they are primarily focused on hardware and power management energy-saving strategies [2].

Energy consumption is driven by the number and the hardware capacity of IT rooms in office buildings, including servers, networking equipment, data storage racks, and the cooling and power conditioning infrastructure that support them. In many cases, the infrastructure within a data center is using more energy annually than the traditional HVAC and lighting loads found in normal office buildings. A survey conducted by Uptime Institute shows that 30% of servers in data centers are unused, each one costing over $3,000 per year in energy, space, and maintenance costs.

Economic reasons and energy-saving policies have forced IT and energy engineers to find better ways to control the energy use of IT solutions. They now seek innovative and effective ways to save money and reduce pollution with efficient airflow management and HVAC equipment adjustments. Between most recommended hardware and software solutions, any CIO should give serious consideration to the following optimization tips for reducing the energy costs of a server room [3]:

• server infrastructure improvement by using virtualization systems which can reduce the number of required physical machines

• server management software that can substantially reduce the IT power load

• equipment with internal temperature-controlled variable-speed fans (VSDs

• equipment with internal/external power management to optimize energy consumption

• reporting systems that can send temperature and power/energy consumption data to a Building Energy Management System.

For airflow management strategies, here are some recommendations from ENERGY STAR [4]:

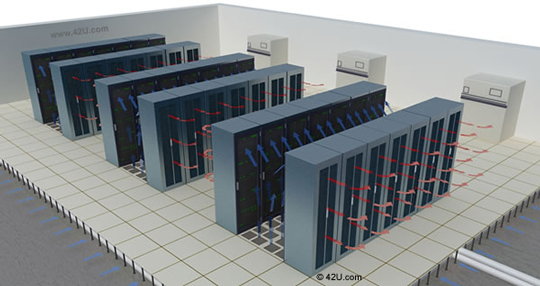

- Hot Aisle/Cold Aisle Layout – Special equipment arrangements can be implemented to lower cooling costs by better managing airflow. These strategies accommodate lower fan speeds and increasing the use of air-side or water-side economizers. When used in combination with containment, the US Department of Energy estimates a reduction in fan energy use of 20% to 25% [5].

- Containment — Refers to the various physical barriers used in addition to a hot aisle/cold aisle arrangement. Containment further eliminates the mixing of cold (“supply”) air and hot exhaust air. Containment structures lead to higher allowable temperatures in data centers. Higher temperatures save energy because fan speeds can be lowered, chilled water temperatures can be raised, and free cooling can be utilized more frequently.

- Variable Speed Fan Drives — Computer Room Air Conditioning (CRAC) unit fans consume a lot of power and tend to account for 5% to 10% of a data center’s total energy use. Most CRAC units are not capable of varying their fan speeds in response to the data center server load, which tends to fluctuate. Because data center environments are in constant flux, variable-speed fan drives should be used wherever possible. Retrofits of many CRAC units are available.

- Properly Deployed Airflow Management Devices — All airflow management strategies strive to either maximize cooling by supplying cooling (“supply”) air directly to equipment, or by eliminating the mixing and recirculation of hot equipment exhaust air. A study conducted by the Uptime Institute across 19 data centers concluded that only 60% of the cool air produced by cooling equipment was pumped into the data center. According to the American Society of Heating, it was also found that 10% of the data centers had hot spots (server too hot or too dry).

Fortunately, many problems can be solved by making simple HVAC equipment adjustments:

- Server Inlet Temperature and Humidity Adjustments — In 2008, the American Society of Heating, Refrigerating and Air Conditioning Engineers (ASHRAE) expanded the recommended temperature range at the inlet of the server from 68°F to 77°F (20°C to 25°C – the 2004 level) to 65°F to 80°F (18.33°C to 26.66°C). However, many data centers typically set their temperatures as low as 55°F (12.77°C). As a result, many of them can save energy simply by raising the thermostat.

- Air-Side Economizer — Could bring outside air into a building and distribute it to the servers. Instead of being re-circulated and cooled, the exhaust air from the servers can simply be directed outside. If the outside air is particularly cold, the economizer may mix it with the exhaust air to create a temperature and humidity that falls within the desired range for the equipment.

