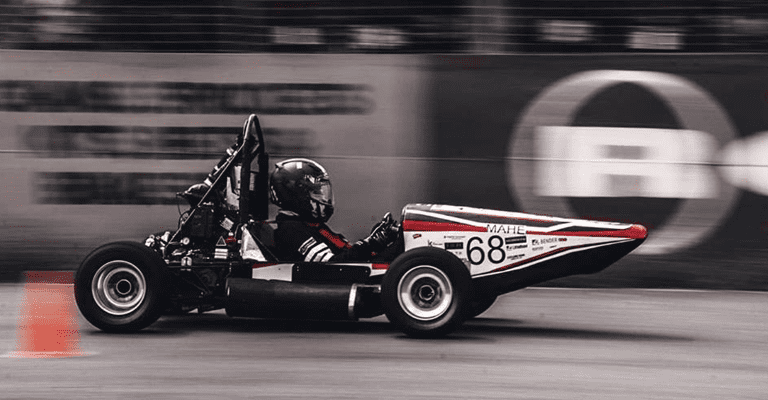

For this student success story, SimScale interviewed Sujay Bhaumik who is an aerodynamicist in the Formula Student team “Formula Manipal“. Sujay is currently pursuing a B. Tech degree in Mechanical and Manufacturing Engineering from Manipal Academy of Higher Education. Along with this, he is responsible for the design and analysis of the undertray, front wings, and rear wings of the combustion vehicle and the optimization of the named parts.

“Our combustion vehicle secured an overall rank 3rd in Formula Bharat. Following this, our upcoming goal is to compete in the international event such as FSG or FSA and do our best.” – Sujay Bhaumik

Formula Manipal is a student project which involves a handful of students to work together to build a Formula style race car. Their team is involved in making one combustion engine car as well as one electric car. They first learned about SimScale from attending a webinar about CFD simulations.

The Problem: Simulating Aerodynamic Properties

The team wanted to run simulations of the various aerodynamic devices such as the front wing, the rear wing, and the undertray that could be used by a formula-style race car. The goals were to:

- Obtain the downforce and drag values of the aero devices.

- Optimize these devices by pursuing the iterative design and analysis process.

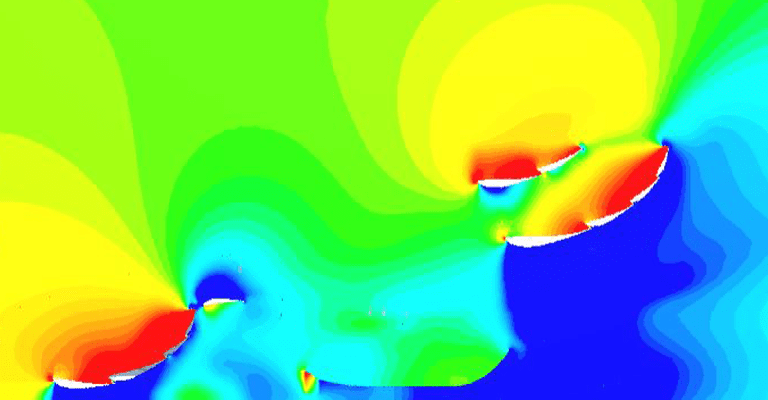

- Observe the varying downforce and drag values along with pressure and velocity contours and streamlines.

Through CAE and namely SimScale, Formula Manipal was able to keep an eye on the future by predicting accurate results in most cases by using their physics models. This saved a lot of time, money, and resources before going to wind tunnel testing and proceeding to manufacturing.

How They Solved It With SimScale: CFD Simulation

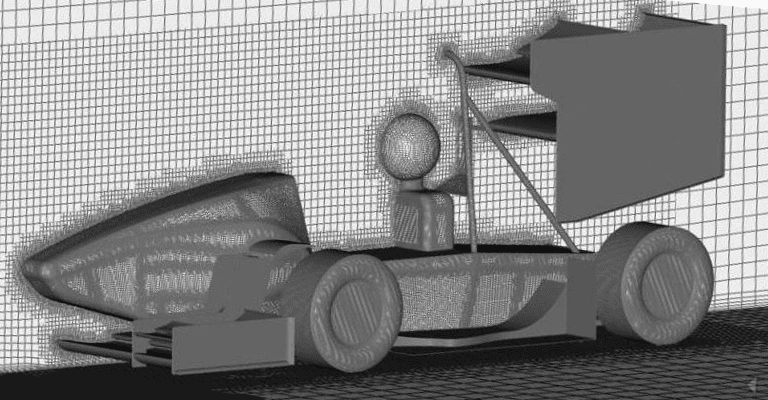

“We used CFD, particularly the “incompressible flow analysis” module inside SimScale. This included the meshing and simulations of the full car with aerodynamic devices.”

The basic setup involved using CATIA V5 for CAD by making use of wireframe surface design, part design, and assembly design. SimScale aided the team through not only the meshing of the domain along with the race car but also through the CFD analysis. The meshing was done facing a trade-off between high-quality mesh (finer feature, surface refinements, boundary layer, etc.) and conserving core hours.

“With the help of SimScale, we were able to do the required simulations, both with better quality and commensurate quantity.”

The team was unable to run other CFD software as they would require more computation power which was not being met by their system’s requirement. This hindered their analysis process, allowing no way out of this problem. SimScale was the only software that provided Formula Manipal with cloud computation, which helped them finally overcome this issue efficiently.

Results and Next Steps

In total, the team ran 43 simulations on the rear wing, 93 on the front wing and undertray, and 11 full-body simulations. It took 208 minutes for the meshing to be completed, and 380 minutes for the simulation of one full-body that involves rotating tires.

Formula Manipal obtained the pressure contours on several sections using the “Cutting Plane” option in SimScale, which helped in the analysis of the aero devices in the essential sections.

“Due to the computation power made available by SimScale, it was possible to meet the deadlines before our design freeze and move to the manufacturing phase without facing any delays. It also helped us to optimize the designs a lot in the limited time available. It gave us a huge boost in our design and analysis process.”

The current goal for the aero team is to work on the cornering simulation of the full-body, as the aerodynamics is beneficial in cornering. This is a big step for the Formula Manipal team, as the car which wins the corner wins the race. Future designs will be based on the outcome of these simulations.

If your team is interested in an academic sponsorship to enhance the performance of your vehicle, no matter if it is in Formula Student or any other competition that we sponsor, make sure to check out the Academic Plan.