- Water-Side Economizer — Uses the evaporative cooling capacity of a cooling tower to produce chilled water which can be used instead of the chiller during the winter months. A chiller is a machine that removes heat from a liquid via a vapor-compression or absorption refrigeration cycle. This liquid can then be circulated through a heat exchanger to cool air or equipment as required. Water-side economizers offer cooling redundancy because they can provide chilled water in the event that a chiller goes offline. This can reduce the risk of data center downtime.

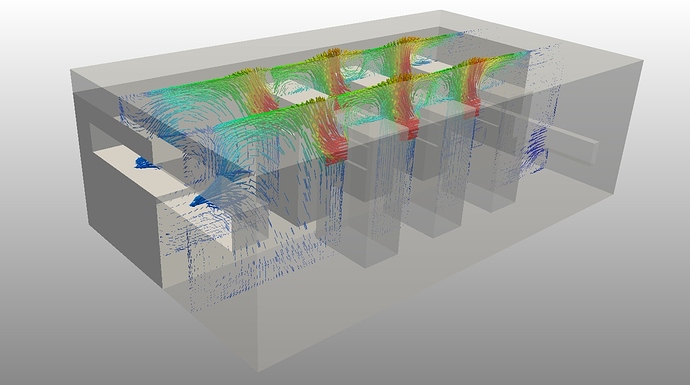

In SimScale’s Public Projects we can find a server room cooling analysis showing how the cooling of a room can be simulated using a SimScale thermo-fluid analysis. The room’s CAD model uploaded in STEP format is meshed using the highly automated hex-dominant meshing operation for internal fluid flow. Two different simulations have been set up. The first simulation assumes a laminar flow field as a rough estimation and the second uses a k-epsilon RANS turbulence model.

Different boundary conditions have also been used; in one simulation, the walls of the room have been assumed to be adiabatic, in the other simulation, the walls were assigned a fixed temperature.

The simulation results allow the necessary power of the cooling system under different operational conditions to be evaluated. It also provides a detailed look at the resulting velocity and temperature field inside the server room. This shows how different layouts of the server room—including the ventilation and air conditioning system—can be evaluated at the very early design phase, postponing physical testing for a later stage of the product development.

Download this case study for free to learn how the SimScale CFD platform was used to investigate a ducting system and optimize its performance.

3. Enhanced Efficiency of the HVAC Equipment

Efficiency improvement is more often related to the design of more efficient ventilation systems. One of the trends for increased heating efficiency is passive houses, which don’t require classical building heating due to their excellent thermal insulation. However, these houses need a complex ventilation system, something which is often a point of criticism because it doesn’t allow a natural fresh air supply. An innovative approach that guarantees a fresh air supply and adequate heat distribution across all rooms is a system that focuses on the use of dual outer walls.

Through skillful design and planning, the air hull surrounding the building can be used to control temperature and air distribution without the installation of ventilators. This solution is only based on the stack effect. The convective flow effects can help to achieve both cooling in summer and heating in winter.

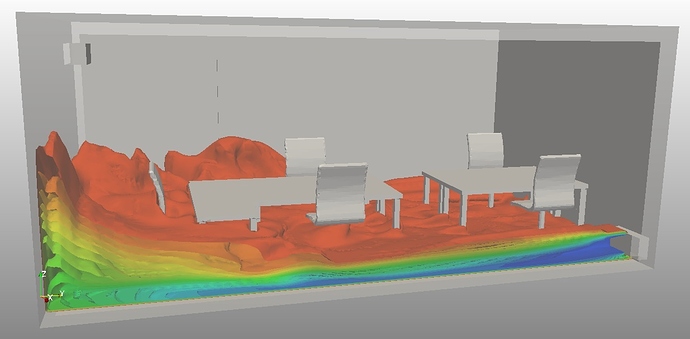

Another very common topic in HVAC equipment design is improving the air quality. SimScale Public Projects include a simulation of air conditioning in an office space.

In this project, the CAD model of the air domain of the office space was uploaded as a STEP file to the SimScale platform and meshed using the automatic hex-dominant mesh operation. The analysis was set up using the natural convective heat transfer analysis type.

A simple boundary condition setup was chosen (fixed temperature at the walls and inlet, fixed inlet velocity condition), but one could easily apply other boundary conditions such as a warm or cold window and adiabatic walls. The image above shows a temperature contour plot which indicates points within the office space where it is warmer and colder.

4. Reduce the Noise Level of HVAC Systems

Effective noise reduction is an important factor in creating a more pleasant living and working environment. The most common sources of noise pollution in any building are related to fans, variable air volume systems, grilles and diffusers, rooftop units, fan coil units, chillers, compressors and condensers, pumps, standby generators, boilers, and cooling towers.

The alternative solutions for noise reduction include using silent ventilation equipment, protecting HVAC equipment and components with silencers and insulation materials, or implementing a noise optimization analysis.

5. Boost Performance of Industrial Heat Exchangers

Heat exchangers are devices with the primary function of transferring (exchanging) of heat, typically from one fluid to another. These heat exchangers are not only used in heating applications, such as space heaters, but also in cooling applications, such as refrigerators and air conditioners. [6]

Many types of heat exchangers can be distinguished based on the direction of the liquid flow.

In such applications, the heat exchangers can be parallel-flow, cross-flow, or counter-current. In parallel-flow heat exchangers, both fluids move in the same direction, entering and exiting the exchanger side by side. In cross-flow heat exchangers, the fluid paths run perpendicular to one another. In counter-current heat exchangers, the fluid paths flow in opposite directions, with each exiting where the other enters. Counter-current heat exchangers tend to be more effective than other types of exchangers.

According to MIT [7], there are three heat transfer operations that need to be described:

• Convective heat transfer from fluid to the inner wall of the tube

• Conductive heat transfer through the tube wall

• Convective heat transfer from the outer tube wall to the outside fluid

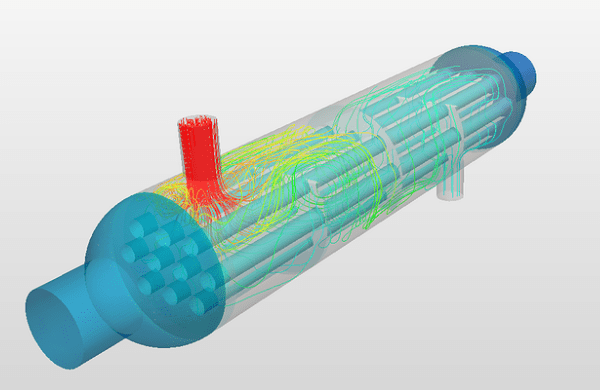

This conjugate heat transfer analysis of a heat exchanger represents an example of how certain phenomena involved in heat exchangers can be simulated with SimScale.

This project contains an excellent analysis of the shell and tube heat exchanger. We have a solid pipe volume and two fluid volumes with one fluid flowing inside the tubes and other inside the shell.

After uploading the CAD file, the Hex-dominant Parametric mesh was used to generate the mesh for the three volumes (one solid and two fluids). This was used to create further refinements and maintain the volumes as different regions to later define interfaces.

A laminar steady-state simulation was then carried out using the ‘Conjugate Heat Transfer’ solver. The outer fluid is considered to be at a higher temperature. The picture above shows a post-processing image representing the streamlines of temperature.

All projects described in this article can be imported into your own workspace for free to help you start your own simulation with minimum effort. Also, you can watch the recorded webinars to learn from SimScale experts how to start with simulation for HVAC equipment and applications.

References

- “The Six Basic Factors”, Health and Safety Executive/ Guidance/ Thermal comfort

- „Energy efficient IT and infrastructure for data centers and server rooms”, PrimeEnergy IT Project Consortium, July 2011

- “Guide to ICT – Server Room Energy Efficiency”, Public Sector ICT Special Working Group, Sustainable Energy Authority of Ireland

- Energy Star – „12 Ways to Save Energy in Data Centers and Server Rooms”

- “Best Practices Guide for Energy-Efficient Data Center Design”, Energy.gov, Office of Energy Efficiency Renewable Energy, revised 2011

- „Use of random noise for online transducer modelling in an adaptive active attenuation system”, Erikson l.J., Allie M.C, Acoustical Society of America, 1989

- “Thermodynamics and Propulsion”, Thermodynamics Course Notes, Massachusetts Institute of Technology.

- Featured image photo source: FreeImages.com/Sue Byford